INTRODUCTION

Acknowledging the rising rate of pavement construction and rehabilitation activities and the associated consumption of large material amounts, Optimizing the inferred environmental impacts is becoming a priority for the asset managers in order to adhere to the relative regulations and satisfy the sustainability requirements. As a result, the life cycle assessment approach is actually integrated at the design phase to ensure the adoption of the most advantageous pavement structure from the environmental perspective. As a starting point, we will identify the pavement subcomponent and their corresponding design alternatives that will undergo a comparative life cycle assessment analysis, then we will define the goal and scope of this analysis and the maintenance actions attributed to each design. Next, we will conduct a life cycle inventory, followed by a thorough life cycle cost analysis of the design options. Finally, we will implement a multi-criteria decision method to emphasizes the most convenient design option.

SYSTEM PRESENTATION

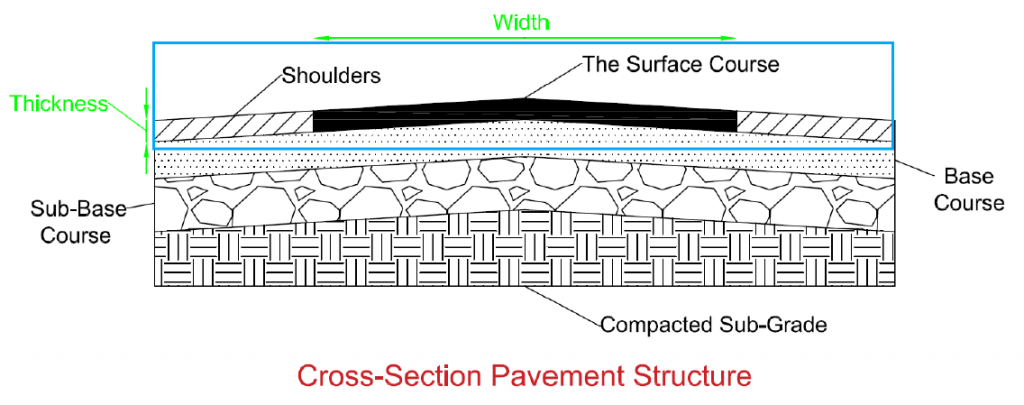

The pavement structure is composed of multiple layers that seek to carry out and transfer the vehicle loads to the subgrade foundation of the pavement, while remaining below its bearing capacity. In this context, the figure below displays the subdivision of these layers, which consists on the shoulders and surface course, the granular base course and the sub-base course. For the purpose of this project, it was elected to restrict the focus of our LCA approach on the shoulders and surface layer component, since it is subject to broad design variations, unlike other layers, especially in terms of materials usage.

