Goal and Scope

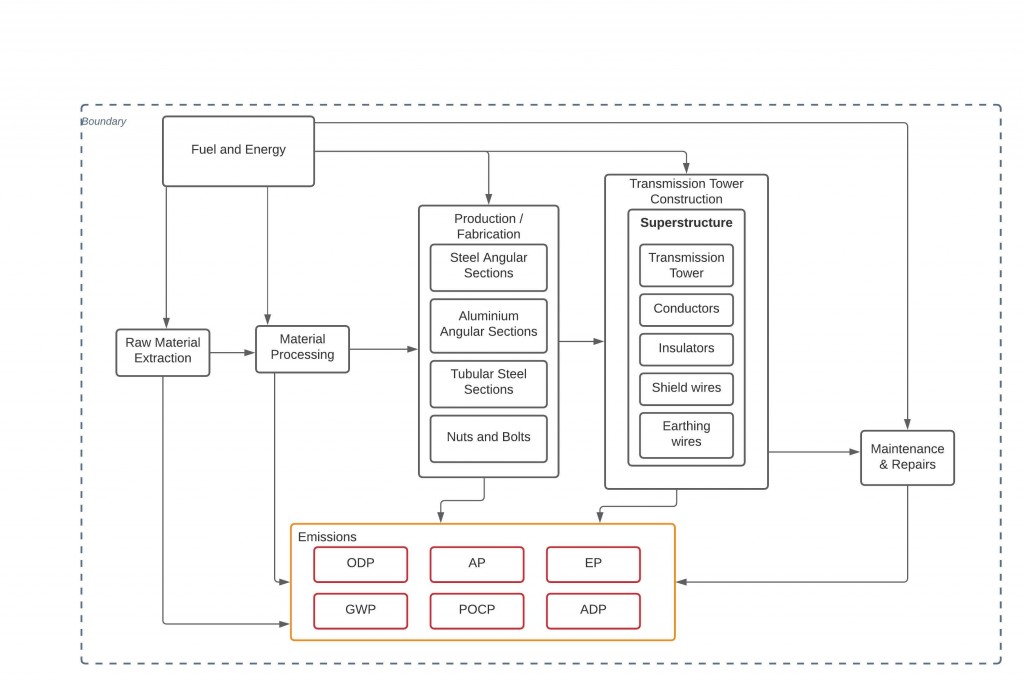

The goal of the following Life Cycle Analysis (LCA) is to carry out an environmental impact analysis of a transmission tower (TT). A TT doesn’t “emit” any green house gases however like most infrastructure, the green house emissions arise from raw materials’ extraction and processing, construction and maintenance. Hence, the emissions from these processes have been taken into account. This study doesn’t delve into the emissions caused by processes such as operations, transportation, dismantling, recycling, etc. They are beyond the scope of this study. Given that TTs are so common across borders in the modern world, this study might help governments and companies make more climate-friendly decisions.

The figure below gives an overview of the goal and scope of this study. As highlighted in the diagram, this study focuses only on the superstructure’s components of a TT.

Design Options

Before we start an LCA, it is important to decide on the functional units in order to compare various design options. In my case I am setting the functional unit as a tower with carrying capacity of 110kV. A similar approach of considering a tower with carrying capacity as the functional unit was utilized in [1]. The function of a tower/pole is to facilitate transfer of current from source to customers. The goal is to transfer electricity efficiently while meeting the safety standards. Its dimensions and configuration depend on a number of factors such as the power being transmitted, landscape, local regulations, etc. A tower/pole can be made from wood, concrete, steel, aluminum or alloys.

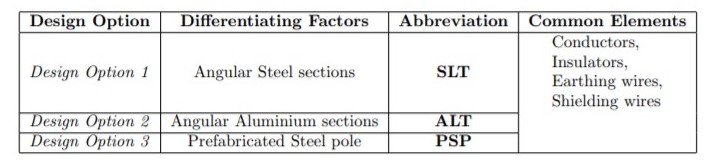

Since, wood and concrete poles are generally used to transfer voltages up to only 33kV, whereas the towers made from other materials are capable of carrying a wide range of voltages (including 110kV in our case), we will be considering three design options:

- Steel lattice tower

- Aluminum lattice tower

- Prefabricated Steel pole

Steel Lattice Tower

The most prevalent type of lattice tower structures are made from steel. Typically, they consist of angle sections (L or T-beams) and are assembled on site. The main reasons for using steel are its high strength and wide availability (hence lower cost).

Aluminum Lattice Tower

Aluminum lattice towers are similar to steel ones the differences being in the higher upfront material cost but lower maintenance costs. Aluminum towers are usually used in regions that are corrosive to steel.

