Motivation

The world population is rising by also rising withdrawal of freshwater for agriculture, industry and domestic uses. Thereby is the problem, that only 3% of the planets water resources are available freshwater. The other water resources are seawater with different salinity. [1] One way to provide additional fresh water: Desalination. Water desalination can be a promising and viable solution to provide fresh water from seawater or brackish water in rural or urban areas. The form of desalination with the highest market share is the reverse osmosis (RO), accounting for about 65% of global desalination capacity. Known disadvantages of RO systems especially for the treatment of seawater are the higher energy demand and the deposition of brine. [2] Hence is the assumption, that the failure rate by seawater RO units are higher than of brackish water RO units. According to the assumption the focus will be lead on seawater RO plants.

Principle of a RO plant

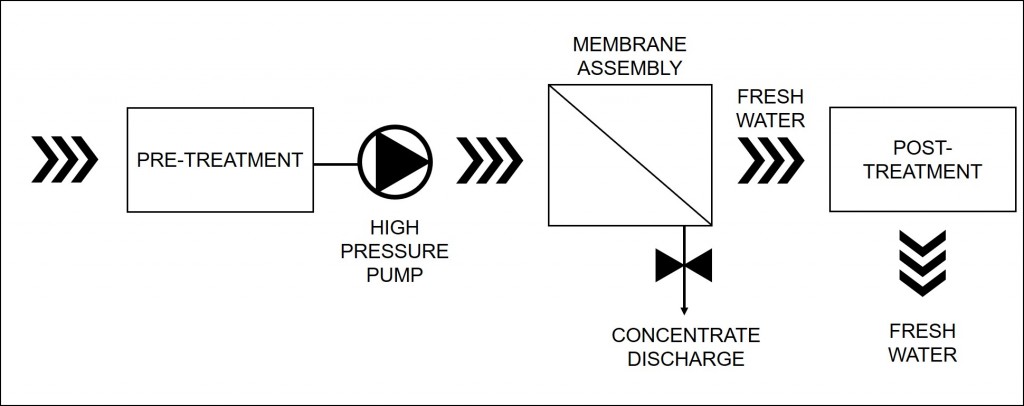

The principle idea of a RO plant is to separate via diffusion water and salt with a semipermeable membrane inside a pressure vessel (RO unit) and is shown in figure 1. A highpressure pump installed in front of the RO unit is needed to provide osmotic pressure on the feed. To minimize blockage of the membrane a pre-treatment unit is installed to remove particulates. Afterwards a post-treatment unit is needed for disinfection.

Figure 1: Flow chart of RO plant system (own representation)

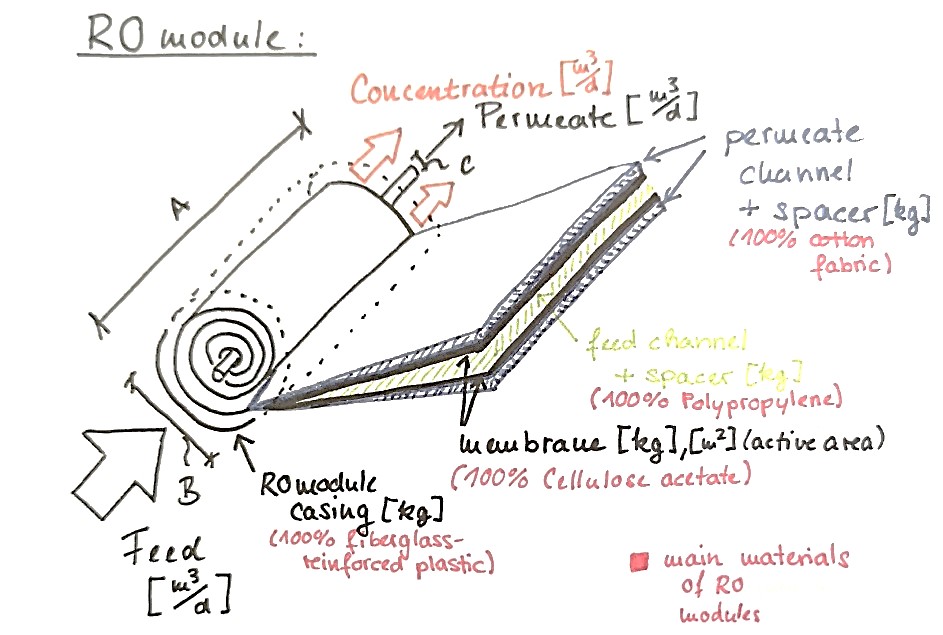

The whole system is based on the sensitivity of the membrane for scaling, fouling, oxidation damage, etc. In general, it is observed that RO membrane and water tower represent the major parts of embodied energy (EE) in the life cycle analysis of RO plants. [2] So, in the following the RO module as the main subcomponent in the system including the seawater membrane is considered. Figure 2 shows the typical RO module structure including the material properties.

Figure 2: RO module indicating main components and its dimensions (own representation)

For the production of a fully constructed RO module a RO casing, the membrane, a permeate spacer and a feed spacer is needed.

