Purpose of Maintenance Planning

In order for a system to function flawlessly its subsystems require maintenance. Often the dis-functionality of one subsystem also affects the functionality of other systems. Furthermore, maintenance and repair works on one sub-system can obstruct the functionality of other subsystems. If e.g. some columns in an office building are damaged, parts of the building have to be closed for repair works not only because of the space needed for the repair work but also due to security threats. Roads under construction limit the access to the office building not only for employees but also for possible customers.

This is why it is important to bundle maintenance work to decrease the duration during which the system is dysfunctional. Moreover, increasing the time spans between maintenance interventions leads to longer periods of an undisturbed system function.

Single Maintenance Plans

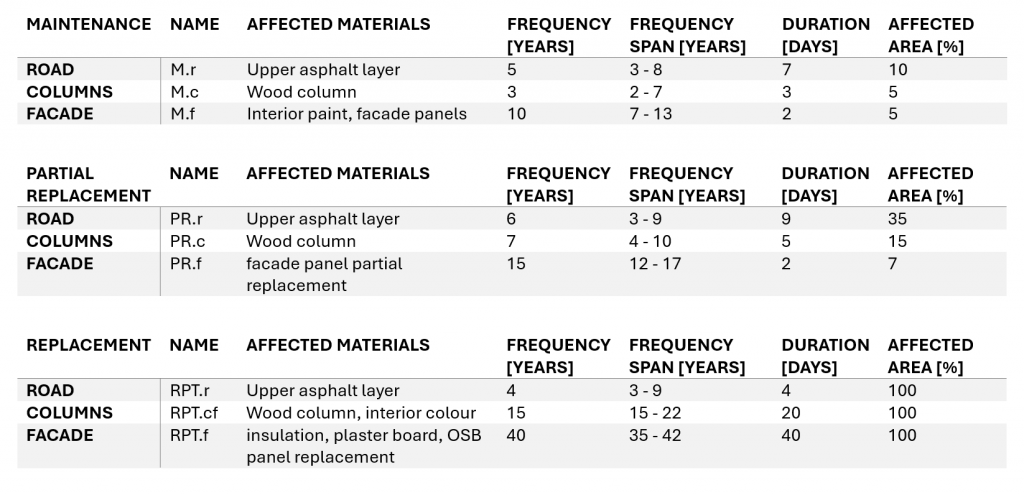

The tables below show the maintenance interventions required by the individual sub-systems.

This maintenance plan does not include any adjustments between the maintenance plans if the individual systems other that the replacement of the interior facade colour is fused with the column replacement since frequency and duration are very similar in contrast to the interior colour replacement ant the replacement for the rest of the facade system.

The life time of the integrated system is assumed to be 65 years. According to this maintenance plan the integrated system would be dysfunctional for 325 days throughout its lifetime.

Adjusted Maintenance Strategy

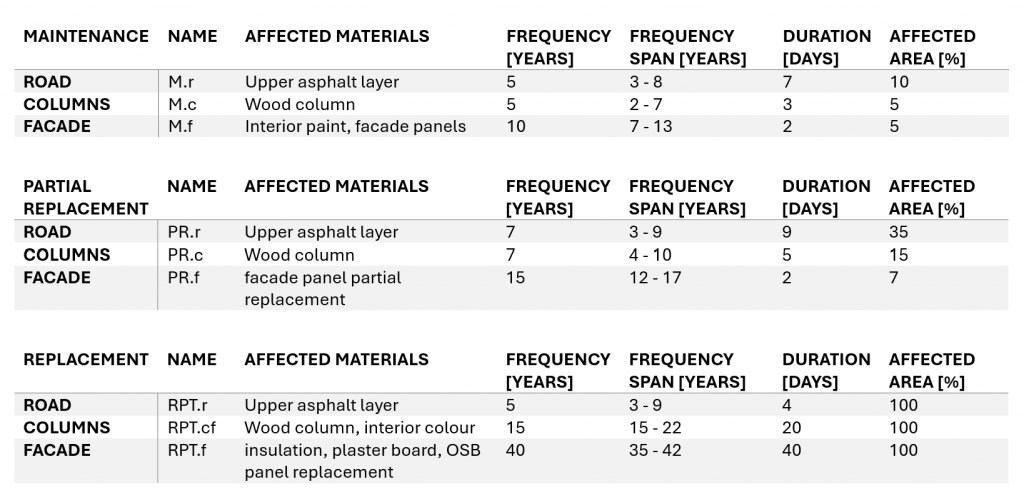

The tables below propose a maintenance strategy with aligned frequencies within the frequency spans.

