Abstract

Energetic retrofit solutions for the existing building stock will get more important in the next few years. To give a first support for the design process of a facade panel, this study is about creating a parametric model based on the ontology developed in the further project. It has been aimed to have strong control about the design parameters to give diverse alternatives with different results. To evaluate the model, two high performance criteria are defined: a low heat transfer coefficient U to contain the loss of energy and a weight of the element mges designed to be as low as possible. According to the selected high performance criteria the results are shown and compared.

1. Scope and high performance criteria

According to the ontology-prefabricated-fasade, this study is about the development of a parametric design model of a prefabricated façade panel for the energetical retrofit of an old apartment building placed in Germany. For the retrofit solution the focus of the parametric model is on the dimensioning of the new, prefabricated façade panel. The facade panel is timber based with adaptive insulation layer, inner and outer paneling as well as timber frame and inner insulation – like explained in [1]. The materials used are XPS 035 insulation [6], OSB/3 [7], finger joint solid construction timber [8], STEICOflex 036 insulation [9] and cement bonded particleboard [10]. Of course if the materials are changed, the results will differ.

An important factor for this is to enhance the heat transfer coefficient U, defined as the “heat flow rate divided by temperature difference between two environments” [2]. Because of the importance of this influence factor, it is chosen as the first high performance criterion. The second high performance criterion is the total mass of the facade. Existing buildings mostly have poor masonry or concrete walls, where the panel has to be anchored. The facade has to be as light as possible.

Figure 1: high performance criteria

Figure 1: high performance criteria

2. Developing a parametric model

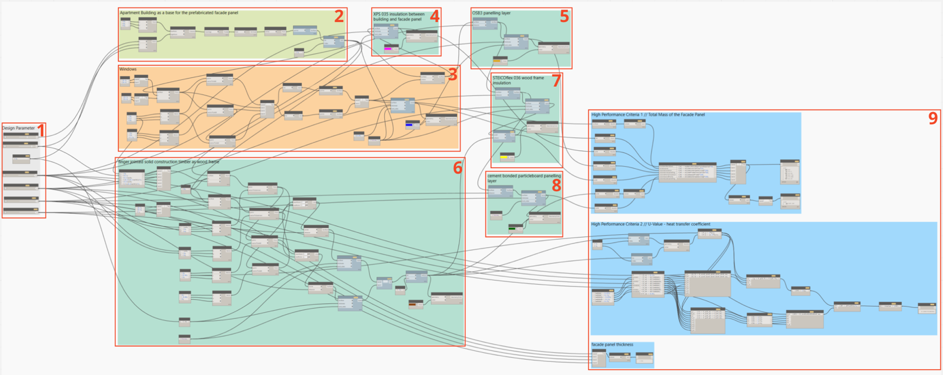

For the development of the parametric-model-prefabricated-facade Dynamo Revit 2.10 had been used. The workflow is shown in Figure 1. In the first part, the design parameters were summarized. Steps 2-8 show the creation of a simple building and the implementation of the prefabricated facade element. Starting from the building block, the façade element was created layer by layer – starting with the additional insulation layer, continuing with the planking and the timber frame construction with inner insulation layer. The suggestion of two windows were also included in the façade module.

Since the different thicknesses of the individual layers are decisive for the results of the high performance criteria, it is important to always have good control over the changes. That’s why every input parameter is placed in Part 1. The total thickness of the façade structure as well as the two high performance criteria U and mges were calculated completely in Dynamo. If one of the design parameters is changed, the results also change.