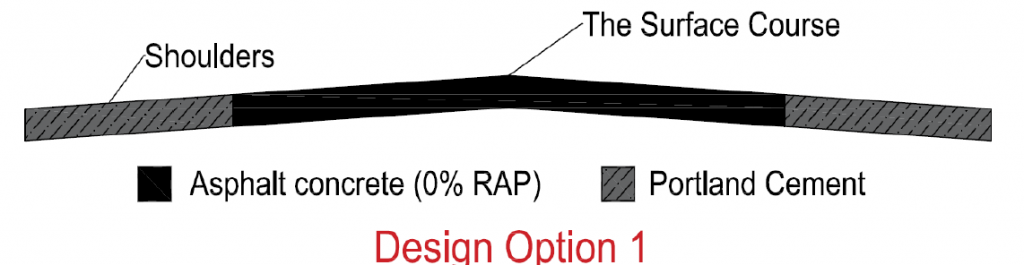

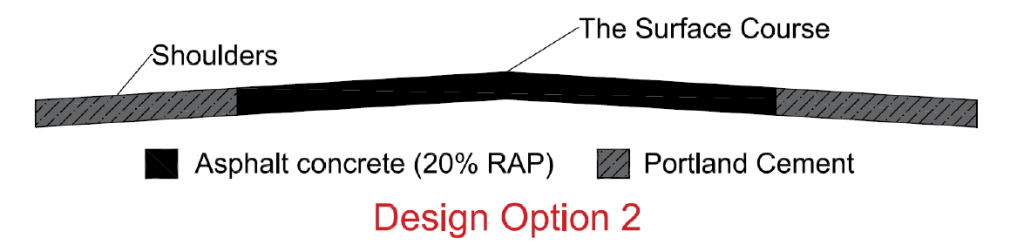

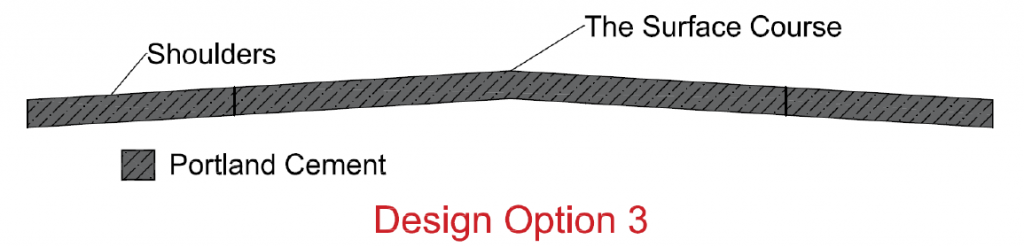

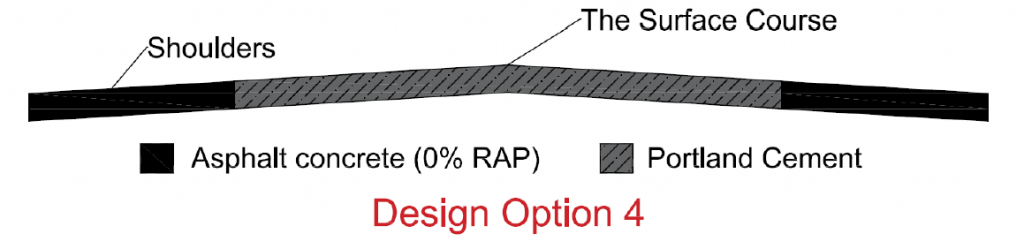

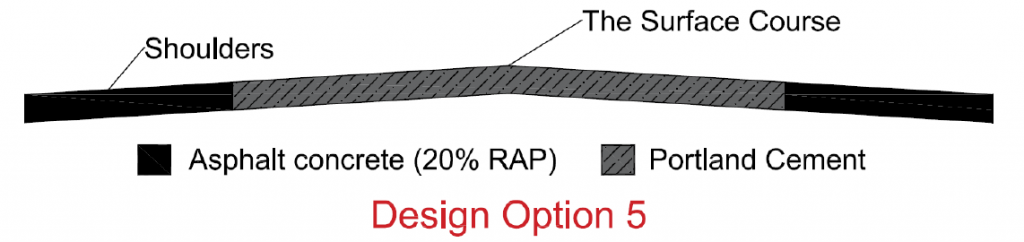

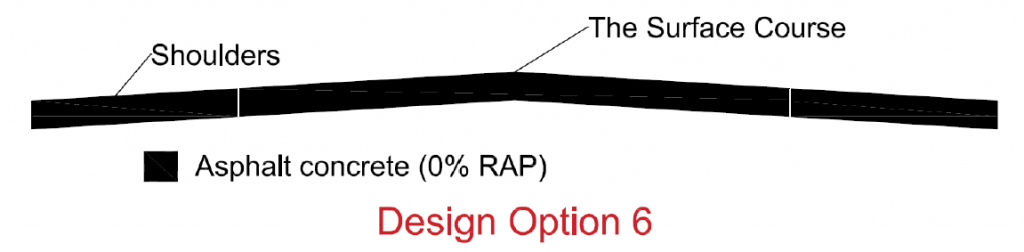

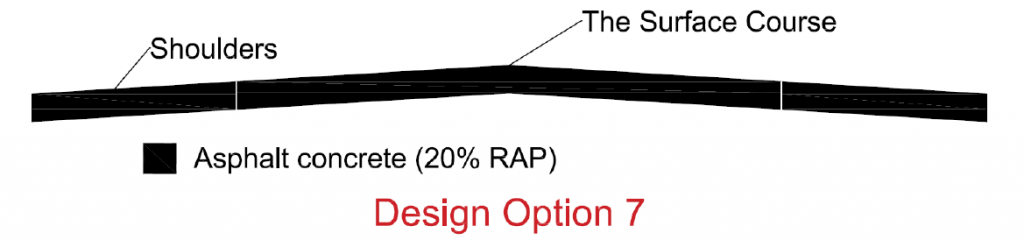

In the objective to alleviate the environmental burden of the component design concept, we attempted to generate a broad range of design options by varying the material types forming each part of the component between Portland cement concrete, new asphalt concrete and asphalt with 20% recycled asphalt pavement. by opting for different combinations of material types integrated respectively in the surface course and outer shoulders, we obtained 7 design alternatives as illustrated in the sketches below.