Developing this adjusted maintenance strategy leads to a reduction of days the system does not work from 325 to 243 days.

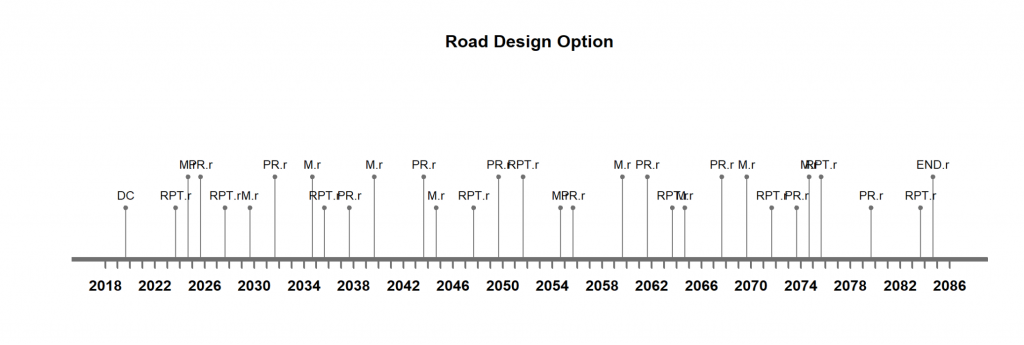

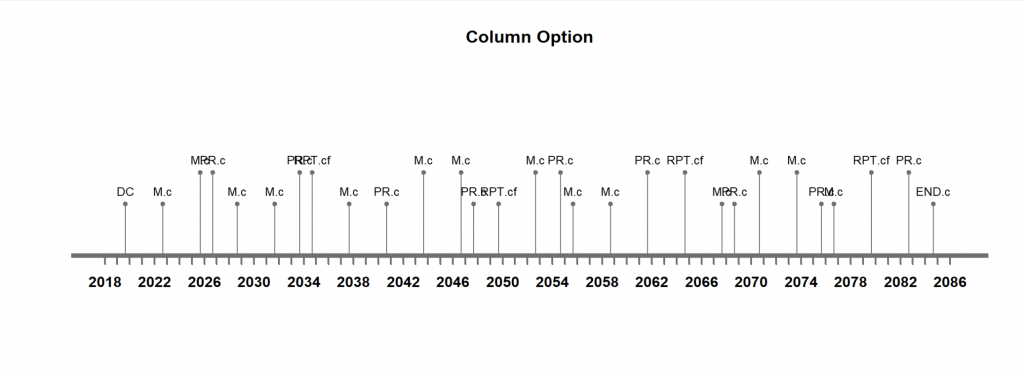

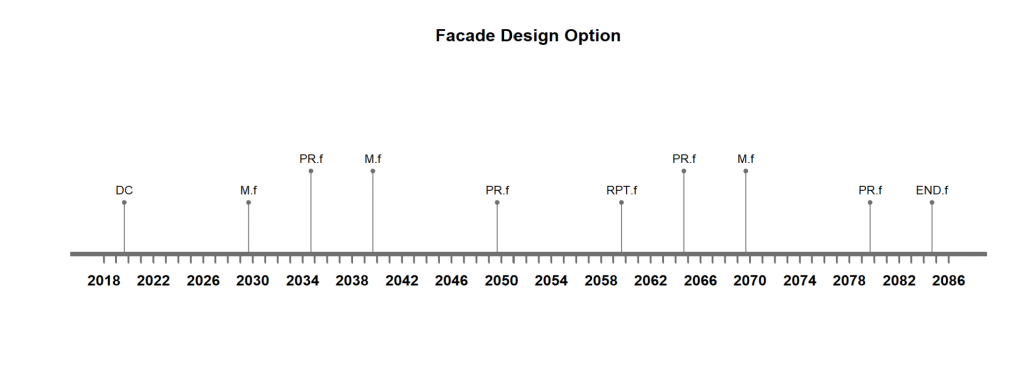

The timeline of maintenance activties for systems are shown as below.