3. Results and Discussion

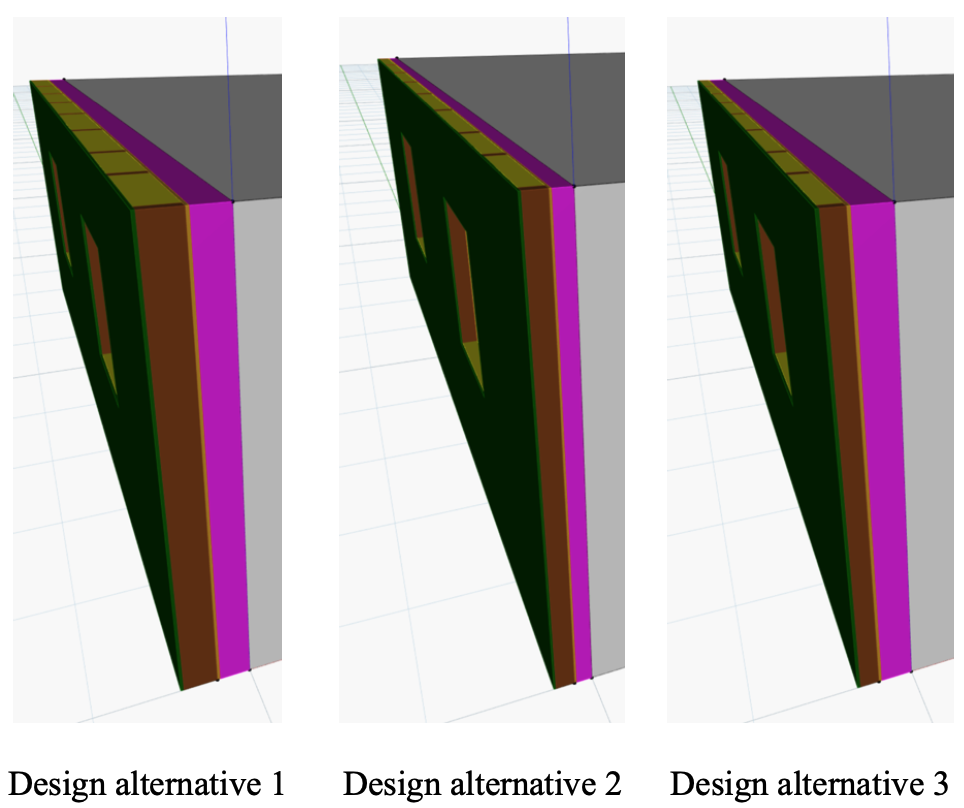

The three design alternatives are shown in Figure 3. The first option shows the strongest wall construction with 0.456 m, divided into 0.20 m adaptive insulation, 0.018 m OSB/3, 0.22 m wood frame and 0.018 m cement bonded particleboard. Due to the two large insulation levels, U = 0.12 W/(m2K) is the best compared to the other options. Because of the high thickness, the option 1 shows a total mass of mges = 1184.30 kg. As a counterpart, alternative 2 shows the lowest thickness with 0.244 m, which is divided into 0.10 m adaptive insulation, 0.012 mOSB/3, 0.12 m wood frame and 0.012 m cement board. Due to the very narrow wall construction and the resulting low insulation thickness, the heat transfer coefficient is U = 0.23 W/(m2K), which is above the limit value (0.20 W/(m2K)) for subsidized energy-efficient refurbishment in Germany, which was mentioned in Chapter 1. Compared to option 1, only the thickness of the additional insulation layer was reduced to the minimum, all other layers remain at their maximum thickness – which means 0.10 m adaptive insulation, 0.018 m OSB/3, 0.22 m wood frame and 0.018 m cement bonded particleboard. Although this means that the total wall thickness remains at a relatively high value of 0.356 m. As result of that the total mass mges = 996.38 kg is higher than option 2, but lower than option 1. Despite the reduction of the first insulation layer, the value of the heat transfer coefficient U = 0.13 W/(m2K) remains close to option 1.

Since this is an energy-related renovation measure, where the high performance criteria are aimed at a low U and a low mges , design alternative 3 is the best option out of this three options.

Download the Dynamo file: parametric-model-prefabricated-facade

References:

[1] Theis, Marlon. Project Assignment 1 – Prefabricated Facade Panel Ontological Modeling. 2022.

[2] Deb, C. Gelder, L.V., Spiekman, M. Pandraud, G. Jack, R., Fitton, R. Measuring the heat transfer coefficient (HTC) in buildings: A stakeholder’s survey. 2021.

[3] (online) https://www.uni-kassel.de/fb6/bpy/de/forschung/veroeffentlichungen/Publikationen00/Hoettges_UWert6946.pdf (retrieved on 10.01.2023)

[4] (online) Gesetz zur Einsparung von Energie und zur Nutzung erneuerbarer Energien zur Wärme- und Kälteerzeugung in Gebäuden (Gebäudeenergiegesetz – GEG). 2020. (retrieved from https://www.gesetze-im-internet.de/geg/GEG.pdf)

[5] (online) https://www.kfw.de/PDF/Download-Center/Förderprogramme-(Inlandsförderung)/PDF-Dokumente/6000003465_M_153_EEB_TMA_2018_04.pdf (retrieved on 10.01.2023)

[6] (online) https://www.ursa.de/de-de/produkte/Documents/DB-xps.pdf (retrieved on 10.01.2023)

[7] (online) https://www.dataholz.eu/fileadmin/dataholz/media/baustoffe/Datenblaetter_en/osb_en_01.pdf (retrieved on 10.01.2023)

[8] (online) https://www.dataholz.eu/fileadmin/dataholz/media/baustoffe/Datenblaetter_en/kvh_en_01.pdf (retrieved on 10.01.2023)

[9] (online) https://www.steico.com/fileadmin/user_upload/importer/downloads/produktinformationen_holzfaser-dmmstoffe/STEICOflex_036_en_i.pdf (retrieved on 10.01.2023)

[10] (online) https://www.dataholz.eu/fileadmin/dataholz/media/baustoffe/Datenblaetter_en/spz_en_01.pdf (retrieved from 10.01.2023)

[11] Bridge Tutorial. Parametric model generation with Dynamo. 2022.

[12] DiRoots. Dynamo Basic Training. 2018. (retrieved from https://www.youtube.com/@DiRootsNews)

Go to the Ontological Modelling here:

Prefabricated Facade Panel: Ontological Modelling

Combined System:

Sports Facility Center: Combined Parametric Modelling