1. Introduction

This assignment aims to conduct a life-cycle analysis of a tower of a wind turbine

as well as a multi-criteria decision-making analysis.

2. Civil engineering sub-system/ design options

As a sub-system, the type of installation or the pipes/protective tubes and the buried expansion are

considered and analysed in this work. The fibre optic cables are laid underground throughout

Germany. The fibre optic cables transmit the light pulses to the receiver and must be protected from

external influences by protective pipes.

In order to determine the required materials for the cable protection tubes, the following

parameters must be taken into account:

o Length of the buried fibre optic cable

o Length of the protective tubes

o Stiffness

o Material used

o Transport and installation options

To calculate the amount of material required, the length of the fibre optic cables to be laid and the

stiffness of the tubes are decisive.

There are not many options for protecting or laying the fibre optic cables. Plastic pipes are often used

as the material, which are then laid in a trench, see figure 2. Furthermore, fibre optic cables can be

integrated into sewage pipes, whose protective pipe is the surrounding concrete, see figure 1, and

fibre optic cables can also be routed along wooden poles, which consist of metal-free air suspension

cables (ADSS cable = All Dielectric Self Supporting), see figure 3

3. LCA

3.1 Goal and scope

GOAL:

This life-cycle assessment examines three design options of fibre optic cable laying and therefore

identifies their events and inventory throughout their life-cycles. In addition, specific aspects of the

impact of the installation variants are chosen and analyzed. The aim is to obtain information on the

environmental impact of the various design options with regard to different inputs. Furthermore, the

best installation option based on the defined inputs is to be crystallized based on this study. This

study will be conducted only for academic learning purposes and thus making them comparable. The

scope of this assignment will therefore be limited to the set of tasks which were required and targets

students and teacher. As the background research and conducted data was simplified, this paper

doesn’t claim completeness or intends public assertions.

SCOPE:

Product function: The task of the chosen installation method is the fast, direct and safe way of

storing the fibre optics. The selected installation method protects the fibre optic cable from external

damage and is intended to provide a fast connection of the fibre optic cable from the main centre to

the house or distributor.

Functional unit: The functional unit of a tower can be defined as the number of years in operation. In

this way, one can compare the different types of installation and compare the results with other

studies.

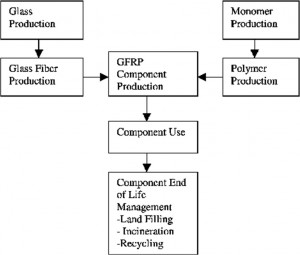

System boundary: A simple product tree of a fibre optic network is shown in figure 3.

