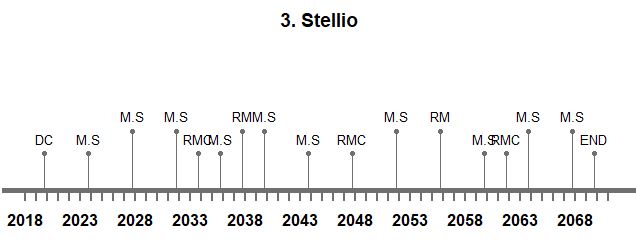

As a first step, the timeline model was defined as a function including the lifetime, the occurring maintenance events as well as their frequency and duration. All events were combined in one list. The choice of a common lifetime was problematic since each system has its own lifetime depending on technical and environmental conditions. The lifetime of 50 years was set for all systems. For the Xpelair, with a lifetime of 5 years, conversions needed to be done to meet the compromise. Thus, the interventions were multiplied by the factor 10 in order to keep the calculation with a linear approximation simple.

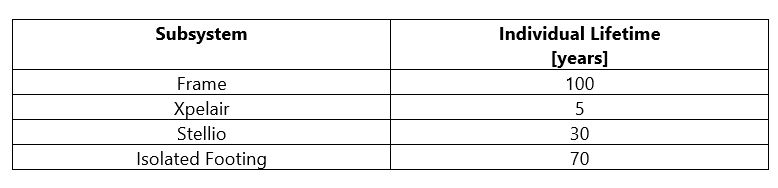

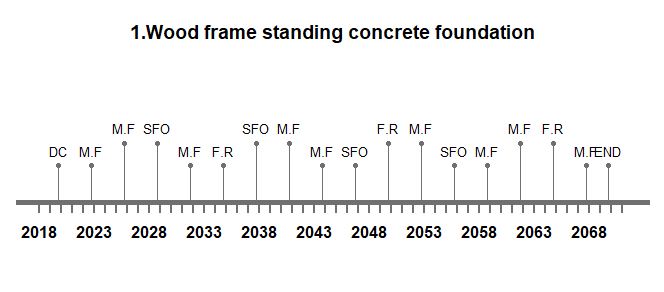

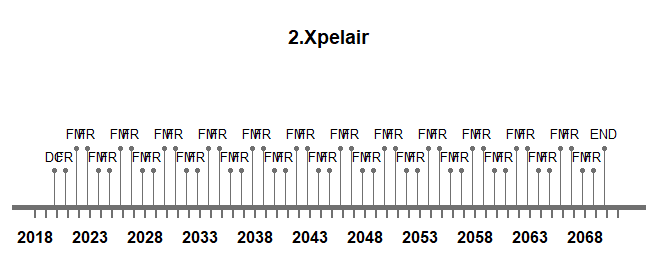

Subsequently, an iteration was implemented to include all possible scenarios between the systems, with a total of 15 combinations. After setting the start date and the lifetime, each event as well as its frequency and duration were implemented for the four individual systems. The following events were defined and visualized by a timeline for each subsystem:

- Replacement of the shallow Frame overlay (SFO)

- General maintenance of the Frame (M.F)

- Frame Replacement (F.R)

- Filter replacement (FR)

- Filter maintenance (FM)

- Maintenance of the Stellio (M.S) including inspections and service

- Replacement of Mirrors (RM) caused by natural causes

- Replacement motion and control systems (RMC) caused by environmental impacts

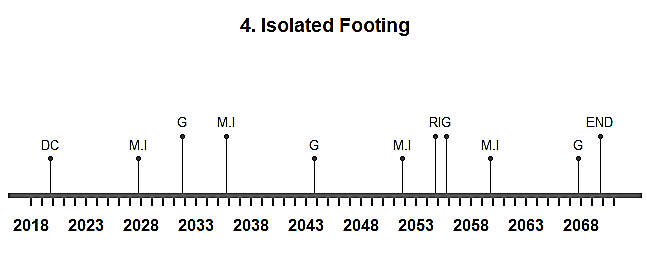

- Maintenance (M.I) such as plastering or painting

- Grouting (G) to stabilize the soil or fill any cracks

- Replacement of the Isolated Footing (R.I) due to deterioration from ground water or other factors

Page Navigation

2.1 Maintenance Strategy of Individual Systems

2.2 Integrated Maintenance Strategy

3. Life-Cycle Inventory Analysis