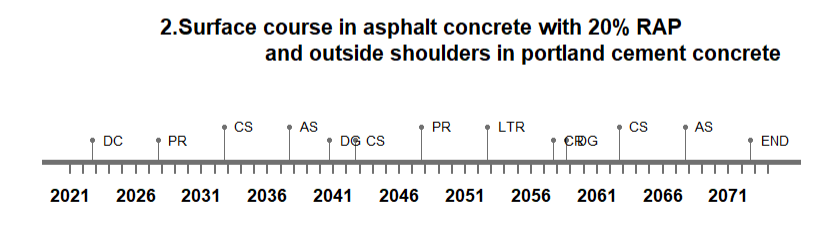

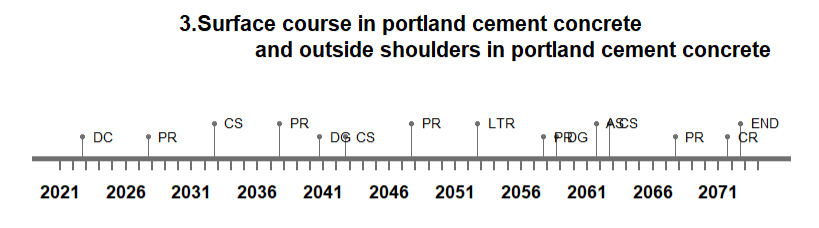

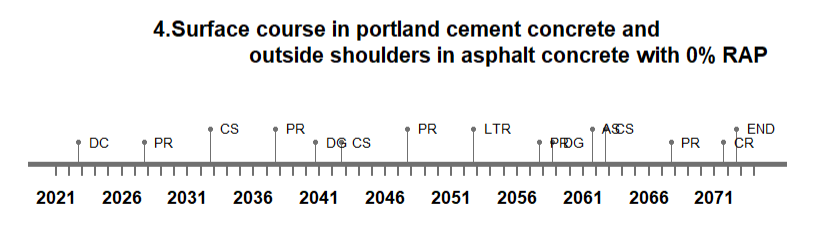

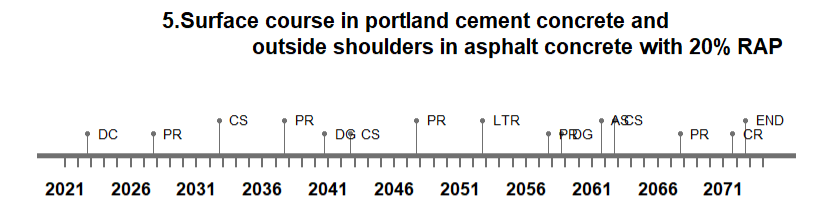

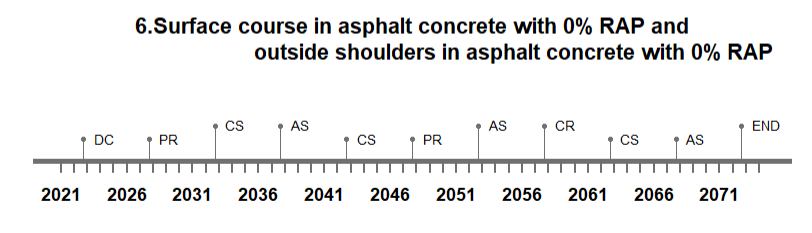

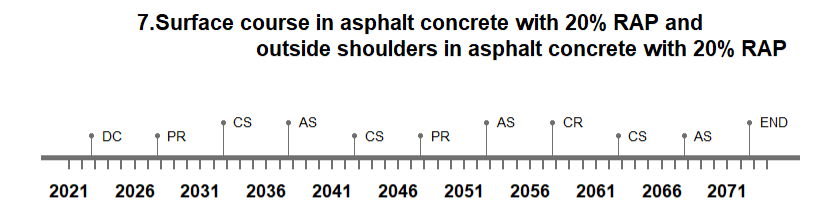

LIFE CYCLE TIMELINES

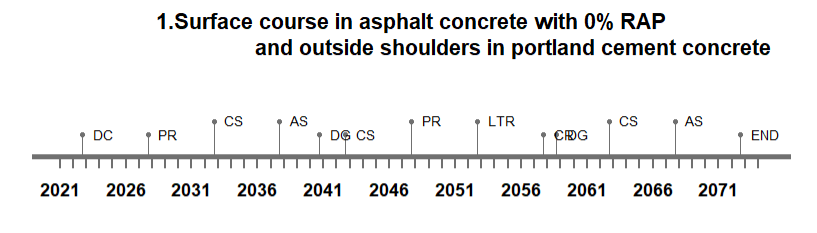

In parallel to the dimensional information provided by the Athena report, a detailed 50-year planning cycle was extracted from the report, which was established by the Quebec’s ministry of transportation to exhaustively specify the necessary maintenance and rehabilitation activities to perform on the pavement structure in a manner that covers its overall service life. However, the set of activities of the planning differs according to the type of material that forms the pavement, where the diamond grinding (DG), load transfer restoration (LTR) operations was assigned only for Portland cement concrete, whereas the crack sealing (CS), patch repairs (PR), asphalt overlay (AS) and complete replacement (CR) were shared by both types of pavement materials. By projecting these plannings on the predefined design alternatives and accounting for their material combinations, we managed to create the timelines of each design option, as illustrated in the figures below.