Figure 3: product tree of fibre optic systems

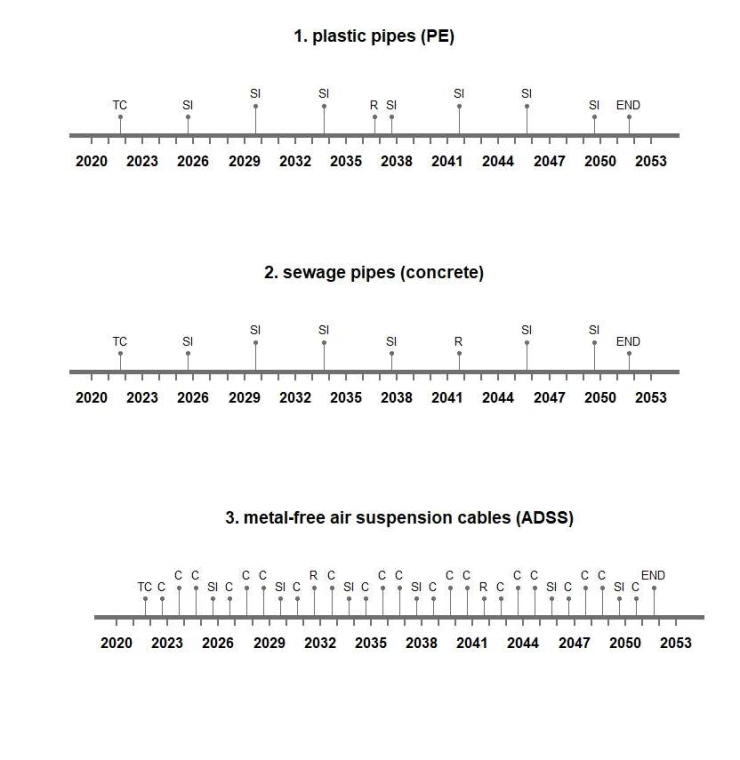

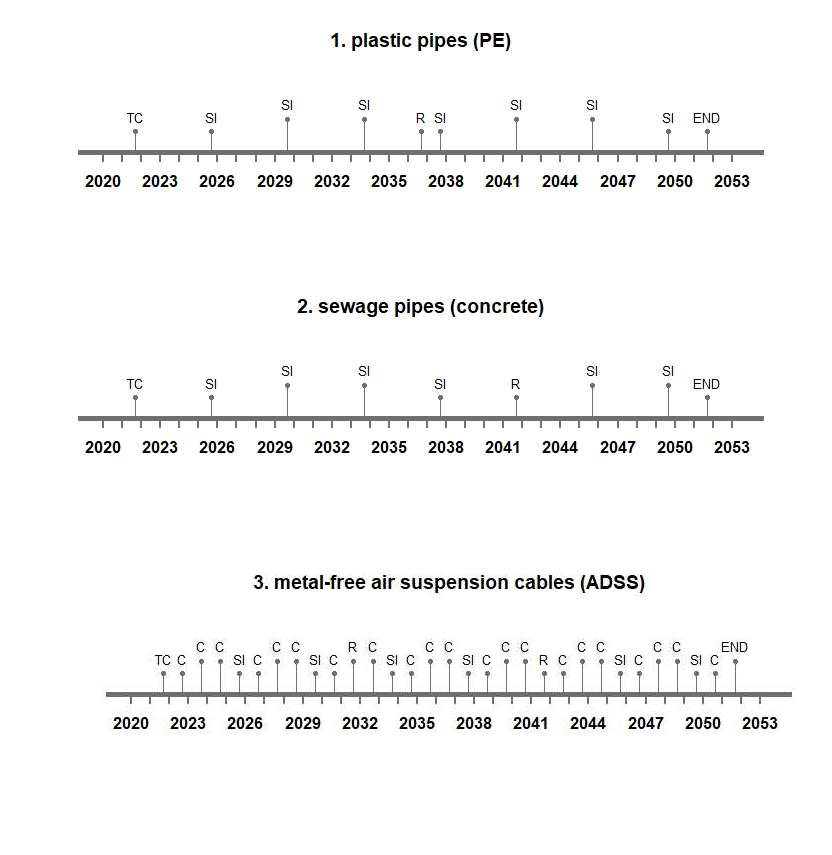

3.2 Life- Cycle Time Span

It is unusual for glass fibre networks to change the type of installation or to replace the protective

pipes in which they are installed. Therefore, no maintenance work is foreseen for fibre optic

networks. Maintenance work only takes place for data transmission by Telekom, which tends to be

active at night, so that users do not notice it. This view excludes catastrophic events where cables

and protective pipes have to be patched. Therefore, in this work, rather smaller maintenance events

such as cleaning of the suspended cables, stability checks or replacement of patches/connectors are

considered. All these measures require only a very small amount of material, as the patches, for

example, are relatively small as a component. The most important inspected interventions that an

installer has to consider when maintaining the net are shown in Table 1. As can be seen, no cleaning

work is carried out for the buried protective cables and the waste water pipes. Here, it is hardly

possible to carry out annual maintenance because of the high costs involved when excavation work

has to be carried out. Furthermore, the cables inside the concrete sewage pipes are also difficult to

maintain, as the necessary expensive construction clearance has to be created here as well. We

therefore assume zero years for the cleaning work in options 1 and 2.

