A factory is a bustling and dynamic workspace, meticulously designed to optimize productivity and efficiency in industrial operations. When constructing a factory, ensuring the safety and longevity of the structure is paramount to safeguard the well-being of the employees who will spend countless hours within its walls. When integrating complex civil engineering systems, it’s crucial to consider factors such as deterioration and failure rates in the Life-Cycle Assessment. Sustainability of the integrated structure, future maintenance scenarios, and risk assessments should also be considered when evaluating the overall viability of the system.

In this assignment, we analyze the systems, their respective components, and explore the optimal design options for each.

| System | Component | Best design option |

| Steel-structured factory | Roof purlins | Hot-dip galvanized steel |

| Private concrete villa | Slab | GGBS-RC |

| Frame structured building | Beam | GGBS-RC |

| Pile foundation | concrete pile | Ready mix 1 |

| Rail way system | Railway Track | PRC + steel + ballast |

Integration Context

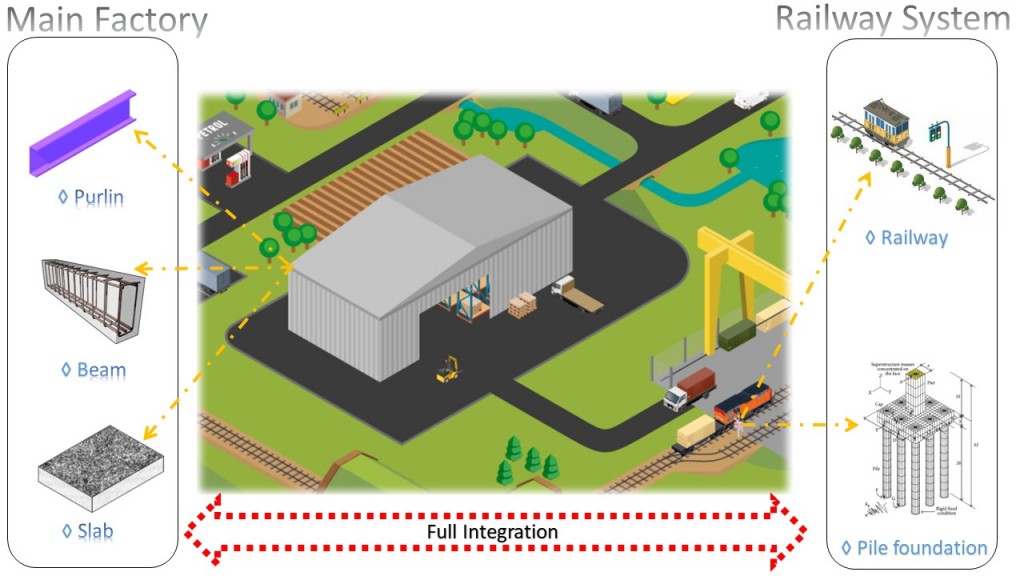

The integration context revolves around a composite factory that consists of concrete beams and utilizes a mezzanine floor constructed from concrete slabs, the roof is formed of steel purlins to support the roof coverings. A composite factory allows for versatile design options, blending the aesthetic appeal of steel with the functionality and durability of concrete. This flexibility in design can cater to various architectural styles and functional requirements.

This factory is located adjacent to a railway line, which serves as a crucial transportation link for the goods manufactured within the facility. The railway line runs on a bridge that requires a sturdy bridge foundation for support and stability.

We will utilize the identical concrete material for both beams and slabs, but it will be different in the piles.

Interdependencies and Reliability

The reliability of each system is interdependent on the others within the integration context. For example:

• The reliability of the concrete beam and slab affects the structural integrity of the factory building, which in turn influences the stability of the roof steel purlins.

• The structural integrity of roof purlins can have a significant impact on the structural integrity of concrete slabs and beams in a factory. Roof purlins help distribute the weight of the roof evenly across the supporting structure, including the concrete slabs and beams. If the purlins fail, the load distribution may become uneven, placing excessive stress on certain areas of the slabs and beams, potentially leading to cracking or failure.

• The reliability of the railway system depends on the bridge foundation’s stability, as any issues with the foundation could disrupt the railway tracks and impede transportation.

Conversely, failures or deficiencies in any of the systems could cascade and impact the reliability of the entire integration context. For instance:

• Structural failure in the concrete beams or slabs could compromise the integrity of the factory building, potentially leading to disrupting production activities.

• Similarly, if the bridge foundation experiences issues, such as settlement or structural weakness, it could affect the stability of the railway tracks, causing disruptions in transportation and impacting the supply chain.

In Figure 1, the integration of these diverse systems results in a cohesive and efficient operational environment across the board.

Figure 1. Integrated System and it’s Subdivision in Subsystems.