Integration Context

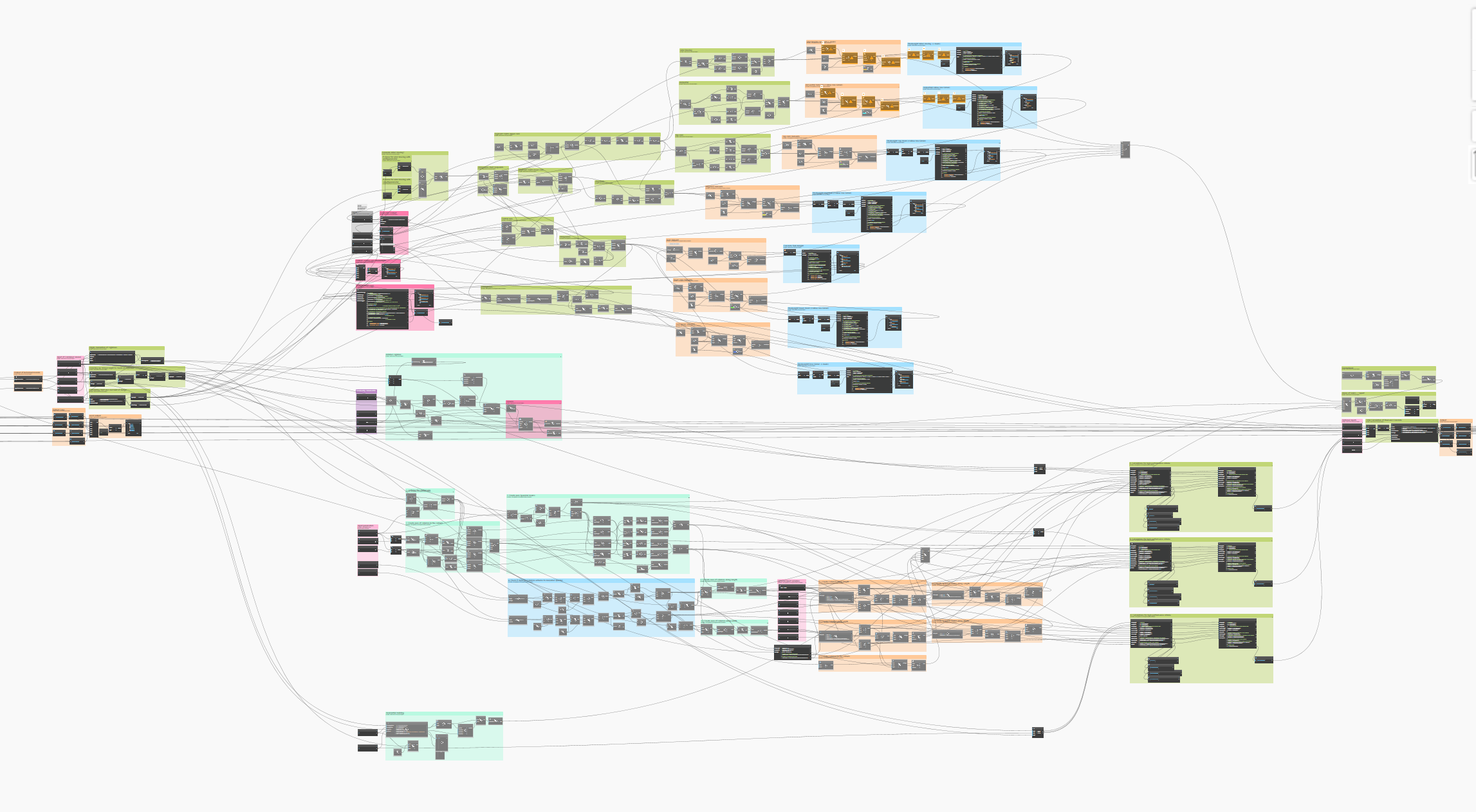

Our combined parametric model integrates four distinct models: a truss bridge, two high-rise buildings, and a residential building. These models were unified within an urban context by arranging the three buildings side by side, with the two high-rises positioned at the edges and the residential building in the center. The combined model represents a parametric design of a building complex featuring a pedestrian bridge that connects the two high-rises over the residential building. This design facilitates faster pedestrian movement between the upper floors of the high-rises, reducing reliance on traditional vertical infrastructure systems such as stairs and elevators. The primary objectives of the model include geometric dimensioning, material quantity calculations (concrete, structural steel, and reinforcement), and cost analysis to enable economic comparisons between design alternatives.

