Explanation of System:

Offshore wind turbines are wind power generators that are placed in bodies of water, such as the ocean or a lake, rather than on land. These turbines are designed to capture the stronger and more consistent winds found in offshore environments, converting the kinetic energy of the wind into electrical energy. The turbines typically have large rotors and tower-like structures that are anchored to the seabed using foundations such as monopiles, jackets, or gravity-based systems.

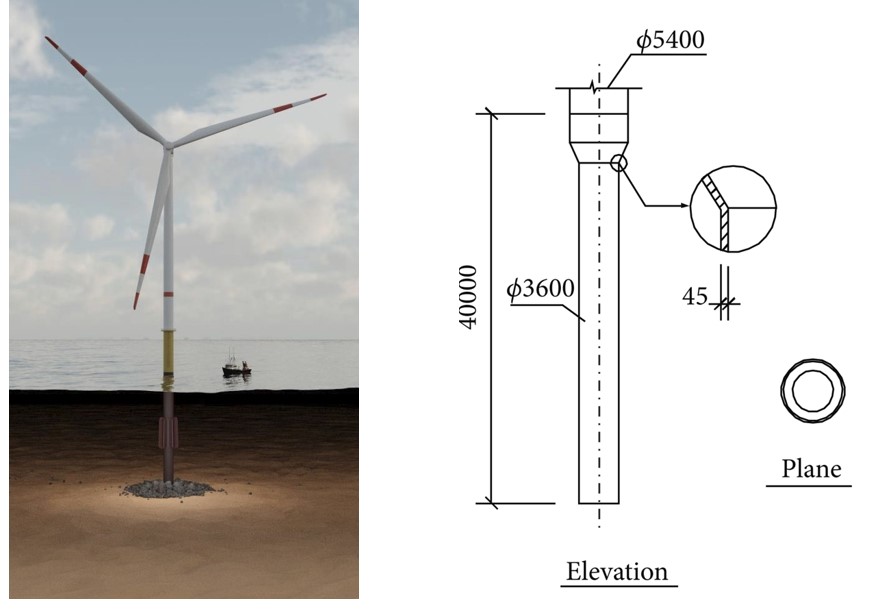

Dimensions of the system:

The monopile foundation is a critical component of the offshore wind turbine system. It represents the largest volume of the system material and is made of high-strength steel coated in epoxy to protect against corrosion. The cylindrical shape provides stability and helps resist bending and torsion, ensuring a strong foundation for the wind turbine, depicted in Figure 2. The assumed dimensions (length of 45 m, diameter of 6 m, thickness of 0,2 m) were determined based on research and data analysis. [2] [4]

- 654,9 t of steel

- 0,15 t of epoxy

The assumed emissions for the production are:

- 197,76 t of CO2

- 0,106 t of SO2

- 5,74 t of NOx

- 276748,74 MJ of Energy

Maintenance:

As the structural integrity of the monopile foundation is a highly important aspect of an operating wind turbine, the following maintenance actions are necessary [5]:

- Inspections: Regular inspections are crucial to the maintenance of the monopile substructure. This involves checking for signs of corrosion, cracks, or other damage that may affect the integrity of the structure.

- Painting and Coating: The monopile foundation must be regularly painted and coated to maintain its resistance against corrosion. This can be done through the use of anti-corrosion coatings and touch-up painting to address any areas of corrosion.

- Cleaning and Debris Removal: It is important to regularly clean the monopile and remove any debris that may have accumulated on it. This will help to prevent the build-up of marine growth, which can impact the structure’s performance.

- Scour Protection Monitoring: Scour protection is a crucial aspect of the maintenance of the monopile substructure. Regular monitoring of the scour protection measures, such as rock placement or geotextile fabric, is necessary to ensure that the foundation remains stable and protected against erosion.

For the considered lifetime of 25–30 years, the following maintenance intervals are fixed as follows:

- Inspections and change of sacrificial cathodic protection every 2–7 years

- Cleaning and repair of scouring protection every 5 years

- Complete renewal every 30 years

References: