1. Introduction

As temperatures around the globe rise, and in-depth studies reveal how much standard building materials contribute to that warming effect, engineers and designers must look more into alternative options. Newer manufacturing techniques allow us to form innovative materials such as structural lumber – but how much do these alternatives contribute to emissions?

In this Life Cycle Analysis (LCA) study, we explore three different types of mass-timber beams commonly used in residential or light commercial buildings. The energy consumed and emissions produced in the lifetime of each beam type are assessed and ranked by importance, resulting in a comparative analysis of their associated carbon footprints. (The references are given in the Full Report at the end of the page.)

2. Goal and Scope

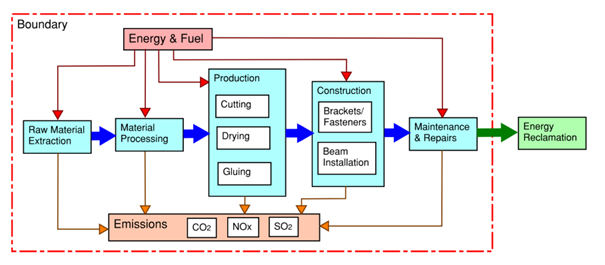

This analysis is based on mass-timber beams found in timber-framed residential buildings, with the goal of comparing the carbon footprints of Laminated Veneer Lumber (LVL), Glue Laminated Timber (GLT), and Cross Laminated Timber (CLT). The boundaries of the system analysis are depicted below:

The energy required for wood harvesting, initial processing, beam production, construction, and beam maintenance will be quantified, as well as the emissions from those lifecycle stages. Due to time constraints and limited data sources, the potential energy reclamation often associated with wood products will be excluded.

3. Design Options

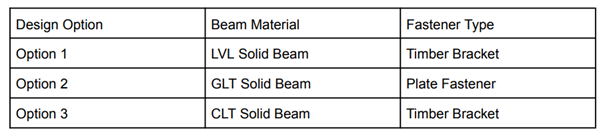

Each beam type has a different configuration of wood components, resulting in various types of cross sections. Cross-Laminated Timber (CLT) is composed of wood studs oriented so that the grain of each layer is perpendicular to that of the neighboring layers. By contrast, the wood grain of each Glue Laminated Timber (GLT) layer faces the same direction throughout the beam. The final beam type, Laminated Veneer Lumber, is composed of many layers of thin wood veneers, typically about 3-5mm thick. For our study, we will analyze the following three design options:

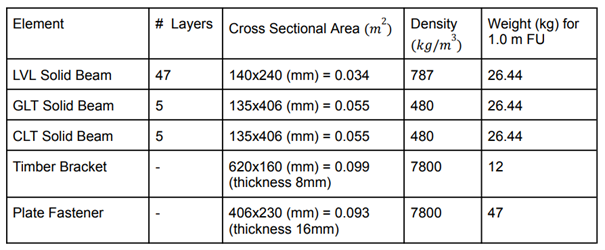

We define the materials as shown in the table below. All beam types are assumed to be hardwood, fully-edge glued, and placed under typical loading patterns for a residential building. The functional unit is a 1 meter long beam span. Assume for the GLT and CLT beams that each layer is ⅕ th of the cross-section width (Balasbaneh, A. Sher, W.), and for the LVL beam that veneers are 3mm layered lengthwise (Lu, H.). The fastener cross sections are calculated as if folded flat, with two plates on either side and one set of fasteners for each end of the beams. Bolts and screw weights are included.

4. Life Cycle Inventory

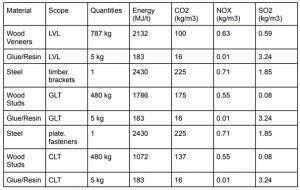

At the end of the beam’s lifetime, we can total the amount of energy and emissions used in the process for each material component. For this report, we will analyze the embodied energy, the amount of 𝐶𝑂2 , and emissions. The wood studs used for both GLT and CLT 𝑁𝑂𝑥 𝑆𝑂2 were deemed comparable (Demirovic, E.), although from one study we find that the overall production of CLT studs use 40% less Energy than GLT, and 22% less 𝐶𝑂2 than GLT (Balasbaneh, A. Sher, W.). The LVL veneers are assumed to be 3mm (Puettmann, M.).

