In this scenario the tunnel crosses a river that flows into the sea after it has been retained by a dam. It acts both as an infrastructure building and as a conduit for other media such as water and electricity. For traffic, besides the dam, the tunnel provides one of two alternatives to cross the river in the case of the water, the processed fresh water from the Reverse Osmosis Plant is meant, which is transported to the other side of the river.

two alternatives to cross the river in the case of the water, the processed fresh water from the Reverse Osmosis Plant is meant, which is transported to the other side of the river.

The tunnel for this special scenario is simplified to its general embodiment of a load bearing, reinforced concrete tube. It was excavated with the help of a tunnel drilling machine and build according to the “New Austrian Tunneling Method” (NÖT). This method uses steel reinforcements as well as 2 layers of concrete (jetcrete and site concrete). For the Life Cycle Analysis (LCA), the construction method is of secondary importance, since all conventional tunnels use a combination of concrete and reinforcing steel and therefore have similar damage patterns.

Although the pipes for water transportation and the need for electricity to operate the tunnel are considered in this scenario, they are not considered in more detail. This also applies to other elements such as support-pillars, carriageways, ventilation, security systems and entrances. The shutdown of the tunnel means the water from the reverse osmosis plant must be transported through the dam and traffic has to be redirected to the dam. This means simultaneous maintenance work on the tunnel and dam must be avoided at all costs. The other two systems are not influenced by tunnel maintenance and can be maintained simultaneously.

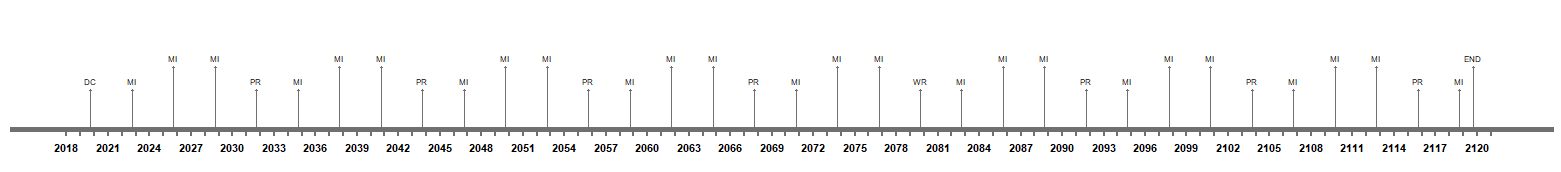

For this LCA, the tunnel will undergo different maintenance events, which will shut down the tunnel and prevent any use. This also includes the transport of water through the pipes for safety reasons. Those events range from small repairs to partial reconstructions to complete reconstructions / overhauls of the tunnel.

Maintenance Inspection (MI)

The Maintenance Inspection is done regularly every 3 years, including visual investigation of the tunnel structure as well as small repairs. This includes inspection of the driveway and water pipe and causes the whole tunnel to shut down for safety reasons. Just considering the inspection cost, this maintenance costs 3.540€ on average, ignoring any other costs caused by the downtime.

Partial Reconstruction (PR)

While the Partial Reconstruction are not mandatory, literature indicates that tunnels in Germany undergo regular repairs every 15 years that can be considered as partial reconstructions. In case of the considered tunnel, this maintenance causes the whole tunnel to shut down for 30 days and costs on average 1.260.000€. This is due to major damages in concrete which make medium-sized projects necessary.

Whole Reconstruction (WR)

Reaching a third of its total planned lifetime, on average a tunnel needs more than partial reconstructions. In most cases the whole tunnel structure undergoes a complete overhaul. That does not mean, the tunnel is reconstructed but the efforts to overhaul a tunnel are huge. Strongly depending on tunnel size, length and building method costs can fluctuate greatly. While the tunnel is closed for one year, the reconstruction costs 13.210.000€.

The used information and values were taken from various sources such as or estimated if no clear information could be found. The differences in downtime and costs for those maintenance events are displayed in detail here[LINK].

Figure Sources:

Figure 1: https://de.wikipedia.org/wiki/T%C3%BCbbing#/media/Datei:Tuebbings_CTL.jpg

Figure 2: https://www.stuva.de/downloads/publikationen/pdf/STUVA-Sachstandsbericht_2017_web.pdf

Figure 3: Timeline-Plot for tunnel maintenance strategies from R