To achieve these goals, all individual models were adapted to align with the newly defined context. Key adjustments included creating new and relevant interfaces between the models, replicating functionalities to extend their capabilities, correcting inconsistencies, performing geometric translations to establish fixed reference points, generating a terrain, redefining inputs and outputs, and expanding the required modules for the new objectives. The combined model primarily focuses on providing planners with comparative design options.

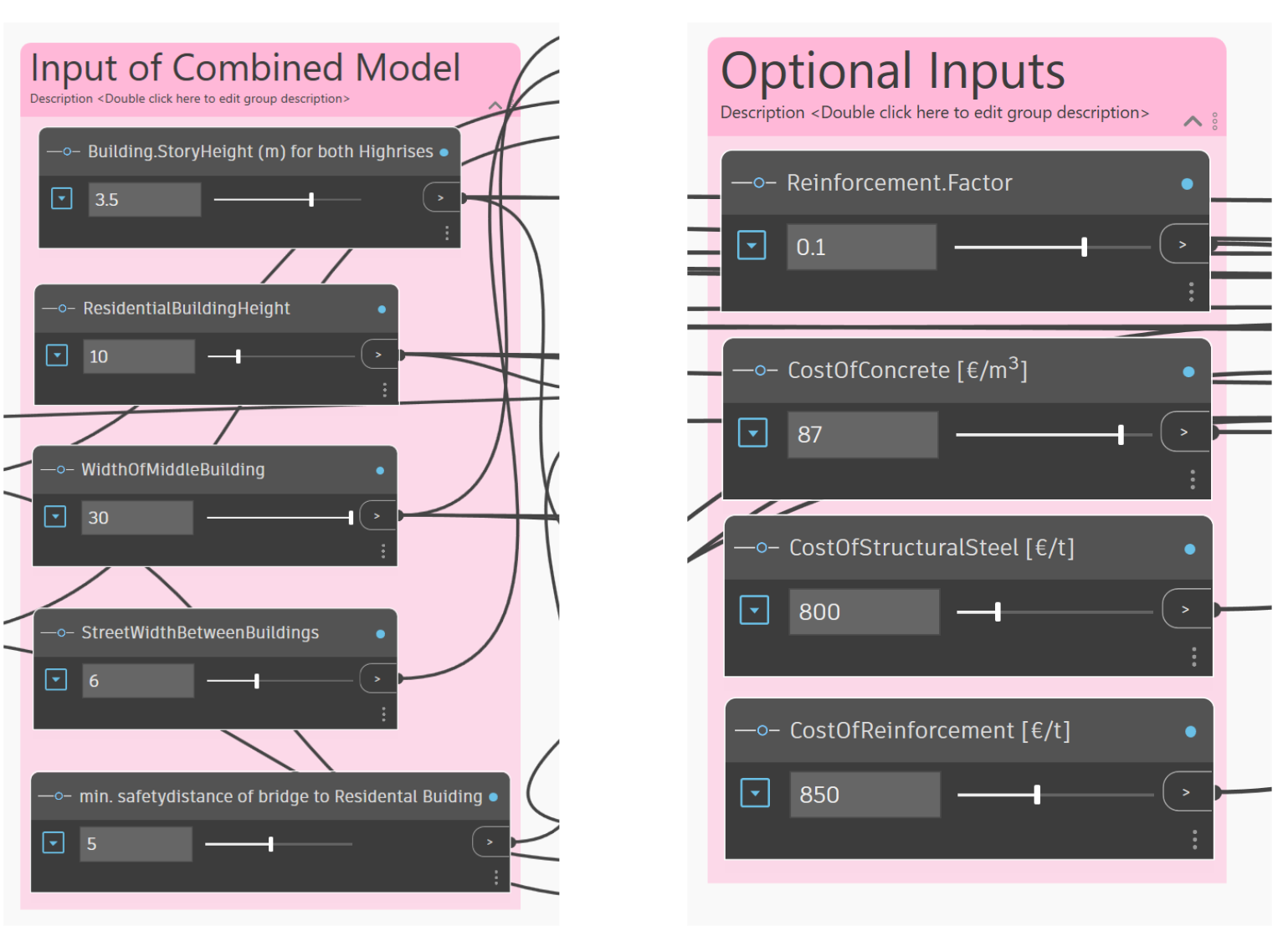

Inputs and Outputs

The newly introduced inputs include:

- The floor height of the two high-rises.

- The height and width of the residential building.

- The minimum safety distance between the bridge and the residential building.

- The street width between the buildings.

Additionally, for material quantity and cost calculations, the following inputs were defined:

- Reinforcement ratio of the framed tube structure.

- Material costs (adjustable to reflect current market conditions or project-specific requirements).

The material costs consist of:

- Cost of concrete per m³.

- Cost of structural steel per ton.

- Cost of reinforcement per ton.