5. Life Cycle Timeline

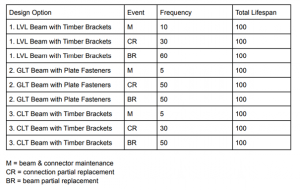

The lifespan of a typical timber-framed residential building is around 100 years, as confirmed in multiple sources and the Fault-Tree project associated with this report. During this lifetime, there are several maintenance and repair events that a beam system may need to undergo. We assume that GLT and CLT beams are similar enough to require the same frequency of beam-specific maintenance, and that the thicker bolts used in the plate fasteners are more durable than the threaded screws in the timber brackets. The interventions are summarized in the following table:

6. Life Cycle Analysis

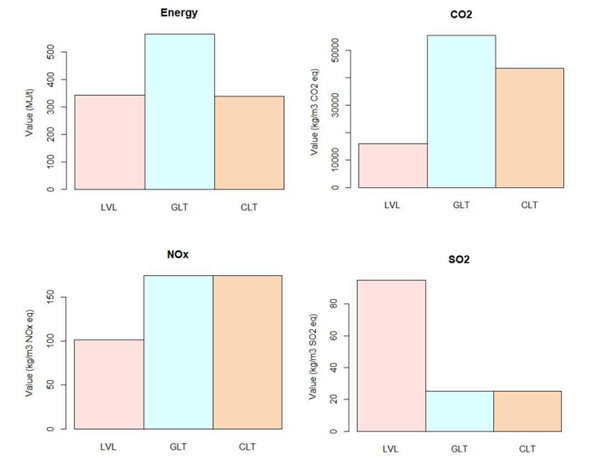

We can now sum the energy and emissions consumed in the processing, machining, construction and maintenance for each beam design option. We use a beam length of 6 meters, for a representative residential housing span. The volume of materials is calculated for all beam and fastener combinations, and a matrix is created of quantities and intervention values for all three options.

From the graphs above, it is obvious that GLT consumes more energy and 𝐶𝑂2 than the other beam options, and that the LVL design option performs the best in most categories besides 𝑆𝑂2 emissions. That being said, it can be difficult to visually compare them in a way that allows a designer to make a confident choice in beam selection. It is therefore imperative that we conduct a multi-criteria decision analysis to select the best design option.

7. MCDM – Analytic hierarchy process (AHP)

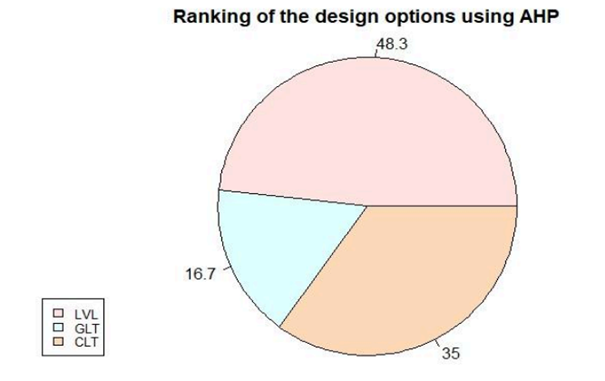

In this criteria analysis, different weights were assigned to the design options – both within the energy and emission categories, and to those larger four categories themselves. In general, the lowest value column was favored highly, and equally valued columns were set to equal importance for simplicity. The 𝐶𝑂2 category was given the highest priority, as our main goal was to analyze the carbon footprint of each beam. Energy was given the next highest priority. Similar to 𝐶𝑂2 emissions, including end-of-life would allow for incorporating energy recovery from burning wood waste and other such methods.

However, the values used in this project were from non-renewable sources so we therefore want to minimize the amount of these sources used as much as possible. The final two emissions were given similar importance levels, with 𝑆𝑂2 slightly lower as a larger portion of the contributions may have come from the steel. The overall results are displayed in the pie chart below.

The AHP analysis confirms our suspicions from the bar charts, that the LVL design option is the favorable one. That being said, it must be noted that LVL had dramatically higher 𝑆𝑂2 emissions than the other three options. In our ranking system, was the least important 𝑆𝑂2 emission so this outcome makes sense, but this proves that no single material can ever be perfect.

To conclude, while in this study Laminated Veneer Lumber was chosen as the best design option due to its lower carbon footprint, another type of mass-timber beam might perform better under different goals. Analyses must therefore be extremely focused and clear when collecting data and reporting results, especially when using multi-criteria decision making such as the AHP method.

Downloadable Content

Full Report: Sofia Mari Wilkinson