Explanation:

Beams are used for structural configuration for several construction domains ranging from buildings to infrastructure. The ability of beams to bear flexural and shear loads, makes it a vital member of a structure. In buildings, beams take up the loads on the floor and transfer it to the other structural member which are usually columns, drop panels or primary beams. Because of their load bearing capacity, they increase the span between column strips. [1]

Fig 1 : A typical Concrete Beam

Retaining walls or cut off walls with addition of beams strengthen the walls to resist dead loads such as soil and rock debris especially in uneven elevations. [2]

Concrete Beam:

Beams are of several types which are distinguished based on their shape, size and material constituent. Materials used for constructing beams are reinforced concrete, steel, composite and timber. For our pipeline project, we are focusing on concrete beams as they can be easily integrated with retaining walls and cut off walls and support pipelines in uneven geography. Designs of concrete beams can be flexible based on the spaces in site and the durability of concrete in extreme climates and conditions is high. [3]

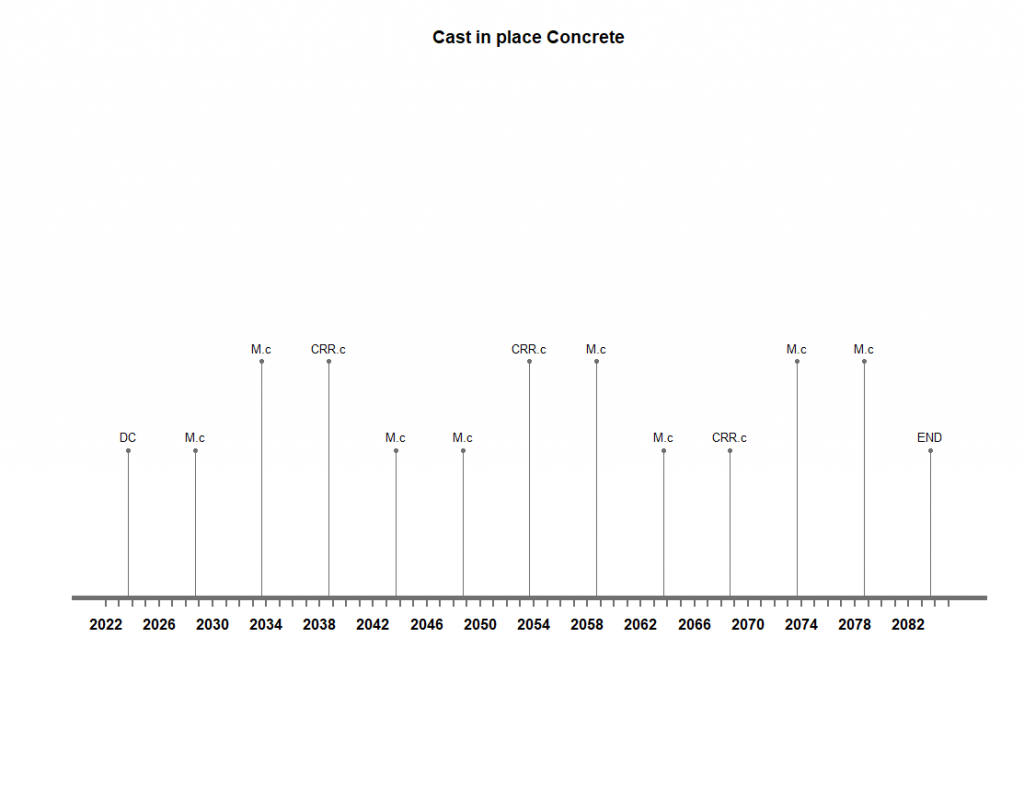

For the analysis of this sub-system of our project, three different design option of concrete beams were considered. The variables of these beams were the dimensions of the beam and the compressive strength of the concrete beam. For the steel design, structural analysis of the beams were carried out on CSI ETABS under ACI code A318-18. A simply supported beam with one end fixed and the other end pinned were considered. A uniform live load of 10 KN/m and a uniform dead load of 20 KN/m was applied on the beam for the design analysis.

