Introduction, Scope, and the Purpose of the Model

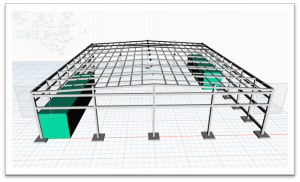

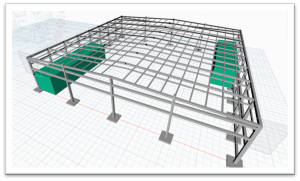

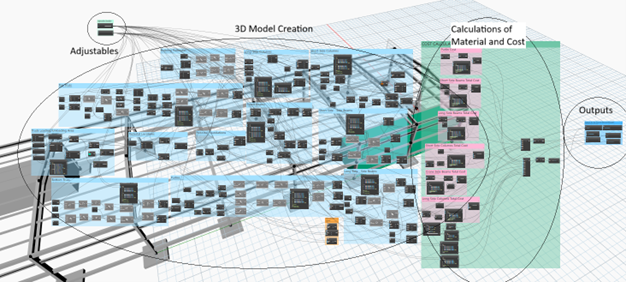

Fig.1 3D Model in Dynamo

This parametric model is intended to aid in decision-making for optimizing functionality and construction costs for a new warehouse. A key aspect of industrial building design is aligning the structure with its intended use (O’Bryne, 2023). The model allows users to compare design options based on key performance criteria, including total storage space, layout, steel and concrete costs, and truck entrance locations.

The model evaluates six design options based on combinations of two-column spacing options and three layouts. Costs are dynamically calculated and displayed, alongside truck entry adjustments and layout summaries to inform stakeholders about storage utilization. Additionally, the 3D structural model updates with user selections, aiding other design teams (e.g., mechanical, electrical, fire suppression) in their configuration processes.

Fig.2 Dynamo Script of Parametric Model

1. High-Performance Criteria and Initial Design

The high-performance criteria evaluated in this model are functionality, minimum material use (sustainability), and minimized construction cost. Since the building is an industrial warehouse storage building, the design challenge is to provide a model that allows the selection of the best layout for operations while keeping construction cost and structural material used at a minimum. The design already includes some considerations to achieve these high-performance criteria.

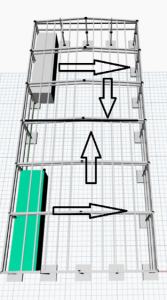

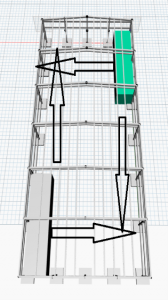

- Interior space is column-free, ensuring the largest space possible is provided.

- The column-free interior also enables the gantry cranes to travel the whole section of the building, with support beams of the cranes being on the sides of the building.

- The height of the building is kept just above the minimum clearance for the cranes

- Two truck entrances placed in diagonal corners ensure to get the best of the layout.

Fig.3 Crane Paths Comparison

2. Design Challenge and Related Design Parameters

The total building layout area is 1600 m2. The shape of the land, allows buildings to be figured in various layout options varying between a 40-meter wide square and an 80 by 20 rectangle. To see the extremes of the design options and to provide simplicity for decision-making, the model evaluates the design under 2 far-end options of 40×40 and 80×20, and one middle option of 60×26.67 meters which can be adjusted within.

Additionally, the column spacing can be changed between 5 meters to 10 meters along the long side of the building. This enables for more windows, bigger uninterrupted truck entrances, and other configuration options. Including exterior components such as more windows and illumination, and bigger uninterrupted truck entrances. Also, other configuration options for other building systems such as operational, mechanical, electrical, etc.

3. Intended Users

Intended users of this model are the stakeholders of the project, consulting firms, and the design teams that are working on this project. In other words, any person who is involved in the decision-making process of the overall design can use or help to build this further. The model provides a great ground to make decisions with the current parameters and the information. It can also be used for other design teams to figure out clearances, and operational teams on the layout.

Logic of the Model

Fig.4 Script and Logic of Model

The model follows a simple methodology, in the adjustable variable section (Image-3 below) there are 2 variables that you can change which are connected to all the node trees in different groups.

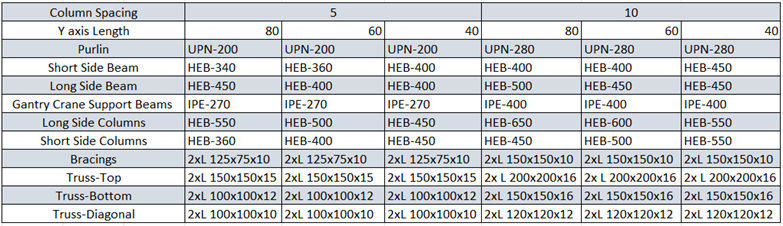

As you change the layout and column spacing, the structural steel sizes, truck entrance locations, storage unit layout, and overall cost (which is calculated in dynamo simultaneously), all change with these variables. Below here is a table of steel components selected for each layout and spacing option.

Fig. 5 Steel Components for each Layout Option

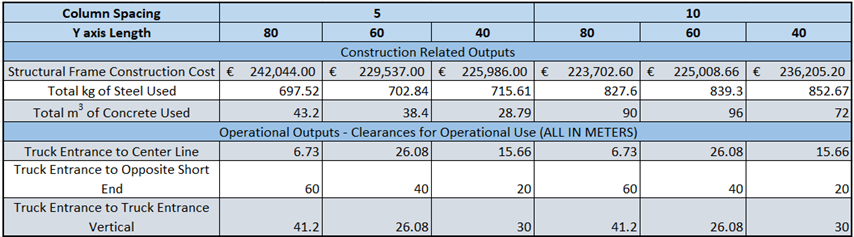

Then using the model, and a separate coding, the total cost for each layout is calculated. Other outputs such as the weight of steel, total concrete used, and operational parameters that describe the storage area represented in Table 2 below, are to be discussed in the next section.

