Introduction

Highway pavements are an integral part of this roadway network. Pavements provide a smooth and durable all-weather traveling surface that benefits a range of vehicles (cars, trucks, buses, bicycles). During passing time, different types of damages are caused to the components of highway pavement which leads to deterioration of the pavement. In the intricate domain of civil engineering, the choices made during the design phase of highway pavements reverberate through the entire life cycle of these critical infrastructural elements. The longevity and functionality of flexible pavements hinge not only on their initial construction but equally on the nuanced decisions made during the design process where sustainability stands as an ever-prominent goal.

Design Options

The assessment focuses on the decision-making, engineers have to take when designing the base-course of the highway pavement. The best design option for the designed base-course of highway pavement is as follows:

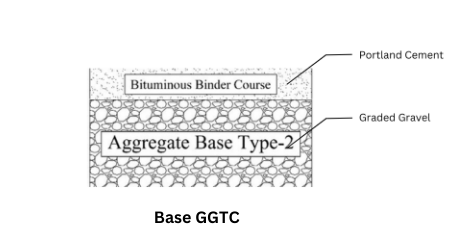

- Base GGTC (Graded Gravel Treated with Cement)

| Design Option | Binder Material | Coarse Aggregates | Fine Aggregates |

| Base GGTC | Portland Cement | Graded gravel | – |

Life Cycle Inventory

The following table represents the composition of different materials used for the design option. For each material, quantity of energy consumption for extraction, production and construction (MJ/t) and emission of greenhouse gases CO2, N2O, CH4 (kg/m3) is collected.

| Material | Scope | Quantities | Energy | CO2 | NOx | SO2 |

| Portland Cement | Base GGTC | 12% | 5161 | 0.904 | 0.177 | 0.065 |

| Graded Gravel | Base GGTC | 890 | 88 | 0.0013 | 0.0018 | 0.0026 |

The “quantities” column has two different meanings, depending on materials. For binders, the values represent the percentage used in 1 cubic meter of course whereas, for others it represents the quantities in Kg of materials consumed to produce 1 cubic meter of the specific course.

Life-Cycle Timeline

The interventions for the maintenance are as follows;

| Design Option | Event | Frequency | Total Lifespan |

| Base GGTC | Routine Maintenance | 20 | 20 |

| Base GGTC | Resurfacing | 2 | 20 |

| Base GGTC | Major repairs | 2 | 20 |

The duration of the interventions in terms of days;

events.Op1.Pavement <- c(RM.p = 20, R.p = 2, MR.p = 2, END = lifetime)

Routine Maintenance: Routine maintenance activities typically include activities like cleaning, inspection, minor repairs, and preventive measures.

Resurfacing: Resurfacing involves applying a new layer of asphalt over the existing pavement to restore its smoothness and ride quality.

Major Repairs: Major repairs involve significant interventions to address extensive pavement damage, such as large cracks, potholes, or structural deficiencies.