Prefabricated Steel Pole

Prefabricated steel poles are as their name suggests, assembled in a factory and then installed on site. They are growing in popularity for their ease of installation and aesthetic value.

Materials

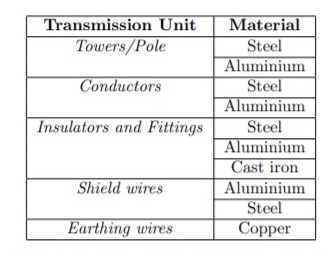

The following table lists the components and the materials used in those components.

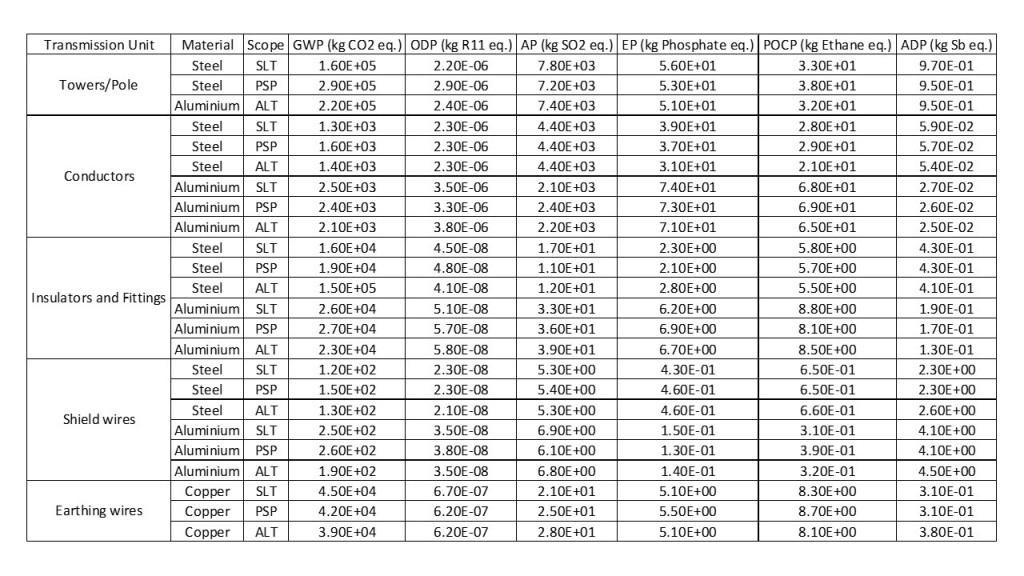

Now a brief overview of the elements and their environmental impact for each design option is provided in the next table and the same has been converted to a .csv file and used as the input for the Life Cycle Inventory Analysis