Fig. 6 Design Outputs for each Layout Option

Discussions and Conclusion

1. Discussion of the Different Design Options

The model provides a tool for stakeholders to evaluate multiple criteria for the design. It demonstrates that structural frame costs are minimally affected by column spacing changes due to the trade-off between material costs and labor savings. For example, increasing column spacing from 5 meters to 10 meters results in larger structural sections and foundations but reduces labor costs by halving the number of bays. A similar trend is observed when comparing 80m x 20m and 40m x 40m layouts with identical column spacing.

While increased bay numbers may use less material, they significantly raise labor costs due to more welding and steel erection. This creates an inverse relationship between eco-friendliness and labor costs. The 10-meter spacing reduces labor and construction time but requires considerably more material, particularly in the 80m x 20m layout, which achieves notable savings through reduced bays and labor. On the other hand, the 40×40 section is eco-friendly as it has considerably less concrete usage in both spacing options. Even though steel usage is higher, the environmental impact of concrete is significantly more harmful than steel, therefore this makes this more sustainable but the square shape is generally not selected for operational purposes.

In contrast, the 60m x 26.67m layout emerges as the most optimal option, balancing moderate-to-low material usage with significantly lower total costs. This layout’s structural efficiency makes it a compelling choice among the alternatives. The operational information that is in the second half of the table also shows a decent layout for the storage, which can be desired for the purposes of the building.

2. Discussion of the Parametric Model for the Future Work

Due to the size of this project, the construction cost, and the sustainability parameters are not drastically different from each other. However, this model provides significant insight and logic that can be developed for bigger projects where the difference is remarkable. To elaborate, the model showed us that in similar steel frame buildings, there is an inverse ratio between the ecological friendliness of the production and the labor cost. In a similar big-scale project, the difference between could be so high that a stakeholder may want a higher cost but less wasteful design.

Furthermore, we saw that saving in material costs does not always mean saving in labor costs for these types of structures. Better design can help reduce the environmental damage and material cost but the labor intensiveness does not diminish but increases. Especially nowadays where the hourly labor cost is spiking, this may lead some stakeholders, and decision-makers to select practical, fast schedule projects that are not very sustainable. This aspect of the model can be improved by implementing more accurate labor costs, the labor cost that is used in this model is an educated guess from a construction background.

This model can be enhanced with the input of the other design teams, such as operational, mechanical, electrical, and architectural. Different design options allow the decision makers to change the layout per the new information acquired during the design process, and to develop this model even further with their inputs on cost, sustainability, and other variables that are in high-performance criteria.

SketchFab Model

References

- Warehouse Layout Design Principles.” Logistics Bureau, 15 Nov. 2023, logisticsbureau.com/warehouse-layout-design-principles

- De Weck, Olivier L. “Multiobjective Optimization: History and Promise.” Proceedings of CJK-OSM3, 2004, Kanazawa. Massachusetts Institute of Technology. https://scholar.google.de/citations?view_op=view_citation&hl=de&user=GFEciiAAAAAJ&citation_for_view=GFEciiAAAAAJ:0EnyYjriUFMC

- Farias, Arthur Almeida Cordeiro de, et al. “Analysis and Design of Structural Elements of an Industrial Steel Warehouse with Overhead Crane.” International Journal of Engineering Research and Applications, vol. 12, no. 2, (2022).

- “Stahlpreisindex.” Stahl Kompakt, https://www.stahl-kompakt.de/SK.Premium/Stahlpreisindex.aspx. Accessed 8 Jan. 2025.

- Eurocode 0: European Committee for Standardization. EN 1990: Eurocode – Basis of Structural Design. December 2005, incorporating corrigenda December 2008 and April 2010.

- Eurocode 1: European Committee for Standardization. EN 1991-1-1: Eurocode 1: Actions on Structures – Part 1-1: General Actions – Densities, Self-weight, Imposed Loads for Buildings. April 2002, incorporating corrigendum March 2009.

- Eurocode 3: European Committee for Standardization. EN 1993-1-1: Eurocode 3: Design of Steel Structures – Part 1-1: General Rules and Rules for Buildings. May 2005, incorporating corrigenda February 2006 and March 2009.

- Eurocode 4: European Committee for Standardization. EN 1994-1-1: Eurocode 4: Design of Composite Steel and Concrete Structures – Part 1-1: General Rules and Rules for Buildings. December 2004, incorporating corrigendum April 2009.

- Eurocode 8: European Committee for Standardization. EN 1998-1: Eurocode 8: Design of Structures for Earthquake Resistance – Part 1: General Rules, Seismic Actions and Rules for Buildings. December 2004, incorporating corrigendum July 2009.

- Euronorm 53-62: Hot Rolled I-Sections – Dimensions and Weights. European Committee for Standardization, 1962.

- Euronorm 19: Rolled Steel I-Sections. EN 19-57. 1957. European Committee for Standardization.

- DIN 1026-1: Hot Rolled Channels – Dimensions, Masses and Static Parameters. DIN 1026-1. 2000. Deutsches Institut für Normung (DIN)

- BS EN 10056-1: Structural Steel Equal and Unequal Leg Angles – Dimensions. BS EN 10056-1. 2017. British Standards Institution (BSI)