GOAL & SCOPE OF THE LIFE CYCLE ANALYSIS :

Based on the ISO guidelines, the Goal definition is the first step in conducting life cycle assessment. In this perspective, the goal of our study is to measure the energy consumption and the greenhouse gas emissions (GHG) of the pavement design alternatives highlighted above. The representative gas types comprise Carbone dioxide (CO2), Methane (CH4) and Nitrous Oxide (N2O). The functional unit is set up to two-lane kilometer of road pavement.

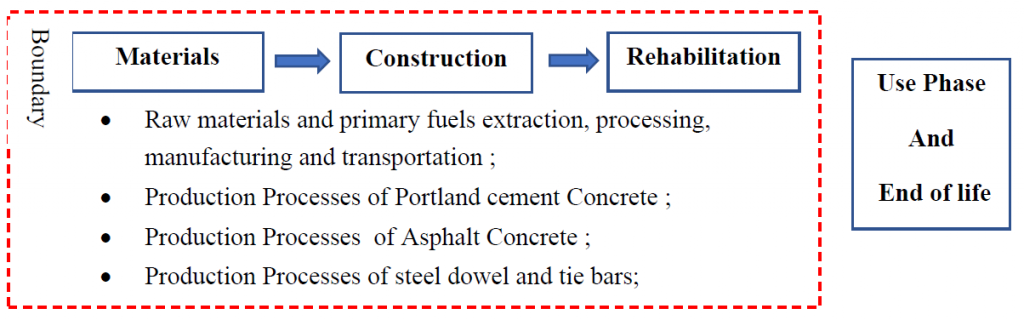

In the aim of accomplishing the life cycle inventory Analysis of the embodied energy and gas emissions related to the various conceptual designs, subject of our study, specifying the scope of our analysis with explicit details remains a crucial step to complete. Accordingly, the scope englobes the construction and rehabilitation phases, accompanied by their underlying material handling operations, as highlighted in the figure below.

LIFE CYCLE INVENTORY AND ANALYSIS

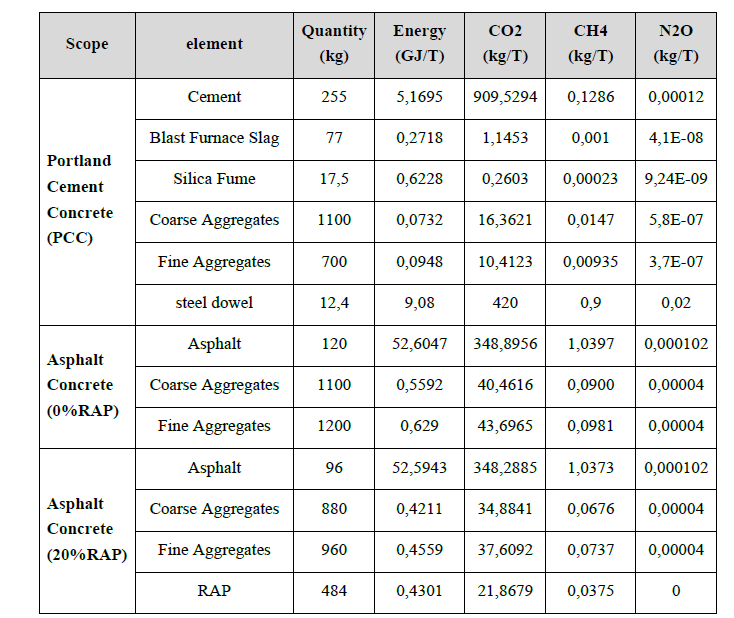

Recognizing the significant sensitivity of the LCA procedure to the underpinning life cycle inventory of each element that intervenes in the composition of the different materials shaping the design options, a critical attention was devoted to the establishment of these inventories. By skimming the domain literature (Wang et al 2016 & Athena Report), we gathered precise estimates about the primary energy (GJ/T) and the greenhouse emissions (Kg/T) associated with the production and delivery of 1m3 of each material, as showcased in the Table 2, while maintaining the compatibility with the analysis’s scope.