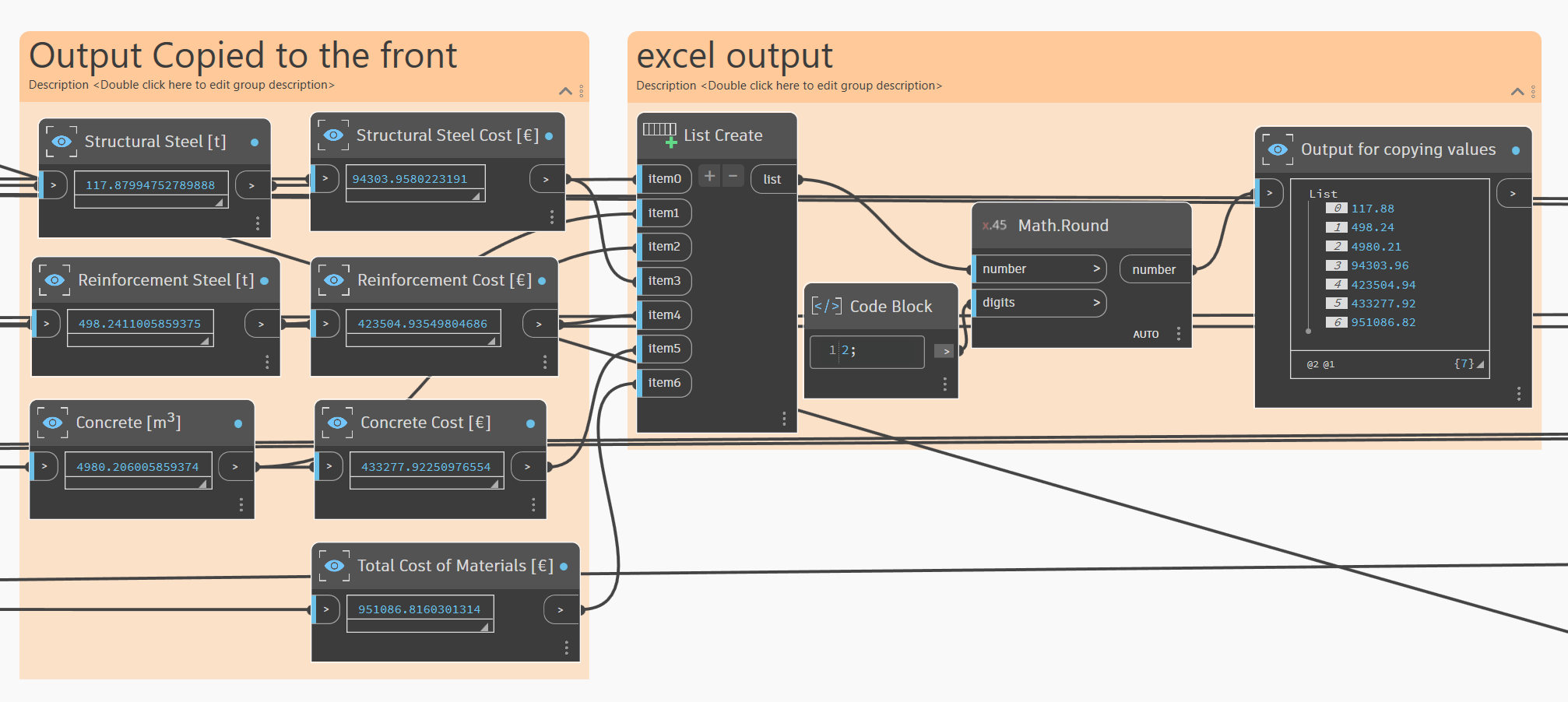

The high-performance criteria include:

- Tonnage and cost of structural steel.

- Tonnage and cost of reinforcement.

- Volume and cost of concrete.

- Total material costs (limited to the materials mentioned above).

Model Adjustments

The truss bridges dimensions were resized to function as a pedestrian bridge. Its start and end points depend on the distance between the high-rises, the height of the residential building, the chosen safety distance, and the floor height. The bridge always maintains the minimum safety clearance above the residential building and aligns with the nearest upper floor level of the high-rises to ensure pedestrian accessibility.

The geometric positioning of the two high-rises depends on the width of the residential building and the defined street width. All three buildings were enhanced with quantity calculations for the framed tube structure, enabling the aggregation of material quantities across the four models and the evaluation of the building complex as a whole.

In summary, the high-rises and the pedestrian bridge dynamically adapt to the dimensions of the residential building.

