Life Cycle Assessment (LCA) plays a pivotal role in evaluating the environmental impact and associated costs of integrated systems with multiple subsystems, with a primary focus on environmental emissions. As industries increasingly adopt intricate and interconnected infrastructures, comprehending the comprehensive environmental implications becomes crucial. LCA provides a systematic approach to assess the entire life cycle of a system, including its conception, production, operation, and eventual disposal. In the context of integrated systems with multiple subsystems, LCA serves as a powerful tool to analyze the intricate network of environmental emissions. By considering diverse subsystems and their interdependencies, LCA facilitates the identification of significant emission sources, allowing decision-makers to prioritize mitigation efforts and foster sustainability in complex systems.

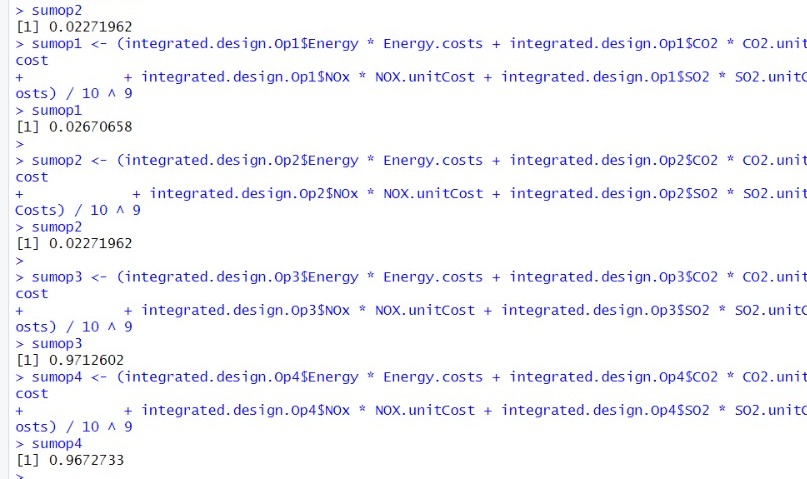

Scope and goal

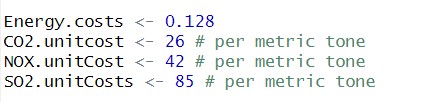

Within the Life Cycle Assessment (LCA) of our project, we comprehensively assess greenhouse gas emissions from material extraction through construction. This analysis extends to encompass maintenance scenarios, factoring in optimized subsystem plans. Consequently, we calculate emission values for gases and their associated costs, providing a holistic understanding of the environmental impact throughout the lifecycle of the infrastructure.