3.3 Life- Cycle Inventory

The installation variants examined here consist of three different materials: PE-HD, concrete and

metal-free PE. The following amounts were determined by research for the installation of 100 m of

fibre optic cable:

Option 1: empty conduit cable (PE-HD) 119 kg

Option 2: sewage pipes (integrated in concrete pipes) 252000 kg

Option 3: Suspended cables (“ADSS- all dielectric self- supporting”) 26 kg

This results in further figures for energy consumption, CO2 emissions and the glass fibres to be laid

for the production of the various cables. These are presented in the table, which shows the

quantities of materials used during the entire life cycle of the glass fibre network. Since the research

provided little information about the ADSS cables, assumptions were made here. The values for the

PE plastic cables were used for the ADSS cables. Furthermore, it should be noted here that it is

assumed that fewer pipes can be installed in the sewage concrete pipes and above ground (on the

wooden poles) due to the lack of space. The amounts are also shown in figure 5.

4. Multi- Criteria Decision Analysis

The multicriteria decision analysis was carried out using a TOPSIS analysis in Rstudio. The indicators

weight and glass fibre were weighted with 0.1, while energy and CO2 were weighted with 0.4. The

latter two indicators are considered “more important” for the environment. Although energy and

CO2 are to some extent interdependent, they were ranked higher because glass fibre is often

recycled and reused in the construction industry, for example. The recycled plastic is installed in

sewage pipes or wind turbines.

It is clear that in TOPSIS 1, design option 2 is ranked as the best option with 43.78%, which is due to the low values for energy and

CO2 consumption. Option 1 scores just below option 3 grade 28.07%. We also see that the values are very close, which is due to the

missing information for the ADSS cables. Once the positive and negative ideal solutions are included in the analysis, we see

that the options are ranked relatively equally. In the objective comparison, the TOPSIS 1 analysis makes more sense as option 1 has the worst scores in 3 out of 4 categories and should therefore not be considered equivalent to option 3. As a

conclusion, the positive and negative numbers for the ideal solution should be improved to get a

more accurate result of this analysis.

5. Discussion

Regarding the trade-offs made in this task, the most important is the limited choice of impact or

consumption categories. Only a small range was analysed, while other equally important figures

could not be proposed. Other impacts were not taken into account, for example the construction

work for laying or the execution work for creating the wooden masts. Here, further emissions are

emitted and transport also plays an important role in the costs of the laying work.

On the same hand, the choice of categories was very varied, so that different aspects could influence

the results. Resuming to this, further approaches could concentrate more on a specific field, for

example only the gas emissions during the life cycle.

In addition, the influence of the plastic cables on the CO2 balance is higher than that of the concrete,

which leads to a worse CO2 balance at the time of construction. However, it must be taken into

account that laying plastic pipes can last up to 30 years, so the carbon footprints can balance out

after the lifetime of the cables. To obtain more accurate results, different life spans should be

considered.

6. Sources

https://docplayer.org/6202540-Alho-architektur-die-vielfalt-des-modularen-raums.html

https://www.researchgate.net/figure/Life-cycle-environmental-impacts-from-production-of-glassfiber-

china-reed-fiber-Epoxy_tbl2_222403148

https://community.fs.com/de/blog/tips-for-using-and-maintaining-fiber-patch-cables.html

https://www.schoengen.de/fileadmin/website/download/prospekte/pdf/2_1_Schutzrohre_PEHD_

Stangenware_2016_A4_oP.pdf

https://www.rinninger.de/index.php/rohre-titel/betonrohre-kreisrund

https://www.rehau.com/downloads/510054/katalog-rehau-telekommunikation.pdf

https://www.fbsrohre.de/fileadmin/content/shop/nachhaltigkeit/fbs-expertise-oekologie.pdf

https://www.oeko.de/fileadmin/oekodoc/Digitaler-CO2-Fussabdruck.pdf

https://www.deutschlandfunk.de/recycling-von-glasfaser-kunststoff-aus-windkraftraedern-100.html