Design Alternatives

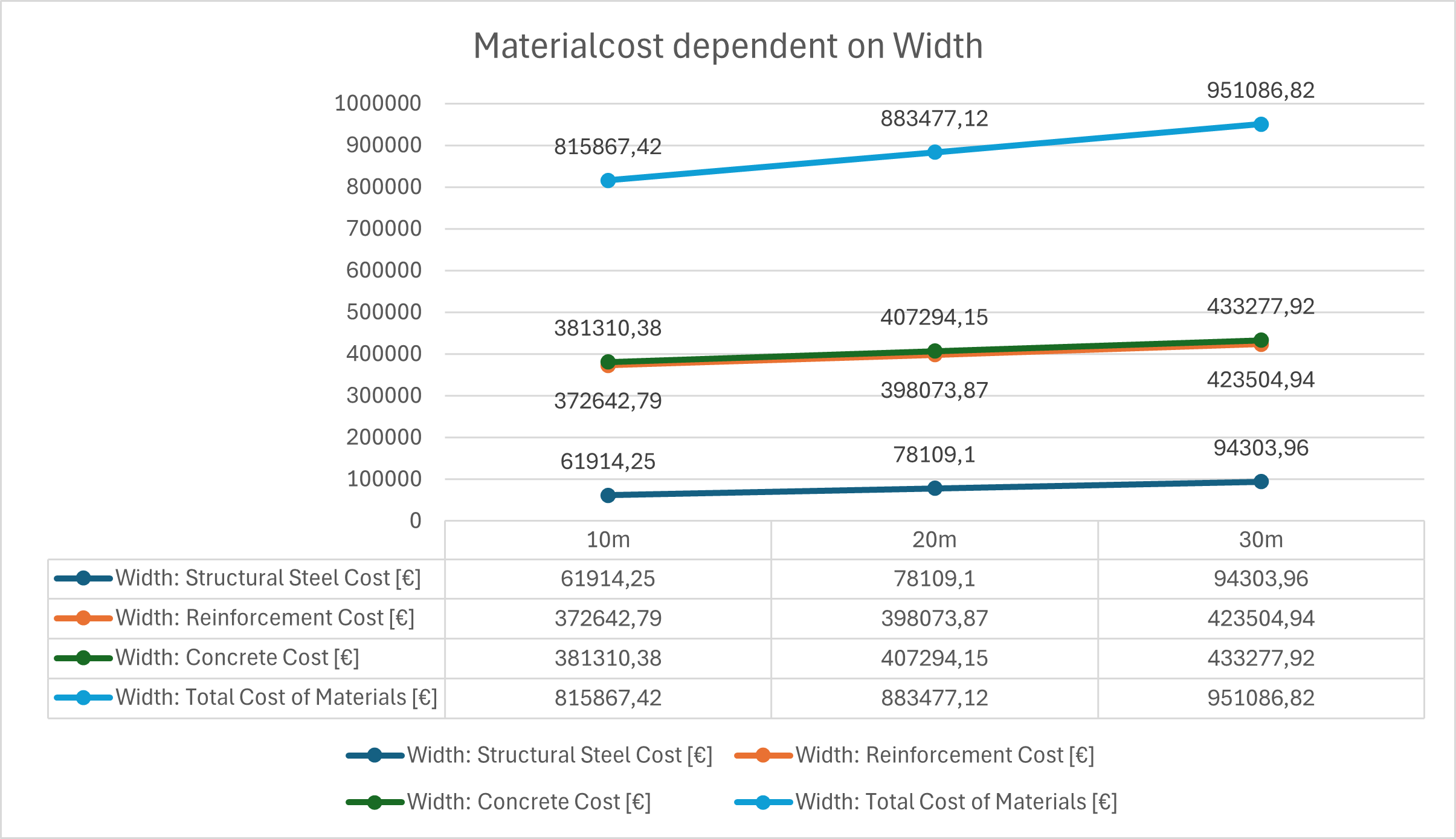

For the comparative analysis, five predefined input configurations were established for the residential building, as shown below:

| Variants | 1 | 2 | 3 | 4 | 5 |

| Height [m] | 10 | 10 | 10 | 20 | 30 |

| Width [m] | 30 | 20 | 10 | 10 | 10 |

The three design variants were selected —Variant 1, Variant 3, and Variant 5—and visualized below using interactive sketchfab 3D models. These visualizations provide a geometric representation of the building complex, including the pedestrian bridge and the spatial relationships between the high-rises and the residential building.It is important to note that the framed tube structure was not geometrically applied to the two additional buildings (the high-rise and the residential building) in the visualizations. Instead, its application was limited to the calculation of material quantities and costs. This means that while the structural analysis and material estimations for the framed tube system were incorporated into the overall model, the geometric representation of the buildings in the visualizations does not explicitly reflect this structural system.

Variant 1:

This variant features a residential building with a height of 10 meters and a width of 30 meters.

Variant 3:

In this variant, the residential building has a height of 10 meters and a width of 10 meters.

Variant 5:

This variant showcases a residential building with a height of 30 meters and a width of 10 meters.

The goal of this analysis is to compare the costs of the building complex and determine whether it is more economical to build the central residential building taller or wider. The following parameters were held constant across all variants to ensure comparability:

