The nuclear power plant is located on the west coast of the Dithmerschen area of Schlweswig-Holstein on the banks of the lower Elbe. The plant generates 1185 MW of electricity for the Railway Power Supply System, Offshore Wind Farm, and the Vertical Lift Bridge.

Nuclear reactor

The differentiation between nuclear powerplants is based on the type of the super system, which is the nuclear reactor. The plant located in the city of Brunsbüttel operates using an advanced gas-cooled reactor.

Design

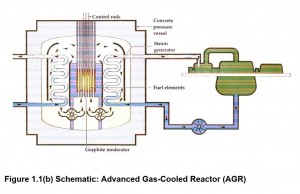

The main components of this reactor’s type, as displayed in the figure above, are as follows:

- Fuel rods (core)

- Thermal shielding

- Pressure vessel

- Concrete shielding

- Steam generator

- Feed Pump

- Turbine

- Generator

- Condenser

Due to the complexity of the superstructure with its many components, a major part of this structure had to be selected for life cycle analysis, which is the nuclear core.

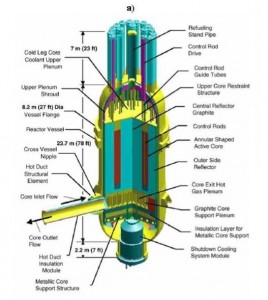

Geometry

Height: 23.7 m

Diameter: 4.8 m

Total Area: 18 m²

Number of fuel rods: around 332 rods

Materials

Throughout the life cycle analysis, three different design parameters were distinguished as important aspects in building maintenance strategies and eventually reliable optimization methods. These aspects are:

Moderator: The main material of this component is graphite. The function of graphite is to slow down the neutrons released during nuclear fission processes.

- Coolant: This part of the reactor is identified through the type of the used gas. Here, it is helium, which is a cooling gas that is widely famous for its easier containment and fewer energy wastefulness.

- Fuel: The main material used, as in any other nuclear reactor, is uranium. However, this uranium is low enriched (2.5-3.5 %) and normally assembled in stainless steel tubes.

Maintenance interventions

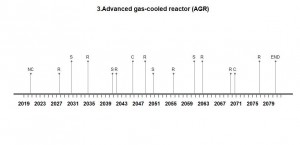

The typical maintenance scheme of advanced gas cooled reactor consists of different preventive and corrective maintenance activities. Capturing all these interventions in one scope could be quite challenging, especially for planned data fusion with four different civil systems (Wind Farm, Railway System, Lift bridge, and a Truss Bridge). Therefore, with a lifetime of 60 years, three major interventions were considered as follows:

- Replacement of major helium turbo compressor components (R)

Description: In-situ turbomachine maintenance will be performed during scheduled plant outages, when possible, because the reactor must be shut down and the PCRV (prestressed concrete reactor vessel) depressurized before anyone can enter the vessel. The shielding requirements have been established to give a radiological environment in the turbomachine bearing cavity areas conducive to personal access.

Intervals per years: Every 7 years

Duration: 10 days

Start date: 15.11

- Steam generator inspection (S)

Description: Inspection process happens mainly in tubes of the steam generator. These processes are critical to the safe and economical operation of nuclear power plants. Often, different characteristics of the damage (corrosion, cracking, fatigue, etc.) require different types of inspection tools. A shutdown of the plant depends on the severity of the damage happening in or outside these tubes. For example, a detectable leakage of tubes exceeding 10 kg/h would require a shutdown until corrective measures take place.

Intervals per years: every 10 years

Duration: 5 days

Start date: 15.05

- Core testing (C)

Description: These interventions occur relatively rarely since the reactor’s core is constantly monitored and data is being transmitted throughout important nuclear activities (refueling). In other words, core inspection or testing is a predefined maintenance activity that includes a remote checkup on the graphite bricks of the core. This procedure is carried out using cameras and robotic materials in order to avoid radiation exposure. It ensures the integrity of the graphite structure where potential cracking is pound to occur due to frequent nuclear fission processes and oxidation. A complete shutdown is planned for such activity.

Intervals per years: every 25 years

Duration: 40 days

Start date: 30.05

REFRENCES:

- Haque, Nawshad; Norgate, Terry; Tharumarajah, Rajah; Koltun, Paul (2011): Life cycle assessment

of the uranium nuclear power cycle – Part 2a: New generation GT-MHR power plant with once

through technology. - Parisot, Jean-François (2006): Gas-cooled nuclear reactors. Paris: Commissarita a l’energie

atomique. - General atomics, Gas Turbine-Modular Helium Reactor (GT-MHR), Conceptual Design Description Report, July 1996.

- Bonivento, Claudio; Grimble, Michael J.; Giovanini, Leonardo; Monari, Mattia; Paoli, Andrea (2008): Monitoring a gas-cooled nuclear reactor core integrity. In IFAC Proceedings Volumes 41 (2), pp. 12953–12958. DOI: 10.3182/20080706-5-KR-1001.02190.

- https://www.world-nuclear.org/information-library/nuclear-fuel-cycle/nuclear-power-

reactors/advanced-nuclear-power-reactors.aspx