1. Introduction:

To begin with, due to the climate change new energy goals have been aimed by many countries. To achieve these goals nearly/net Zero Energy Building (nZEB) standards had been developed by a union of European Countries. According to the research that has been done, Water Flow Glazing (WFG) façade systems could play a key role in designing buildings with respect to nZEB standards.

The energy consumption in modern life is constantly rising and with approximately one third of the total energy consumption buildings are among the most significant consumers. In the last decade, almost 60% of the total net electricity consumption in Organization for Economic Co-operation and Development (OECD) economies came from the building sector, including both residential and commercial buildings [1]. Architects and engineers are driven by this fact to improve energy efficiency and develop innovative technologies for nZEB. In contemporary architecture, glazing comprises most of a building’s façade surface, therefore windows have an increasing impact on energy efficiency of buildings. By using advanced glazing technologies and materials can reduce the energy demands and improve indoor environment.

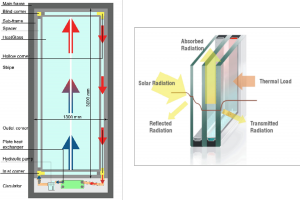

Fig.1: WFG Modular Unit, Madrid, Madrid 2019 (Left), Thermal and solar behaviour(Right).

1.1 System Overview:

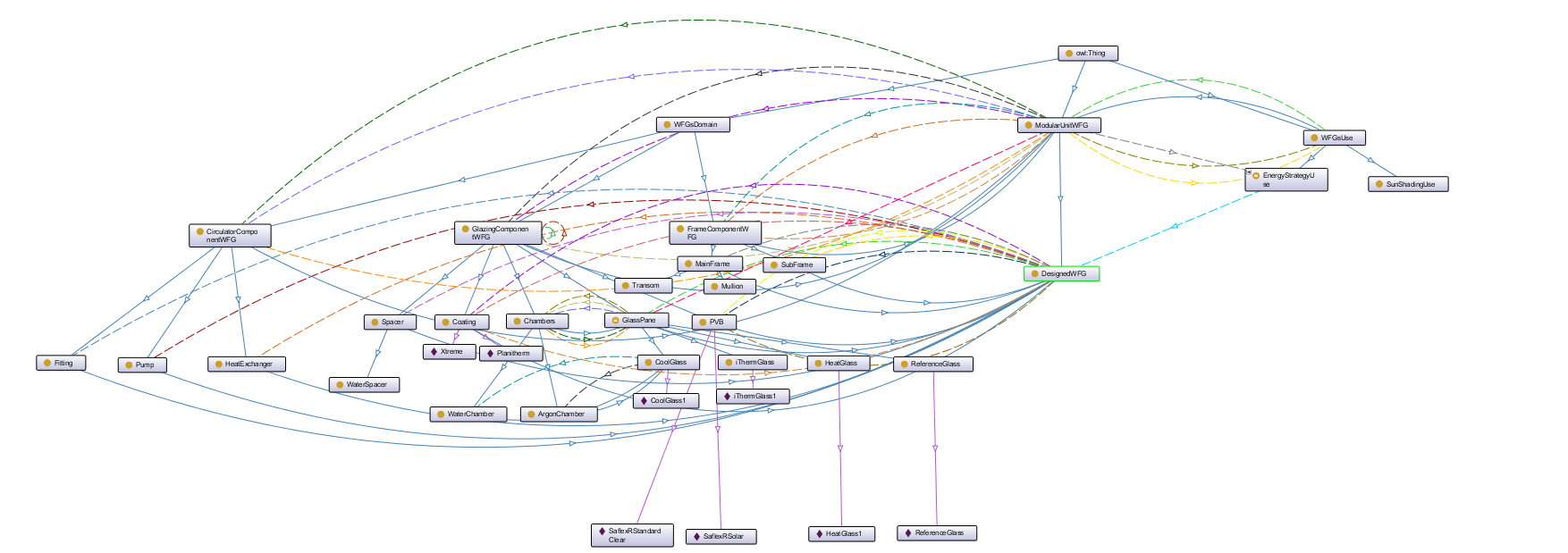

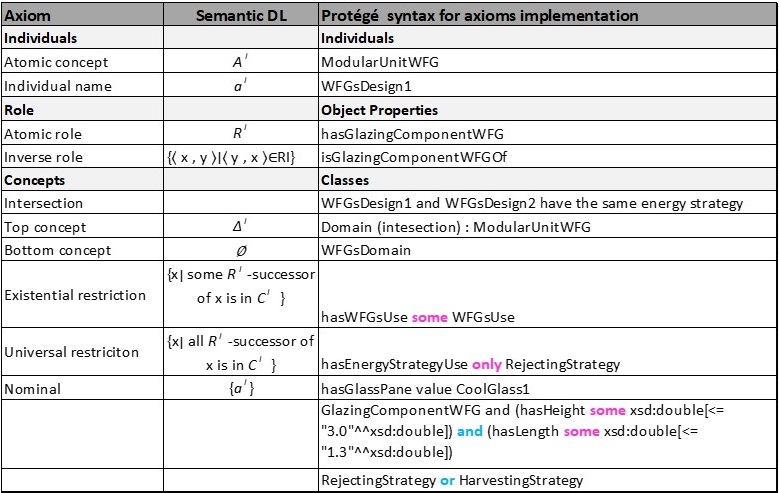

The WFG system is consist of a double or triple glazing with water chamber attached to a circulator that circulates water in a closed circuit, laminar flow, exchanging heat with the surrounding environment. Integrating the WFG system in a building envelope requires an aluminum frame that can be used to allocate the hydraulic installation. The WFG module is the main component of the unitize curtain wall system, which consists of three main components: glazing, circulator, and frame. To maximize daylight utilization in buildings and achieve energy savings for nZEB, the correct selection and assembling of components is essential. The schematic of a typical modular unit -can be shown in the Figure 1- composed by a glass pane with an argon cavity and water cavity between separate glass panes. Within the cavity, a specially designed spacer and corners ensure a design flow rate for the water. The inlet an outlet parts of the WFG are connected to a slim circulator that consists of a plate heat exchanger and hydraulic pump to permit fluid to circulate in a closed circuit within the water cavity. To facilitate installation on site, an aluminum frame composed of a main frame and a subframe includes the hydraulic installation and the glass in a module. Accurate choice of glass depends on the building’s location, its purpose, and its energy strategy. The glazing catalogue is based on the spectral properties of each layer and interphase of the glass panes, which will provide the spectral and thermal properties of the whole sandwich. In the WFG ontology, these thermal and spectral properties could be found with their instantiations.

2. Developing the ontology:

As Noy and McGuinness emphasized, the scope of the ontology can be determined by constructing a list of questions (competency questions) the knowledge base should be able address.

1. What is the purpose?

As stated above, advanced glazing technologies will be highly important in the coming decades, in terms of its energy efficiency and ability to integrate with other systems such as Heating, Ventilation, Air-Conditioning (HVAC). Therefore, knowledge formalization of rather specific technologies such as WFG systems could be highly significant and valuable for engineers in the design process and can play a major role in their widespread use.

2. What is the scope?