Life Cycle Timeline

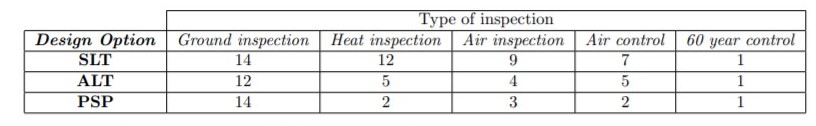

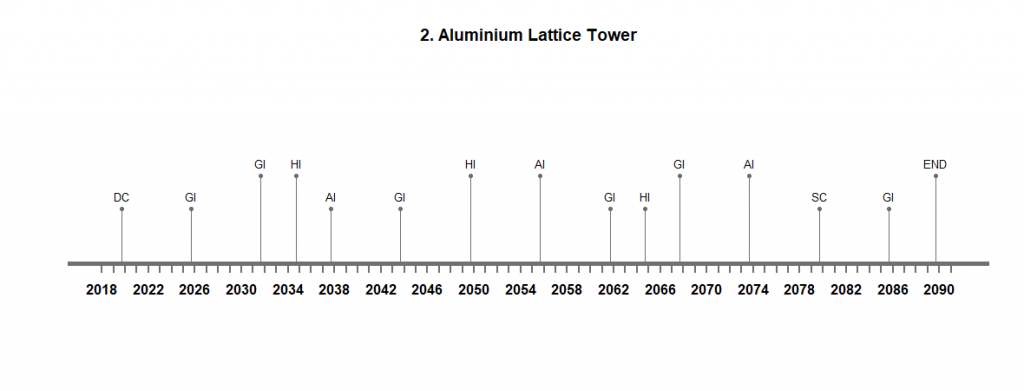

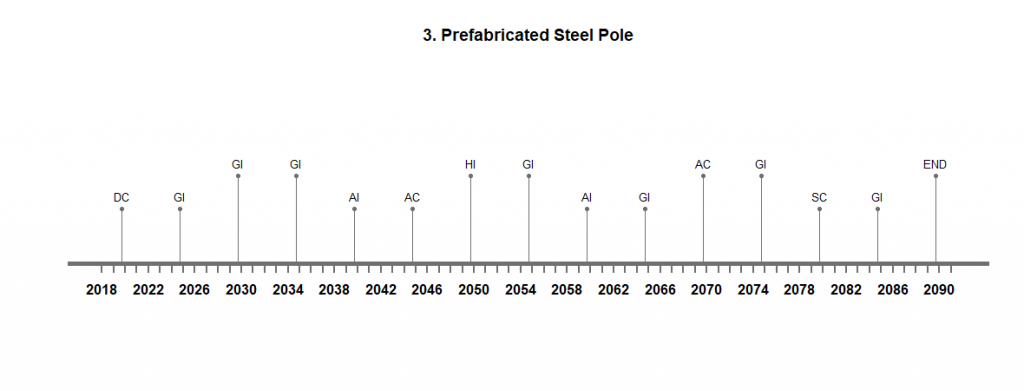

In the table below we can see the occurrences of the maintenance activities for various design options. A life cycle of 70 years along with the maintenance activities are adopted from [1]

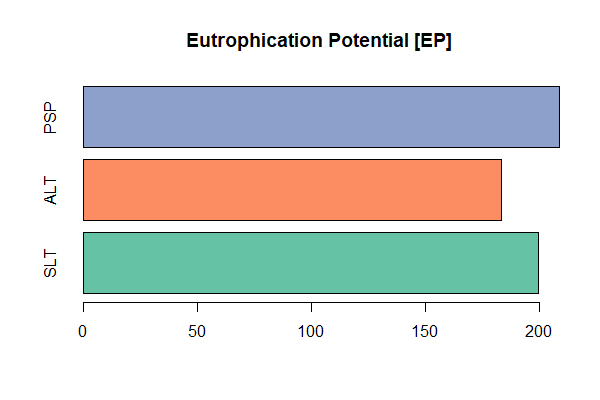

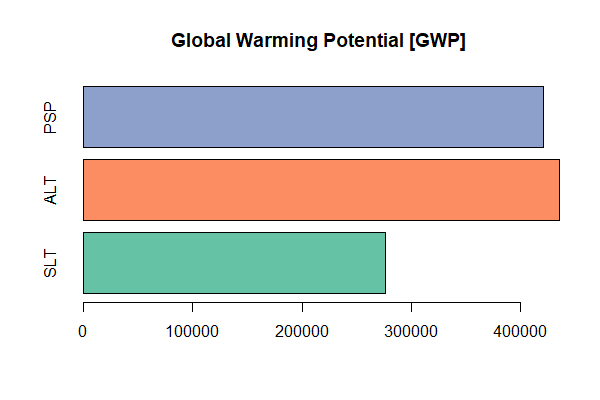

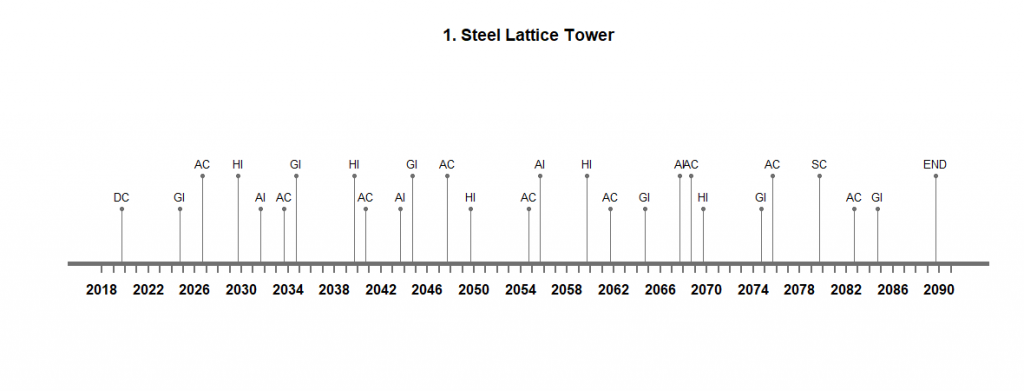

These values have been visualized in the following plots.