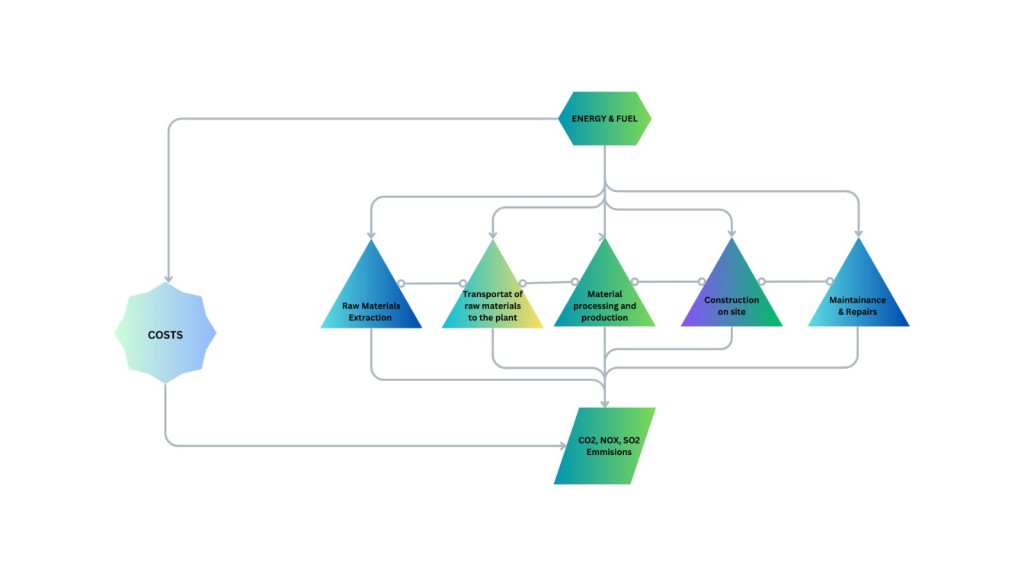

Figure 1 Scope and Boundaries

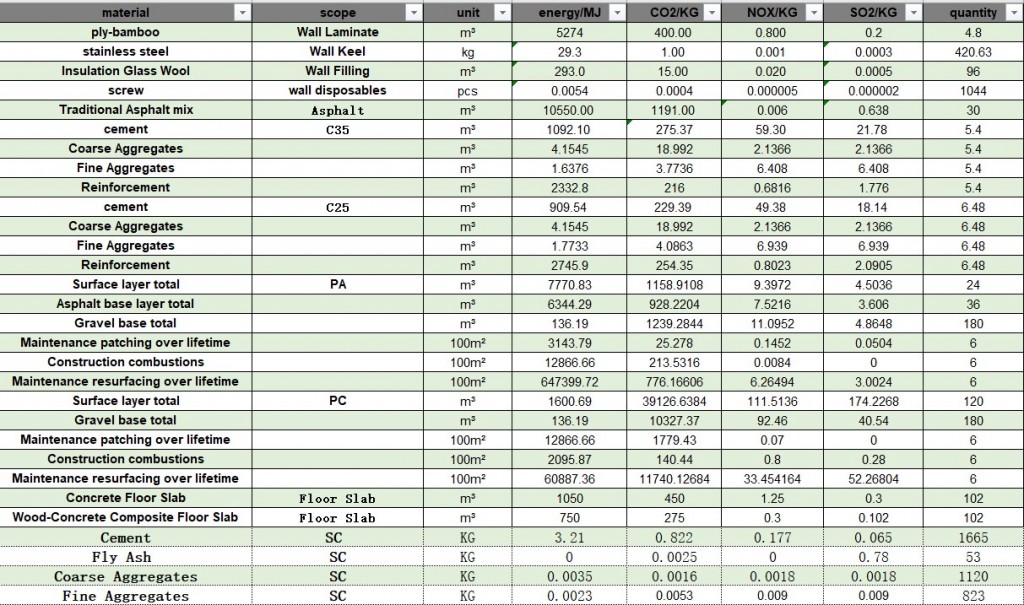

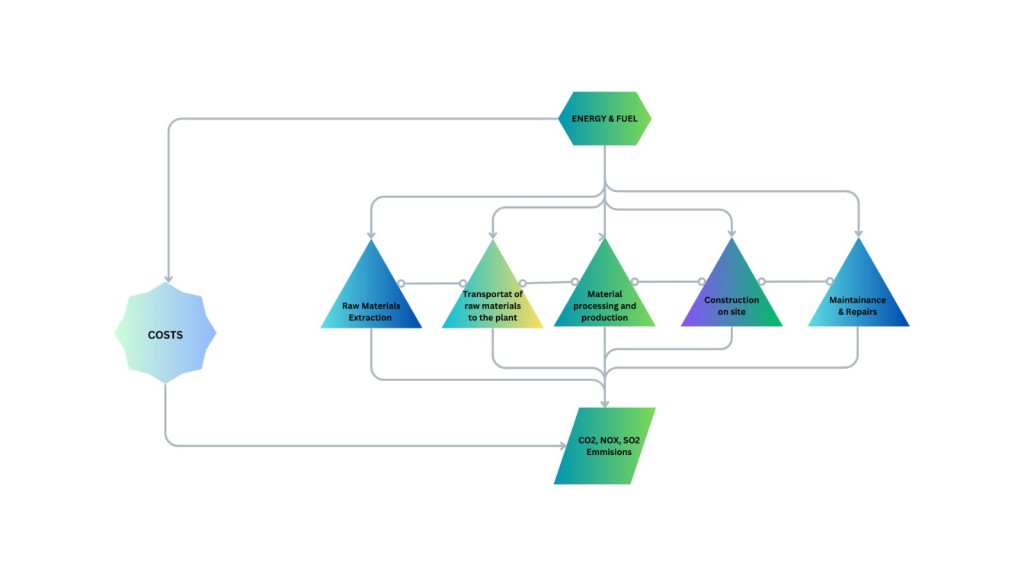

To perform the life cycle inventory, it is imperative to have the following table, outlining the quantities of CO2, SO2, NOx, and the chosen energy consumptions for our subsystems.

Figure 2 Energy Consumption And Emissions

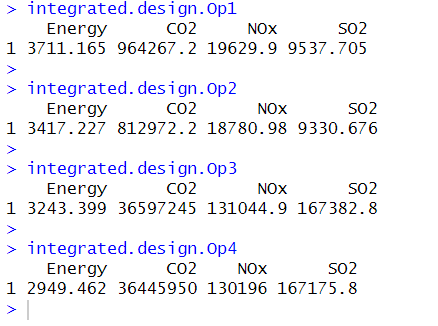

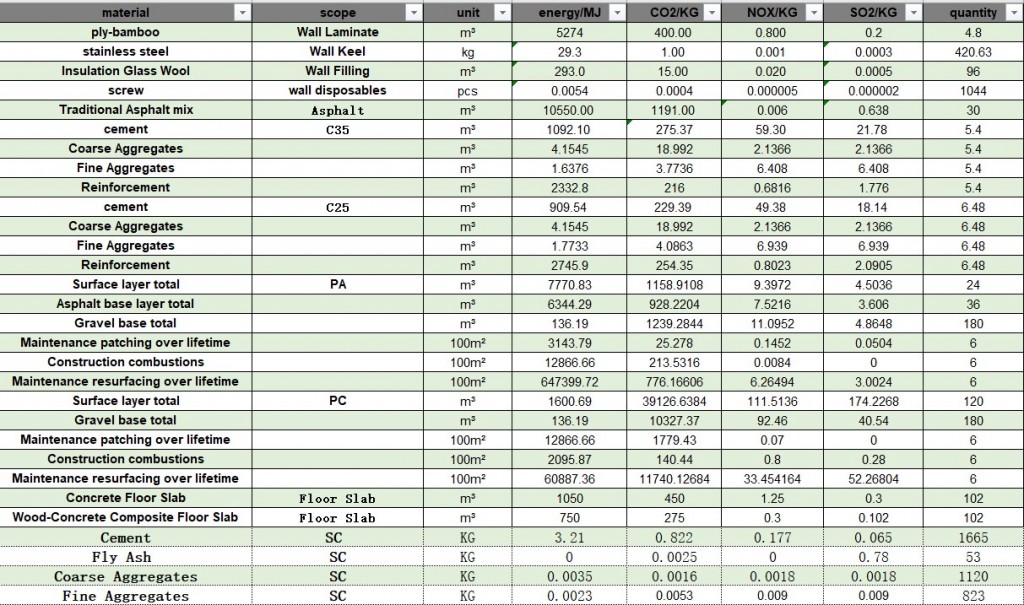

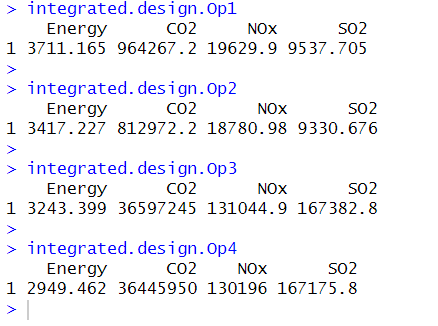

Life Cycle Assessment (LCA) was conducted for four distinct design alternatives, and the results are depicted in the figure below:

Figure 3 Energy Consumption and Emissions for Different Design Options