Fig 2 : Shows a uniform live load applied on the beam

The details of the three mix design is shown below.

|

Element |

Cross Section Area (m2) | Compressive Strength Concrete (MPa) | Tensile Strength Steel | Area of Steel (%) |

| Mix Design 1 | 0.21 | 35 | Grade 60 | 0.68 |

| Mix Design 2 | 0.27 | 25 | Grade 60 | 0.6 |

| Mix Design 3 | 0.34 | 20 | Grade 60 |

0.65 |

Maintenance:

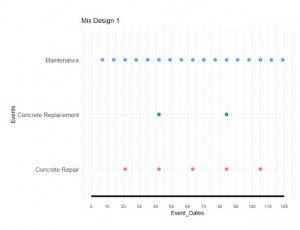

To prolong the lifespan of concrete elements like beam. Maintenance strategies have to implemented at scheduled intervals. Typical lifespan of a concrete beams extends to 120 years. There are several types of strategies that are either preventive or corrective measures depending on the type of maintenance required and structural health of a beam. Some strategies are cleaning, sealing, cracks repairing or re-applying concrete. [4]

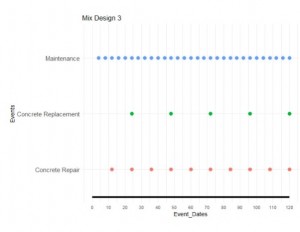

For this analysis, we have combined the categories to concrete repair, maintenance and concrete replacement based on the goal and result. The frequency of intervention is based on the concrete mix design. [5] The intervention schedule is shown below for the three design options.

Fig 3 : Mix Design 1 Fig 4 : Mix Design 2 Fig 5 : Mix Design 3

Fig 3 : Mix Design 1 Fig 4 : Mix Design 2 Fig 5 : Mix Design 3

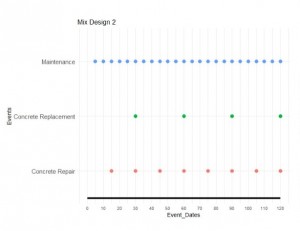

For the integration of the Concrete Beams into the whole system. The lifespan was considered till 60 years. The updated timeline is presented in the figure below.

Fig 6 : Updated Timeline for Concrete Beam

To learn more about the integration maintenance strategies of concrete beam into the whole system. Go to the maintenance planning page.

Life Cycle Analysis:

This analysis covered the carbon footprint of a beam throughout its lifetime. Its starts from the production of the raw material for concrete, transportation, construction and maintenance. To observe this, data was produced for emission of energy, CO2, NOx and SO2 as these are the main contributors affecting our environment by causing energy crisis, global warming, ozone depletion, toxicity, photo-oxidant formation, acidification and eutrophication. [6]

The highest consumption and emissions amongst the design options was for option 1. The quantities of every constituent of mix design is presented below.

| Materials | Scope | Quantities (Kg/m3) | Energy (MJ/m3) | CO2 (KG/m3) | NOX (KG/m3) | SO2 (KG/m3) |

| Cement | Mix Design 1 | 335 | 3.26 | 0.822 | 0.177 | 0.065 |

| Coarse Aggregates | Mix Design 1 | 1187 | 0.0035 | 0.016 | 0.0018 | 0.0018 |

| Fine Aggregates | Mix Design 1 | 712 | 0.0023 | 0.0053 | 0.009 | 0.009 |

| Reinforcement | Mix Design 1 | 53 | 2430 | 225 | 0.71 | 1.85 |

The total energy consumption and harmful gases emission for a beam of dimensions 0.3m width, 0.6m depth and 8m length were as follows:

- 200 MJ Energy

- 18000 KG CO2

- 150 KG NOx

- 210 KG SO2

References

[2] H Beam Steel for Retaining Walls

[3] Integrated Life Cycle Design and Assessment of Concrete Structures

[4] Maintenance of Concrete Structures

[5] Service life, reliability and their role in the life cycle analysis of concrete structures