General characteristics

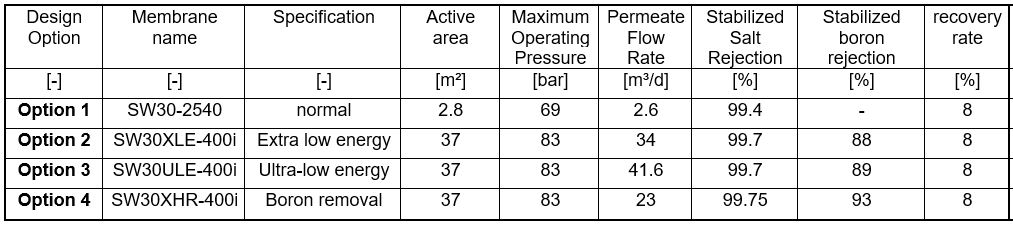

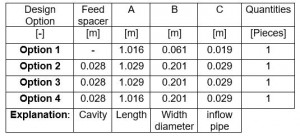

The typical RO plant has a life cycle period of 20 years and are generally sensitive about the feed pressure, the feed water composition, the recovery rate and the temperature especially in the RO unit. [2] Every three to five years the membranes of the RO unit should be replaced. [3] There has also been made the assumption that two RO units are working parallel, because of the maintenance strategy. If one RO unit is maintained, the other can still provide fresh water for the community. As in Assignment 2 before the different design options are different seawater-membranes of the brand Filmtec, which have all different performance designs, shown in Table 1.

Table 1: Different design options of Filmtec membranes

Table 2: Dimensions of different options ([4],[5],[6],[7], 2020)

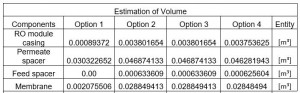

Table 3: Volume of the RO module options

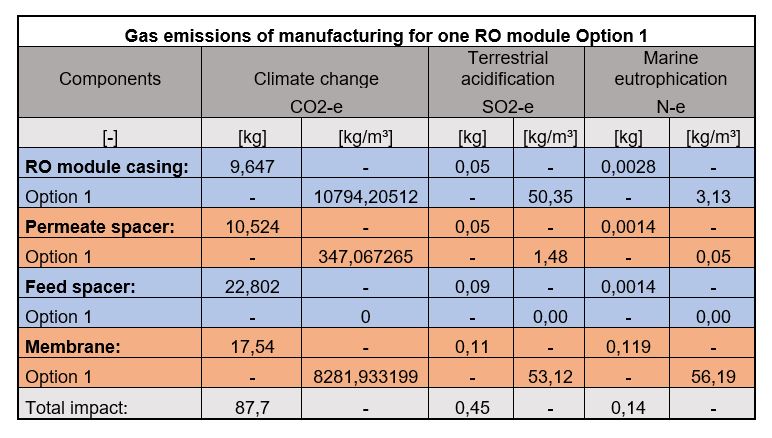

In the following there is a focus on the membrane option 1.

Environmental costs of Option 1

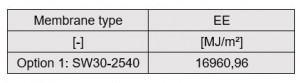

Table 4: Environmental cost parameter of option 1

Table 5: Embodied Energy (EE) of Option 1

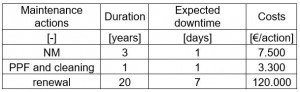

Considered maintenance actions and monetary costs

Table 6: considered maintenance actions and monetary costs

NM means a new membrane for the system, which happens every 3 to 5 years. PPF and cleaning means the cleaning of the RO unit and the pre- and postfilter exchange, which has to be done every year. The renewal of the whole system has to be done every 20 years. The expected downtime and the costs are estimated by engineered experience. The different interventions because of maintenance are visualized in a timeline below.

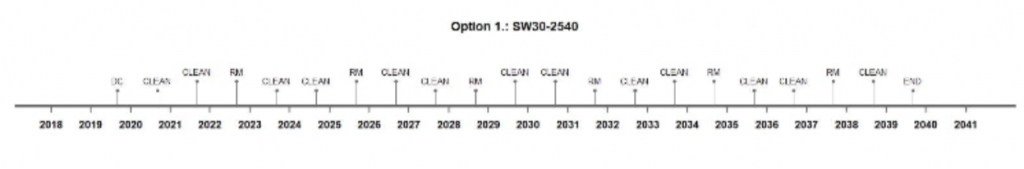

Intervention timeline

Figure 3: Maintenance interventions timeline

It is important here to keep in mind that the Reverse Osmosis Plant just has an life time of 20 years. In the integration of the whole system it faces a total life span of 100 years. So, after 20 years there will be in the following a renewal of the whole system with da downtime of 7 days and total costs of 120.000 € as described before in table 6.

Literature

[1]: http://easyponic.com/water-footprint-hydroponics/, last checked: 10.02.2020

[2]: Cherif, Habib and Belhadj, Jamel (2018): Sustainable Desalination Handbook. Environmental Life Cycle Analysis of Water Desalination Processes; Chapter 15, Online at: https://www.sciencedirect.com/book/978012892408/sustainable-desalination-handbook. Last checked: 10.02.2020

[3]: https://www.best-osmosis-systems.com/ro-maintenance/, last checked: 10.02.2020

[4]: datasheet for the membrane SW30-2540: https://www.lenntech.com/products/membrane/sea/general/reverse-osmosis-desalinationmembranes.htm. Last checked: 10.02.2020

[5]: datasheet for the membrane SW30XLE-400i: https://www.lenntech.com/products/membrane/sea/general/reverse-osmosis-desalinationmembranes.htm. Last checked: 10.02.2020

[6]: datasheet for the membrane SW30ULE-400i: https://www.lenntech.com/products/membrane/sea/general/reverse-osmosis-desalinationmembranes.htm. Last checked: 10.02.2020

[7]: datasheet for the membrane SW30XHR-400i: https://www.lenntech.com/products/membrane/sea/general/reverse-osmosis-desalinationmembranes.htm. Last checked on: 10.02.2020