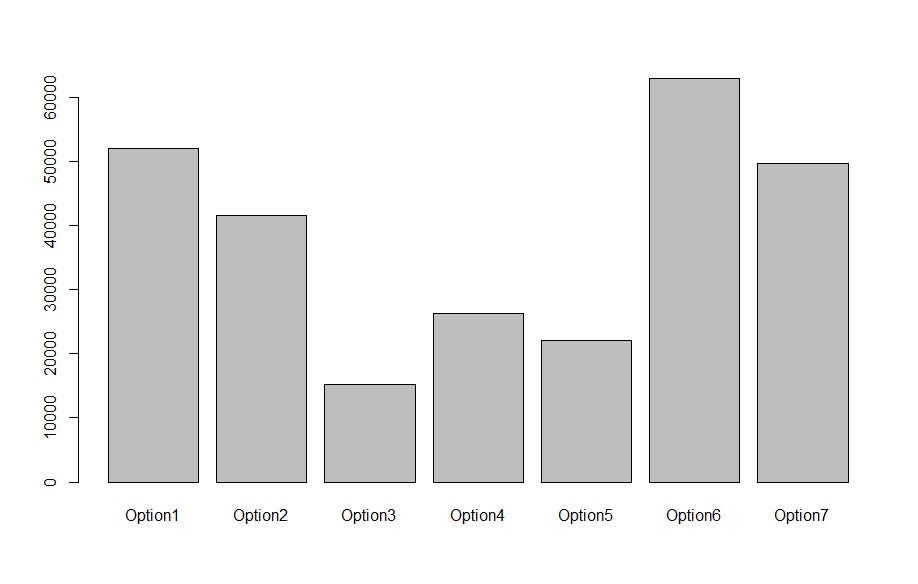

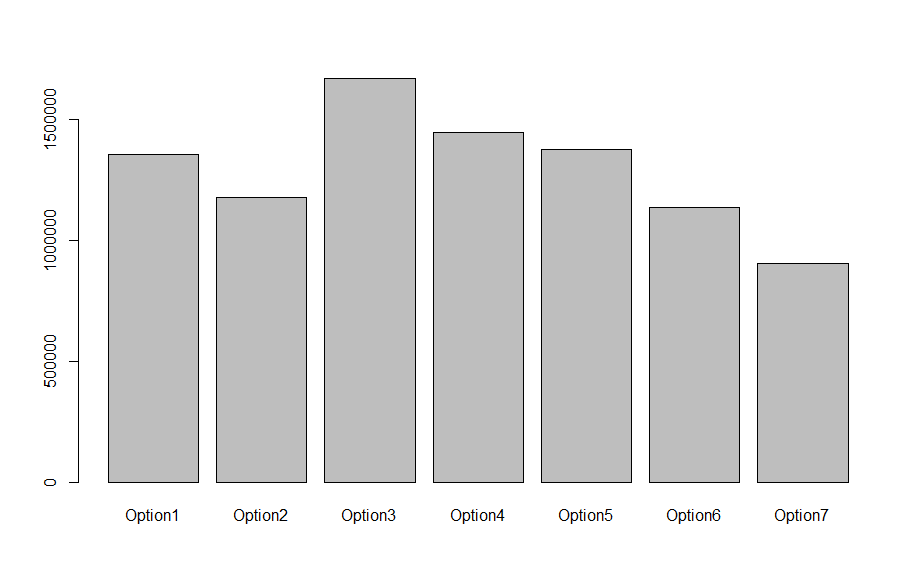

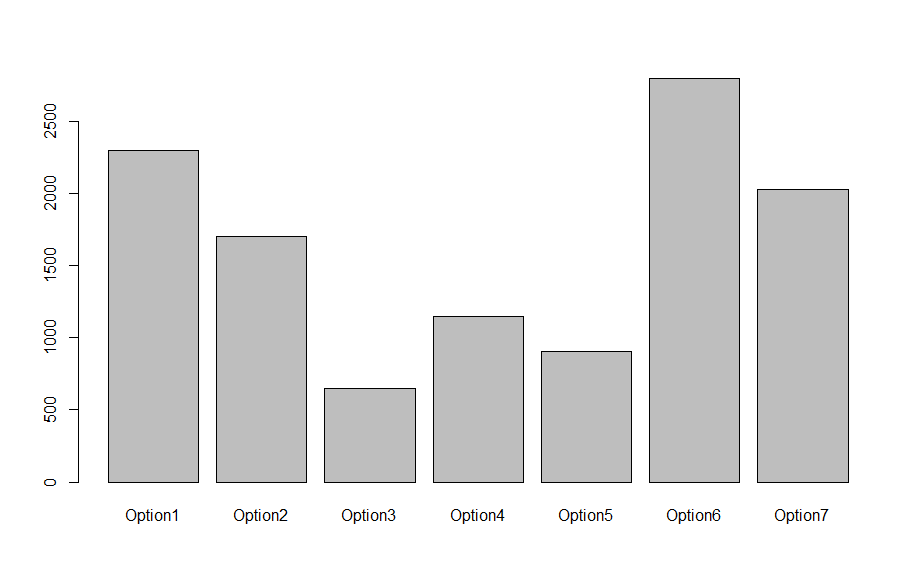

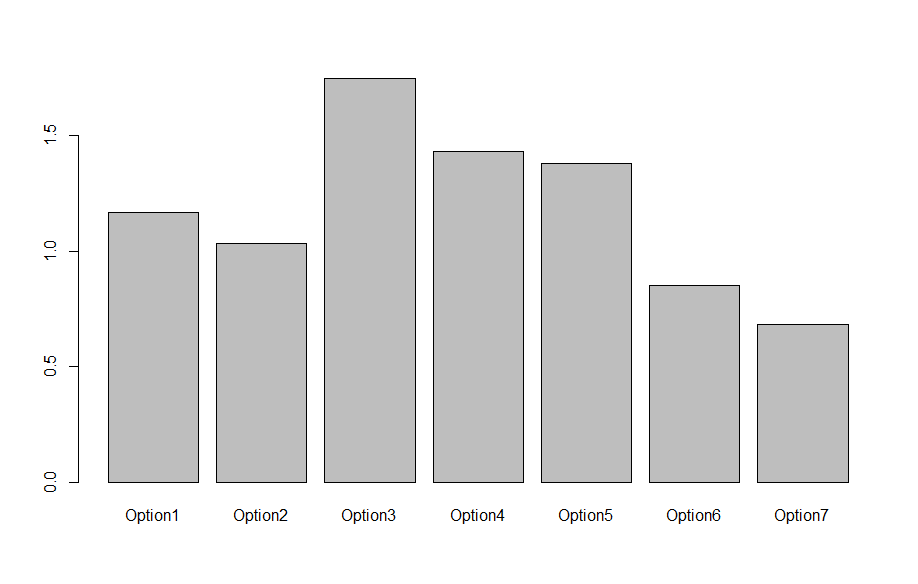

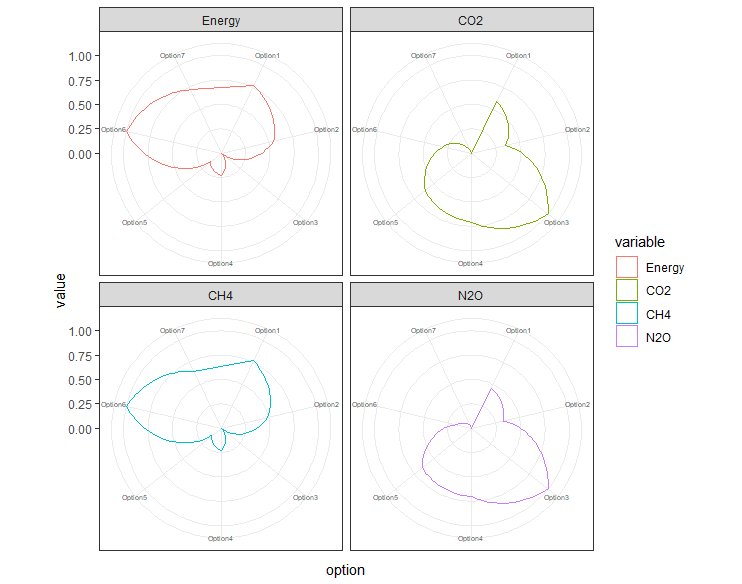

Building on the previous accumulated information, we proceeded to apply the LCA approach over these alternatives. To facilitate the comparison between the potential outputs induced from the different design scenarios, we created meaningful plots that clearly summarizes the different design contributions in terms of energy and gas emissions, which are displayed in the figures below.

Energy Consumptions Of Different Design Options.

CO2 Emissions For Different Design Options.

CH4 Emissions Of Different Design Options.

N2O Emissions of Different Design Options.

Radar Plot For The Different Design Options.

Conducting a superficial examination of the graphs displayed above and the energy and gas emissions measurements reflected by them, allow us to quickly distinguish the strengths and weaknesses of each alternatives. In fact, we can discern that option3 demonstrates the most efficient energy usage, while option6 lags behind others in regard to energy consumption, with an increase that surpasses 300% of option3’s energy performance, which proves to be largely significant. As a result, it can be deduced that employing Portland cement concrete in pavement structure is by far energetically rewarding than Asphalt concrete, even though the overlay rehabilitation action was more frequent in the latter option. However, through consolidating the three gas emissions values, option3 is judged as the most disadvantageous alternative in terms of environmental effect.

On the other hand, another beneficial feature than can be derived from the analysis of the plots is the embodied optimisation of engaging the Recycled asphalt pavement (RAP) in the asphalt composition. In effect, since options 6 and 7 share the same configuration and differ only in the RAP’s amount included in the composition, option7 overcomes its opposite one in each criteria. As an instance, it can be noticed form the graph that introducing 20% RAP into asphalt formulation has lead the energy usage to drop by more than 20%.