- Reinforcement factor: 10%

- Cost of concrete: €87/m³

- Cost of structural steel: €800/ton

- Cost of reinforcement: €850/ton

- Floor height of high-rises: 3.5 m

- Street width between buildings: 6 m

- Minimum safety distance of the bridge: 5 m

Results and Discussion

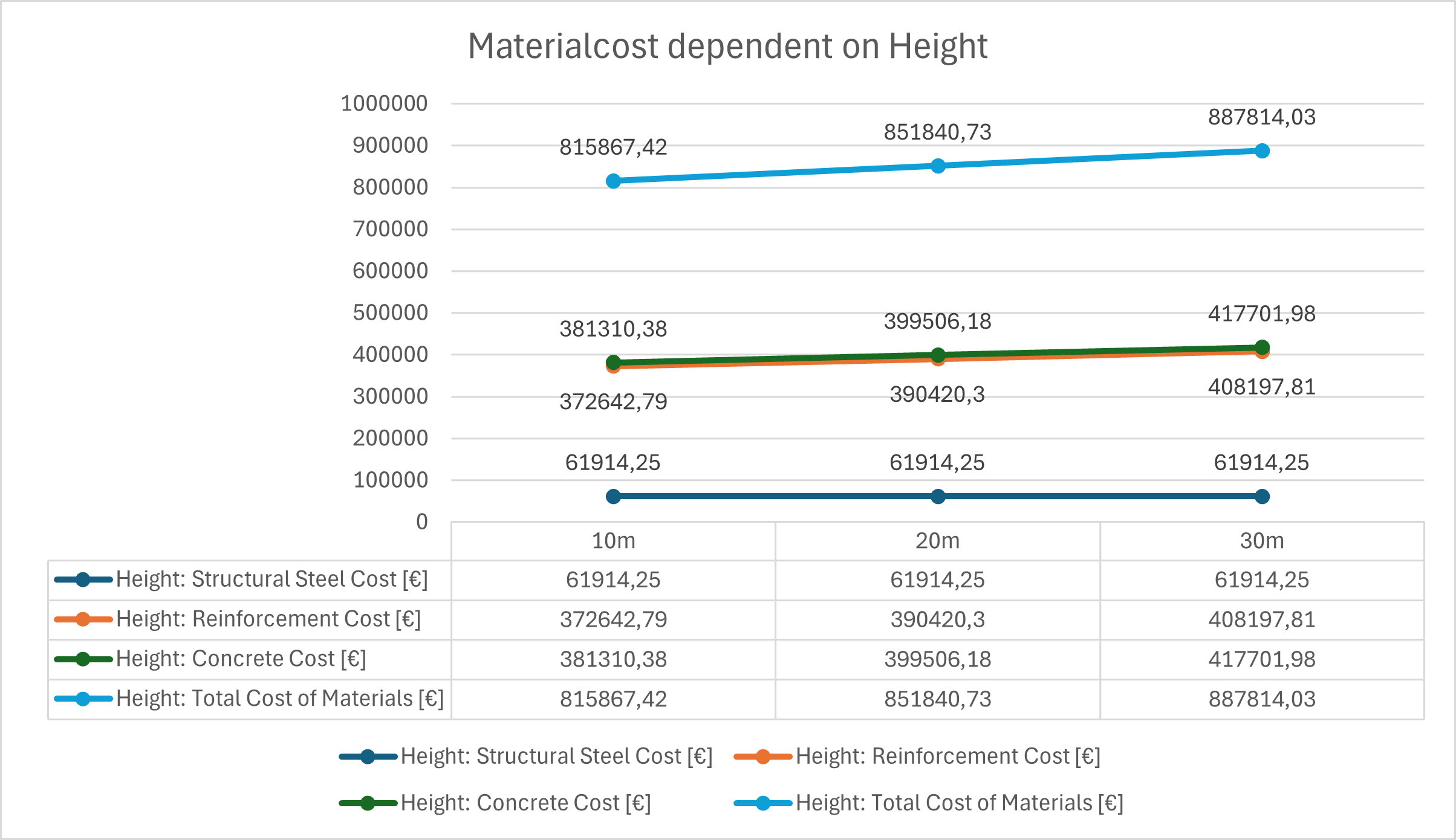

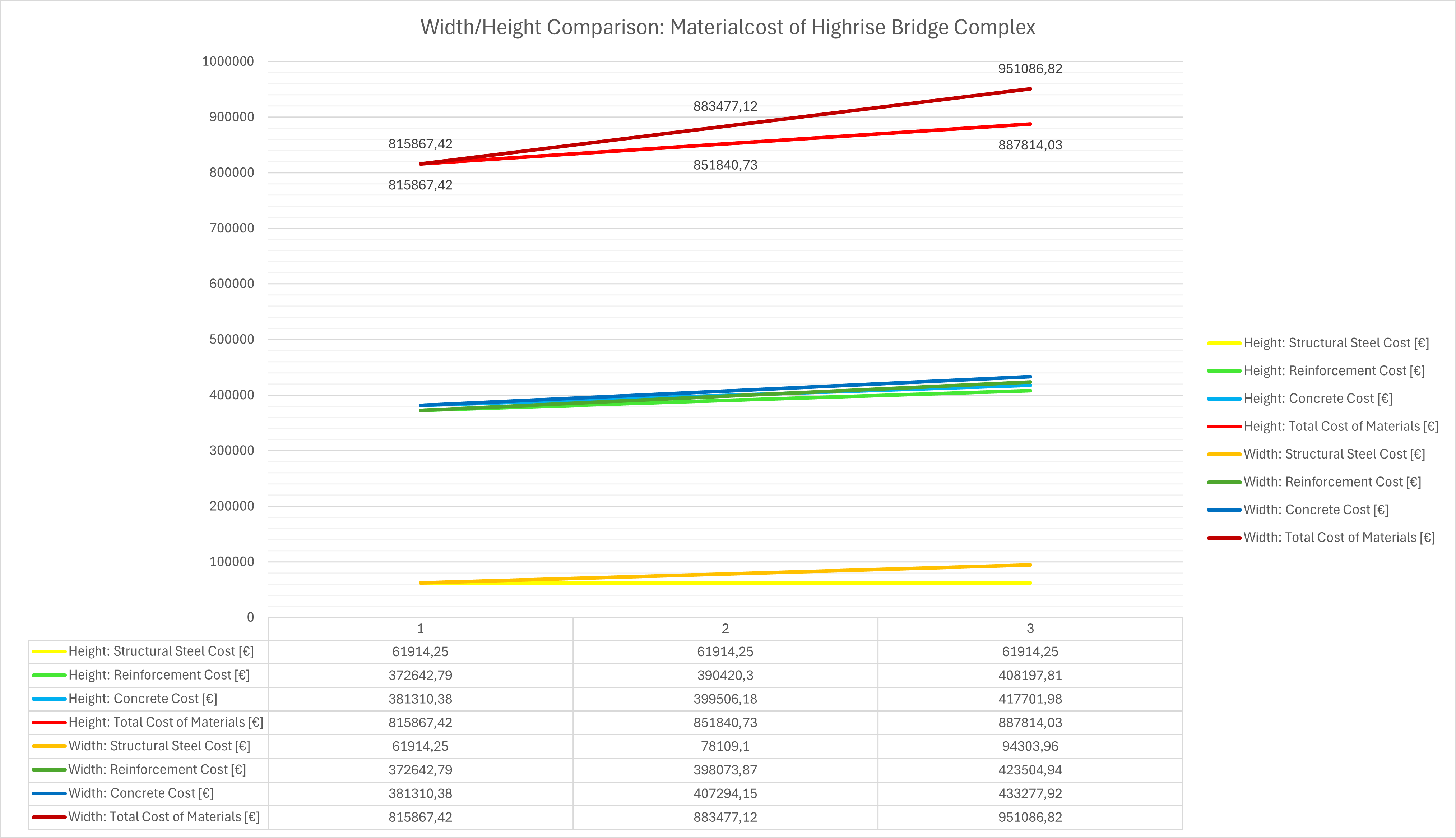

The material quantities and costs were calculated for each variant, and the results were visualized in graphs. The following graphs illustrate cost changes in 10-meter increments, comparing height and width variations.

To empasize the comparison of building taller or wider the following combined graph was created. Light colors represent width expansions, while dark colors represent height increases. The color coding is as follows:

- Yellow: Structural steel

- Blue: Concrete

- Green: Reinforcement

- Red: Total costs

The analysis reveals that widening the residential building leads to a more significant cost increase (7.4%) compared to increasing its height (4.1%). This is logical, as widening the building requires a longer bridge, increasing material demands. Concrete and reinforcement costs rise more with width expansion due to the relationship between column and beam lengths in the framed tube structure. Structural steel costs remain constant for height variations, as the bridge length remains unchanged, but increase with width expansion due to the greater span.

Summary

In conclusion we can say that the integrated parametric model successfully demonstrates the viability of connecting two high-rises with a pedestrian bridge over a residential building while providing detailed material and cost analyses. The project highlights the economic advantages of vertical expansion over horizontal expansion for the central residential building. This developed tool can be useful for urban planners and architects, enabling data-driven decision-making in the design of a complex urban system.

Downloadable Content

Download Combined Parametric Model