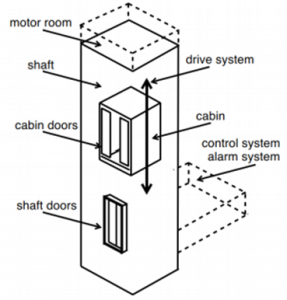

Despite the global push towards green buildings, the environmental impact of elevators is often neglected. In The present project the environmental impact of elevators is assessed by performing a life-cycle analysis (LCA). The objective of this study is to determine the environmental impact of elevator design options. The results help reduce the emissions of using the building. That creates added value for the asset management and the environment. The study is comparative and helps improve decisions. An elevator and its function are defined as a “transport device that is used to move people or goods in vertical direction”. Possible functional units are weight and passenger capacity, height, speed, and size.

In this project, the life time of the shopping center was determined to 50 years. Elevators have a product lifetime of 15 to 30 years. Continuous maintenance activities are needed to ensure the safety and continued performance, cleanliness and cosmetic appearance of an elevator. There are two types of elevator maintenance strategies: corrective (reactive/breakdown) maintenance includes repairs after failure and preventive maintenance includes maintenance, repair, and replacement for avoiding failure (time-based /condition-based). Both maintenance strategies and inspection intervals are combined. Corrective maintenance can be included in the life-cycle timeline by scheduling interventions. The system lifetime assumed in this project is 25 years accordingly. Time-based preventive maintenance is based on a predetermined maintenance schedule.

LCA for one specific elevator is studied further. The detailed calculations of material quantities and emissions, however, can be included as a baseline into the LCA. The environmental impact of an elevator, resembling design options, is assessed according to the ISO 14040 standards. The results are relevant for a comparison to the different design options. The analysis relies on the product life-cycle. During the period of use, emissions for a lifetime of 25 years are assessed using electricity data published by the OECD. Maintenance work also including replacement of the ropes after 10 years, is considered but not further detailed. Modernization is kept out to keep the LCA simple. Emissions for the end-of-life treatment result mainly from 45% of the material weight, which requires multimetal separation.

For more insight of the project different civil engineering systems within the Integration context are followed; Climate envelope (focus on girders), a External thermal insulation composite system and a Wet sprinkler system. All of these products are incorporated in overall Integrated maintenance planning and are beeing assessed to define the impact of the integration on Integrated life-cycle analysis by a Integrated maintenance plan by multi-objective optimization.

References

-

Yamashina, Hajime, and Shunsuke Otani. 2001. “Cost-Optimized Maintenance of the Elevator -Single Unit Case.” In Journal of Quality in Maintenance Engineering, 49–70. Vol. 7, No. 1. MCB University Press.

-

Zhang, Jian, Xianli Zhao, Canmian Liu, and Wei Wang. 2018. “Reliability Evolution of Elevators Based on the Rough Set and the Improved TOPSIS Method.” Mathematical Problems in Engineering2018 (July): 1–8. https://doi.org/10.1155/2018/4784965.

-

Stepanov, Michail, Batraz Kaytukov, and Ayub Mechiev. 2018. “Reliability and Safety of Vertical Transportation Use.” Edited by A. Volkov, A. Pustovgar, and A. Adamtsevich. MATEC Web of Conferences251: 03013. https://doi.org/10.1051/matecconf/201825103013

-

Lai, Chia Tai Angus, Wei Jiang, and Paul R. Jackson. 2019. “Internet of Things Enabling Condition-Based Maintenance in Elevators Service.” Journal of Quality in Maintenance Engineering25 (4): 563–88. https://doi.org/10.1108/JQME-06-2018-0049.

-

Park, Seung-Tae, and Bo-Suk Yang. 2010. “An Implementation of Risk-Based Inspection for Elevator Maintenance.” Journal of Mechanical Science and Technology24 (12): 2367–76. https://doi.org/10.1007/s12206-010-1004-1.

Navigation