MULTI-CRITERIA DECISION ANALYSIS

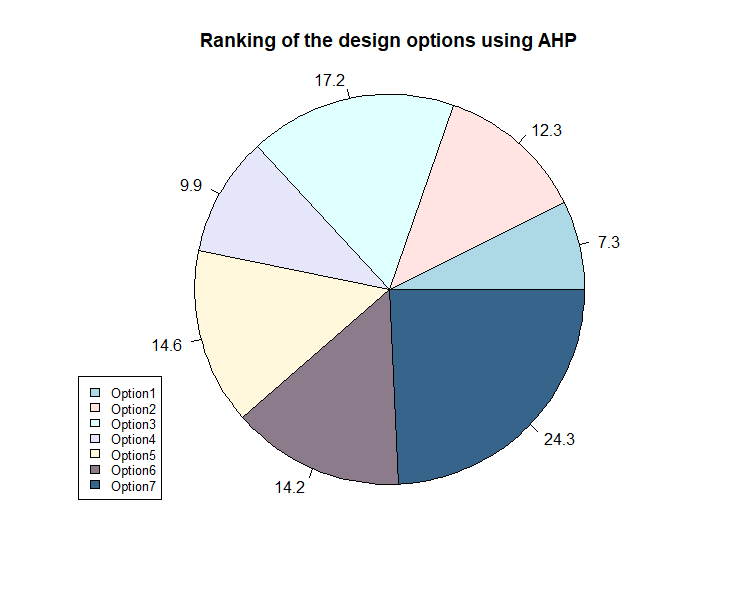

When multiple attributes are involved in the environmental impact assessment process of a large collection of conceptual designs, where some options are favorized with respect to some attributes, but fail to excel in other aspects, taking a decision about the optimal design to choose becomes complicated and challenging. Therefore, designers resort to applying the AHP Method to handle the multi-criteria decision analysis, in harmony with their priorities and preferences. In our case, we elected in the AHP method due its widespread use in infrastructure management. The multi-criteria decision analysis yielded the results recapitulated in the pie chart below.

The results illustrated above demonstrate that the MCDA mechanism converged ultimately to option7, as the ideal design alternative that best suits our motivations, which is materialized by the prioritization of CO2 performance as defined in the criteria pairwise matrix. Referring to the graphs inferred from the LCA approach, the 7th option embodies the optimal behavior in regard to CO2 emissions, among all design options, which is well compatible with our preferences. Moreover, it promotes the mitigation of the waste damaging effect, which adds significantly to its environmental benefits. However, the energy loading required by this option remains its major inconvenient, which largely exceeds the most efficient performance, reflected by the 3rd design option. In fact, a trade-off estimated approximately at 34 356 GJ is the huge implication that should be supported when opting for the 7th option.

From another perspective, if we assume alternative circumstances where the stakeholder’s preferences are directed towards the optimization of the energy bill associated with the design option, we could advocate the selection of the 3rd option, since it largely fulfills the optimisation objective due to the least amount of energy consumed, compared with the remaining design concepts. However, stakeholders will be in the obligation to deal with the huge size of the CO2 emissions engendered by this option.

REFERENCES

ATHENA INSTITUTE. A Life Cycle Perspective On Concrete And Asphalt Roadways: Embodied Primary Energy And Global Warming Potential.

Wang H, Thakkar C, Chen X, Murrel S, “Life-Cycle Assessment of Airport Pavement Design Alternatives for Energy and Environmental Impacts”, Journal of Cleaner Production (2016), DOI: 10.1016/j.jclepro.2016.05.090

Cristina Torres-Machi, Filzah Nasir, Jessica Achebe3, Rebecca Saari, and Susan L. Tighe. “Sustainability Evaluation of Pavement Technologies through Multicriteria Decision Techniques”. DOI: 10.1061/(ASCE)IS.1943-555X.0000504. © 2019 American Society of Civil Engineers.