Introduction

The airport pavement is a complex engineering design for the aircraft to land and take off with a high level of comfort. The passenger’s and aircraft’s comfort are the ultimate aims of the smooth runway pavement. There are three types of pavements: rigid pavement, flexible pavement, and composite pavement. The pavements are designed by estimating the total load on the road by taking aircraft size, frequency of flight, traffic volume, and geography of the place. In this model, we have considered them all except geographical aspects. Moderate traffic volume is assumed with the rigid pavement and flexible pavement. To achieve the intended design life and budget, appropriate slab thickness, subbase layers, and pavement surface material are considered here in four different design options, which can further be studied its life cycle assessment of every material in each layer of the pavement and analysis using R programming to select the best choice to build with fewer emissions.

Backround Research

As we have mentioned before, the airport pavement design is very complex. Aging is a terrible factor that plays in the airport pavement. The pavement deterioration process is a stochastic continuous change process due to data measurement errors, the non-linear behavior pavement deterioration process, and the role of unexplained influencing variables [1].

The main factor of runway deterioration is surface cracking. So, I decided to focus more on surface layer and layer just below it. As the repetition of load, frequency of take-off and landing occur the pavement’s surface get cracked. That means the surface cannot withstand that much load at that frequent.

Pavements of three flexural strengths and two different subgrades, a soft bituminous layer and a rigid layer, known as econocrete [2], are designed to reduce runway deterioration by preventing cracking. The degree of cracking decreased as the pavement’s flexural strength increased cracks formed over the econocrete base than over the bituminous base.

Pavements experiencing failure typically show signs of wear and tear by fragmenting or breaking away pieces of pavement; excessive longitudinal cracking extending several feet throughout the pavement. According to Li et al. (1996) [3], deterioration of a pavement is measured in pavement condition states (PCSs), each of which is ranked explicitly to a certain level according to pavement ride quality, roughness, structural adequacy, surface distresses, and safety.

Life-Cycle Analysis and Multi-Criteria Decision Making Analysis

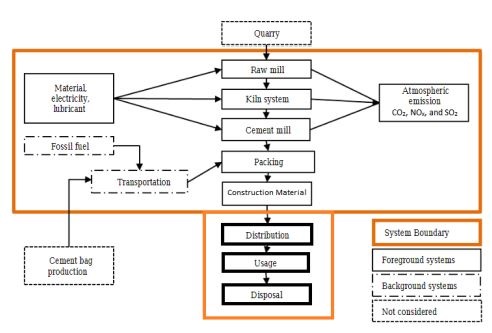

The system boundaries are presented in figure 2.3.1.

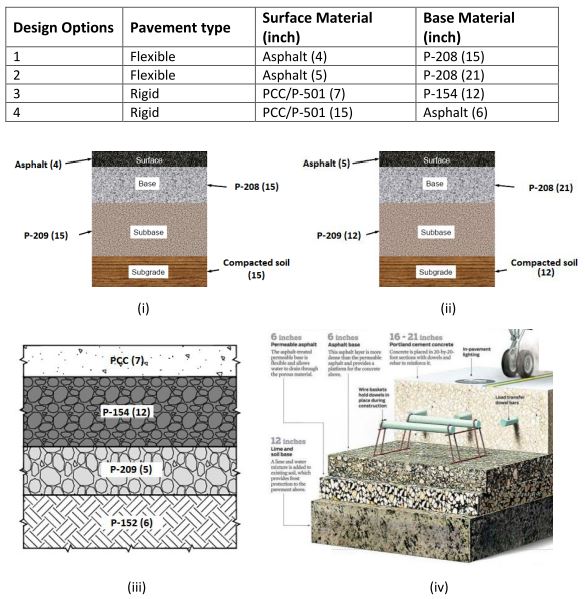

With that and the design options, shown in figure 2.3.2, it was possible to calculate the impact of each of the design alternatives.

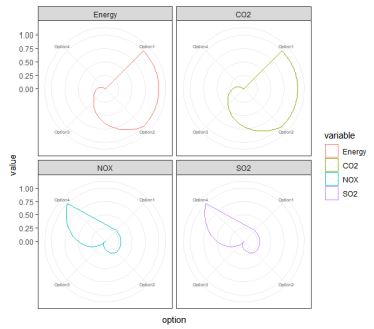

Which has be summed up in a radar plot as presented in figure 2.3.3 below.

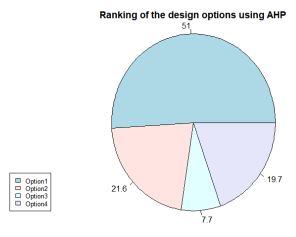

By adding weights to the furmulated criterias it was possible to rank the different design options, which is shown in figure 2.4.4.

References

[1] An Innovation of the Markov Probability Model for Predicting the Remaining Service Life of Civil Airport Rigid Pavements Baoli Wei 1,* , Chengchao Guo 2 and Miaoyi Deng 1

[2] Yusuf Mehta, Douglas Cleary, Ayman W. Ali, Field cracking performance of airfield rigid pavements, Journal of Traffic and Transportation Engineering (English Edition), Volume 4, Issue 4, 2017, Pages 380-387, ISSN 2095-7564, https://doi.org/10.1016/j.jtte.2017.05.010. (https://www.sciencedirect.com/science/article/pii/S2095756416302884)]

[3] Li, N., Xie, W., & Haas, R. (1996). Reability-based processing of Markov chains for modeling pavement network deterioration (Vol. 1524, pp. 203–2012). Washington, DC: Transportation Research Record