Nowadays, nearly any construction system, such as an Airport Hanger is built with a bottom plate which fulfills fundamental tasks such as passing the weight of the structure evenly to the ground. This prevents irregular floor deformations, which could cause cracks in the structure. In addition to the load transfer, the bottom plate serves to protect the construction system which is built on it from the earth’s own movements.

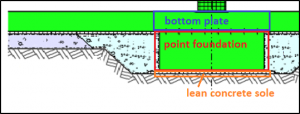

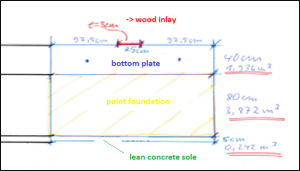

If you now look at a specific section of the bottom plate, it becomes clear, which elements belong to it even the plate itself consists only of reinforced concrete. The combination of the three different layers forms the basis of the chosen system, which is shown in Figure 1.

Wherever large loads occur at certain points, for example as under steel frames of an airport hanger, so-called point foundations are necessary to avoid static overload of the substructure at these points.

By thinking of how to build foundations, there are three main design options, which also can be build differently:

- Point foundation

- Strip foundation

- Foundation plates

Here we will only focus on a subsystem of the bottom plate, the already mentioned point foundation. For the description of the point foundation three design parameter have been choosen in order to describe the system and are described in Part 1.2.

In addition to the parameters, two different designs were chosen. These differ mainly from the dimension and type of manufacture of the foundation. The figure below shows the principle based on one of the possible design options.

In order to make the maintenance of a construction system economical and effective over the entire life cycle, it is important to take possible risks and errors into acount already in the design phase. This is particularly relevant in the composition of several subsystems, as these can influence each other in several points. One of the most important points here ist the maintenance, which is required in order to avoid failure of the entire or partial system.

For the maintenance of the shown system, following steps were defined:

- Esthetic maintenance concrete bottom plate (EMC)

- Inspection measurement (IM) to prove the status of point foundation

- Concrete maintenance point foundation via injection (CMF)

- Replacement deck layer – conrete bottom plate (RCBP)

- Replacement concrete foundation (RCF)

It should be noted that maintenance steps on bottom plates and their subsystems are generally less common since they are built for a long lifetime. However, you can prevent damage but not avoid it, which leads to the maintenance works. Aesthetic works, measurements and reinforcement measures such as injections occur over the lifetime of individual parts of the system, such as point foundations. However, a complete new casting of the bottom plate or an exchange of the complete foundation is rather the exception. If you compare the structure to that of an air strip, it becomes clear that not every structure needs the same maintenance. Regular maintenance for the air strips are fundamental to guarantee safety.

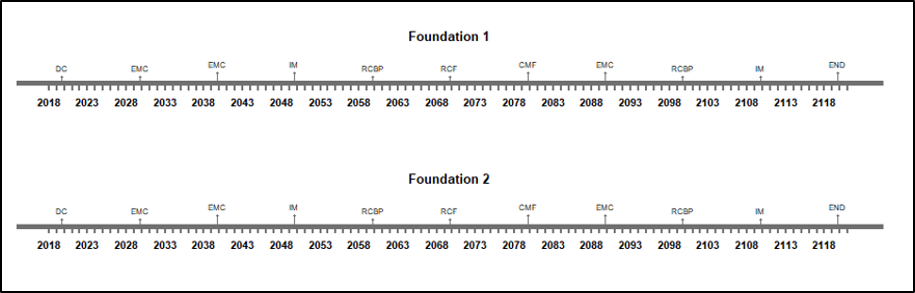

Figure 3 shows the maintenance timeline when all maintenance actions are executed as much as possible.

It can be seen that the different dimensions of the point foundations and the type of manufacture (prefabricated or cast in place) don’t lead to any differences in the maintenance intervals.