In conclusion an aligned maintenance strategy is crucial to increase the functionality of interconnected systems.

Automated Maintenance Strategy

We aim to optimize the maintenance planning strategies by aligning or merging interventions for subsystems. The Pareto front is utilized based on our defined ranges of interventions of subsystems for multi-objective optimization solution. The parameter n.grid is set to 4, resulting in a combination of 26,144 lifetime scenarios in total.

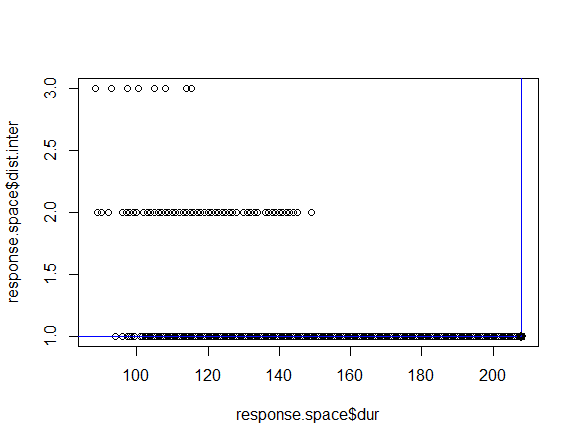

The goal is to find the optimal maintenance by minimizing the total number of intervention days while simultaneously maximizing the distance between interventions. There is a trade-off between minimizing the total duration and maximize the distance of intervention. On one side, the shorter duration lead to more frequent interventions, on the other side, the longer intervals occur in increasing of total duration. There are 224 samples representing the optimal alternatives with rankings, details are shown in the figure below.

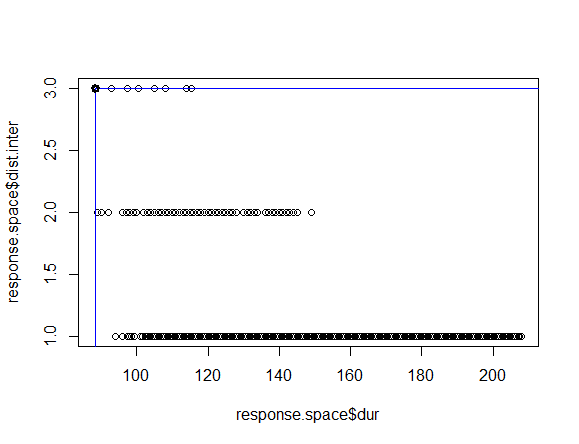

Based on the defined preferences, the first Pareto chart is generated under maximization total duration and minimizing the distance between two successive interruptions. And the second Pareto chart is generated based on the opposite preference.

The plot above shows the non-pareto front pointing to the worst possible solution. Instead of supporting the goal of creating a well functioning system, this solution has a minimal distance between solutions of 1 year and a maximum of 204 days in which the system is dysfunctional.

In the plot above the blue lines represent the Pareto Frontier , showing the optimal trade-off between duration and distance of two successive interventions. And the dark black spots are indicating the best alternative according to the defined reference. According to the results the optimal maintenance schedule solution can provide a distance of 3 years between maintenance intervention and reduce the days the system is not working from 204 to 88 days. In conclusion the level of integration of subsystem maintenance has a huge impact on its the functionality.

By comparing the optimal solution of 88 days determined through automated maintenance integration with the number of days achieved through manual aligning which is 243 days the potential of this method becomes apparent. Therefore automated maintenance integration is a good tool to support engineers in decision-making based for system maintenance. Also, the decision makers will gain a better understanding of how the optimal alternatives when adjusting maintenance strategies, planning and management.

| Main Page | Introduction | Integration Context of the Civil Systems | Maintenance Strategies | Life Cycle Analysis | Multi-Objective Optimization |