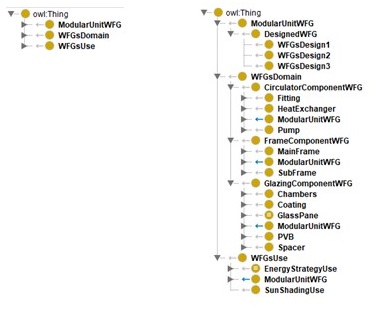

WFG systems’ domain is mainly composed of three main categories: Glazing, Circulator and Frame. WFG ontology for designing modular units will provide its user to choose the appropriate configuration out of the sub-categories of the main components that mentioned above, according to the buildings chosen energy strategy (harvesting, rejecting).

3. Who are the intended users?

Façade engineers, integrator and researchers who are working on this field.

4. What is the intended use?

This is an ontology for designing Water Flow Glazing façade systems as modular units. Through the ontology, the end-user will find variety of options in terms of energy strategy and corresponding glazing choice for composing WFGs.

Fig.2: The divided categories of Modular Unit WFG uses.

Fig.3: OntoGraf showing the detailed relationships between the classes and subclasses

3. Interface with other systems:

Façade systems: The WFG could be used as façade element and interior partitions (walls and ceilings) and could replace existing façades entirely. The interaction between façade systems and their characteristics (g-value, U-value) can be actively controlled in order to achieve the best energy performance.

Heating, ventilation, air-conditioning (HVAC) systems: As a radiant heating and cooling element, WFG plays an essential role in a building’s HVAC system. WFG can cover 100% of the costs associated with the standard HVAC system if the common partition wall is also replaced by modular WFG.

Renewable energy sources: WFG façade elements serve as transparent low temperature solar collectors. Compared to conventional solar collectors, WFG has relatively low efficiency (below 40%). Vertical installation and façade orientation are the main reasons for this.

Illumination: The improved natural illumination of interior spaces is one of the benefits of WFG façade elements. Thus, artificial lighting is rarely needed, which reduces costs. This helps meet nZEB requirements.

Fig.1: The divided categories of timber formwork uses.

References

- Santamouris, M. Energy and Climate in the Urban Built Environment; James and James Science Publishers: London, UK, 2001

- Moreno Santamaria, B.; Gonzalo, F.d.A.; Pinette, D.; Lauret Aguirregabiria, B.; Hernandez Ramos, J.A. Industrialization and Thermal Performance of a New Unitized Water Flow Glazing Facade. Sustainability2020, 12, 7564. https://doi.org/10.3390/su12187564

- Noy, N. & Mcguinness, Deborah. (2001). Ontology Development 101: A Guide to Creating Your First Ontology. Knowledge Systems Laboratory. 32.

- Protege Tutorial by Fabio Papacchini

- Moreno, Belen & del Ama Gonzalo, Fernando & Lauret-Aguirregabiria, Benito & Hernandez, Juan. (2020). Experimental Validation of Water Flow Glazing: Transient Response in Real Test Rooms. Sustainability. 12. 5734. 10.3390/su12145734.

- InDeWag, Case study for Bulgarian- and Spain- Demo-sites, different variations of façades. https://www.indewag.eu/deliverables.php

- Nikolaeva, Miglena & Stoyanova, Maya & Ivanov, Plamen & Tchonkova, Kalina & Stoykov, Rumen. (2019). New generation nZEB – Demonstrational Pavilion with water flow glazing and roof mounted PV system. AIP Conference Proceedings. 2075. 200015. 10.1063/1.5091440.

- Moreno Santamaria, B.; Gonzalo, F.d.A.; Pinette, D.; Lauret Aguirregabiria, B.; Hernandez Ramos, J.A. Industrialization and Thermal Performance of a New Unitized Water Flow Glazing Facade. Sustainability2020, 12, 7564. https://doi.org/10.3390/su12187564

- Sebastian B. (2011). A Practical Guide To Build OWL Ontologies Using Protégé 4 and CO-ODE Tools Edition 1.3.

Download the Ontology:

To the Water Flow Glazing Façade Systems Parametric Modelling:

Water Flow Glazing Façade Systems: Parametric Modelling