Life Cycle Inventory Analysis

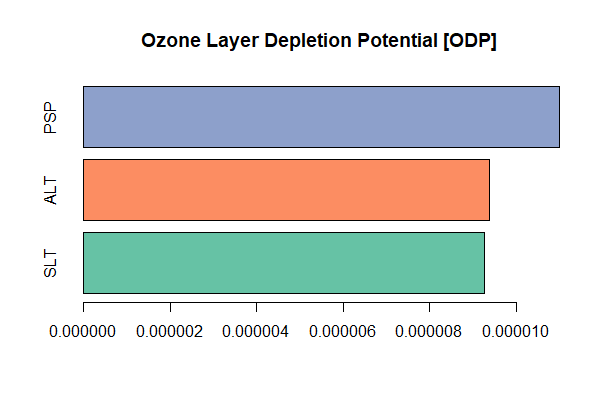

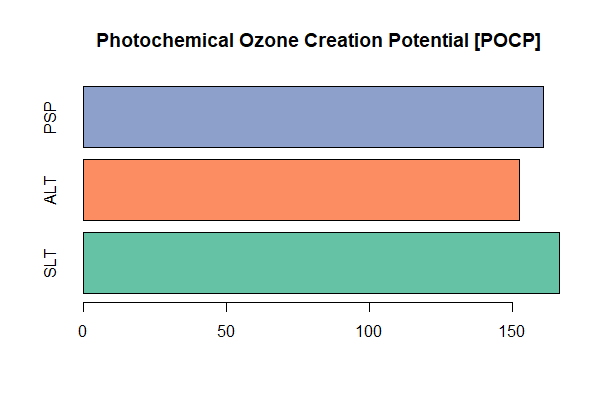

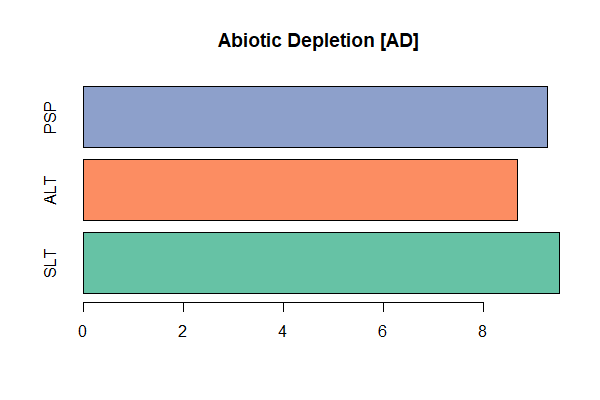

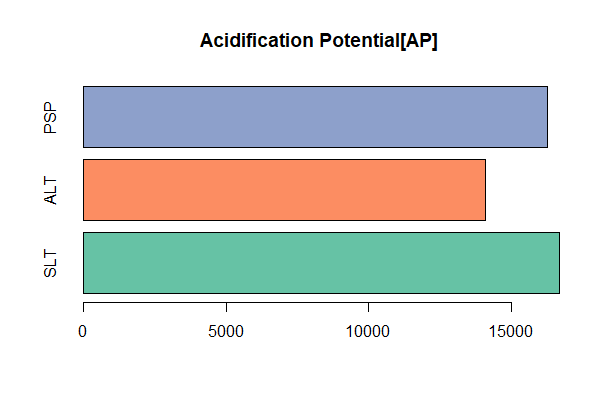

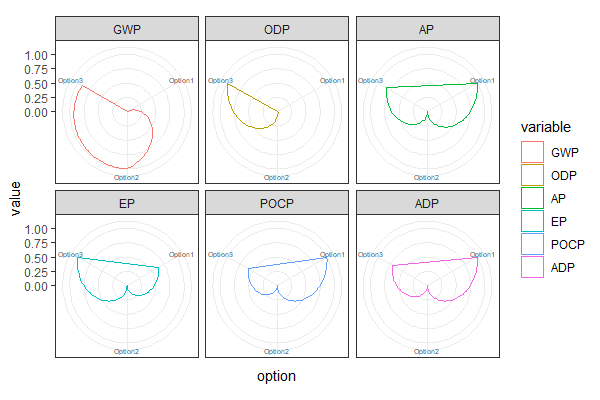

LCIA helps us understand the impact of the materials being used in each design option. Using R, the amount of GWP.ODP, AP, EP, POCP & ADP were calculated and visualized in figures below. When it comes to GWP, clearly ALT and PSP have a significantly higher impact than SLT. However, in almost all other categories the other options have a slightly higher impact than ALT. This however is misleading if we do not look at the scales. Once we look at the scale, it becomes clear that the overall impact of ALT is much higher than the other two options. in reality, SLT is much more common than ALT. Based on the LCI, that is a good thing for our climate. However, we need to be aware that this LCA’s scope is limited and the impact of the processes outside the scope might show a different picture.

Multi Criteria Decision Making

Using both an AHP and a TOPSIS approach lead to the same result. Both indicated that a Steel Lattice Tower is a better option.

Other Systems: