Home / Group 2 / Integration Context of the Civil Systems / Tunnel

Engineering Aspects of Tunnel Life cycle

Tunnels are a vital link in transport networks which represent a significant investment in all life cycle phases from planning, investigation works, construction and operation. Decisions through the whole life cycle of a tunnel should be based on solid facts and reliable data especially in the context of considerable impacts on both the environment and society. The calculation of total life time costs for different design alternatives, maintenance options and societal impacts can be used to compare different technical solutions and select the optimal design and maintenance alternative. Generally, problems related to tunnel degradation can be divided into those caused by external pressure and those caused by the deterioration of materials. These problems are gradually increased through all life cycle stages of a concrete structure such as a tunnel, therefore decisions about the timing and the type of maintenance should be based on degradation prediction models and monitoring of the structure performance or degradation processes. Uncertainties in the decision-making process can be decreased by using information from monitoring which are used to establish triggering thresholds for the structure passing certain performance levels. The current study emphasizes on influence of tunnel components and materials on concentration levels of environmental indicators.

Goal and Scope of Assessment

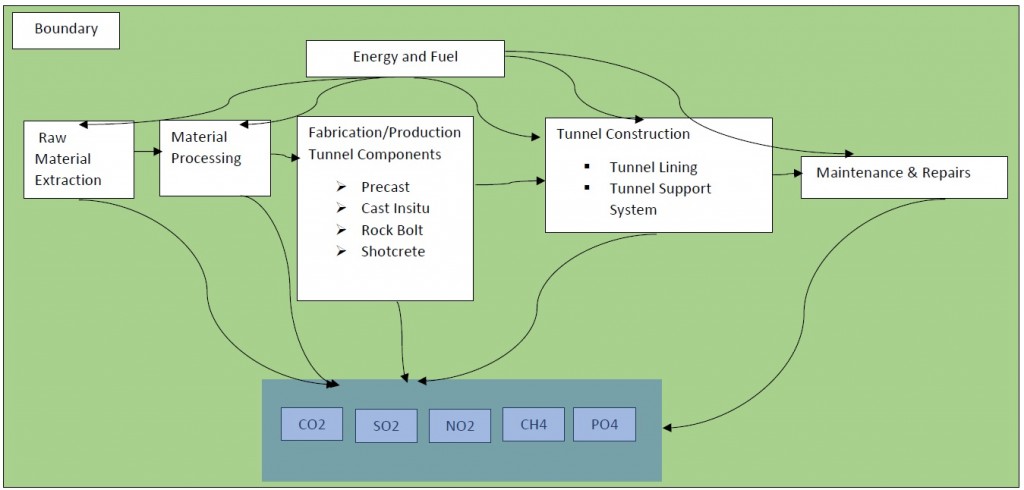

This part highlights the lifecycle and carbon footprint of tunnels, which are usually seen in real-life globally. The indepth insight incites the systems thinking consideration of tackling gaseous emissions. The study of Life cycle analysis of tunnels can be indicative reference for revolutionising design, construction and maintenance to achieve the sustainability of tunnel infrastructures. Global warming is a critical issue nowadays. Although the tunnel system is considered as green transportation, it cannot be denied that tunnels have a significant environmental impact during construction and maintenance. The main goal of this is to study about influence of tunnel system on global warming. Along with it Acidification and Eutrophication indicators are also studied and analyzed. The scope and the boundaries of the assessment are presented in the figure below.

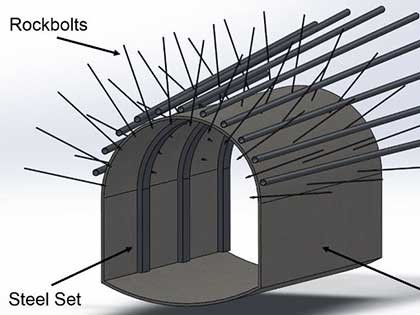

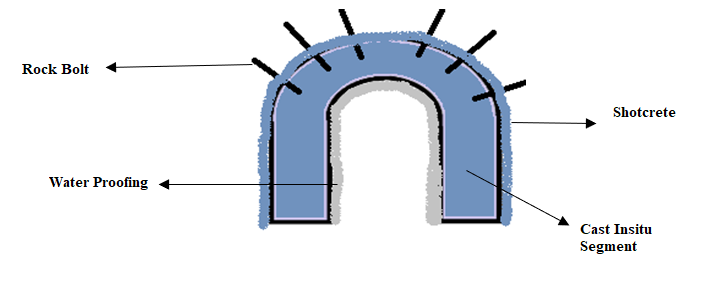

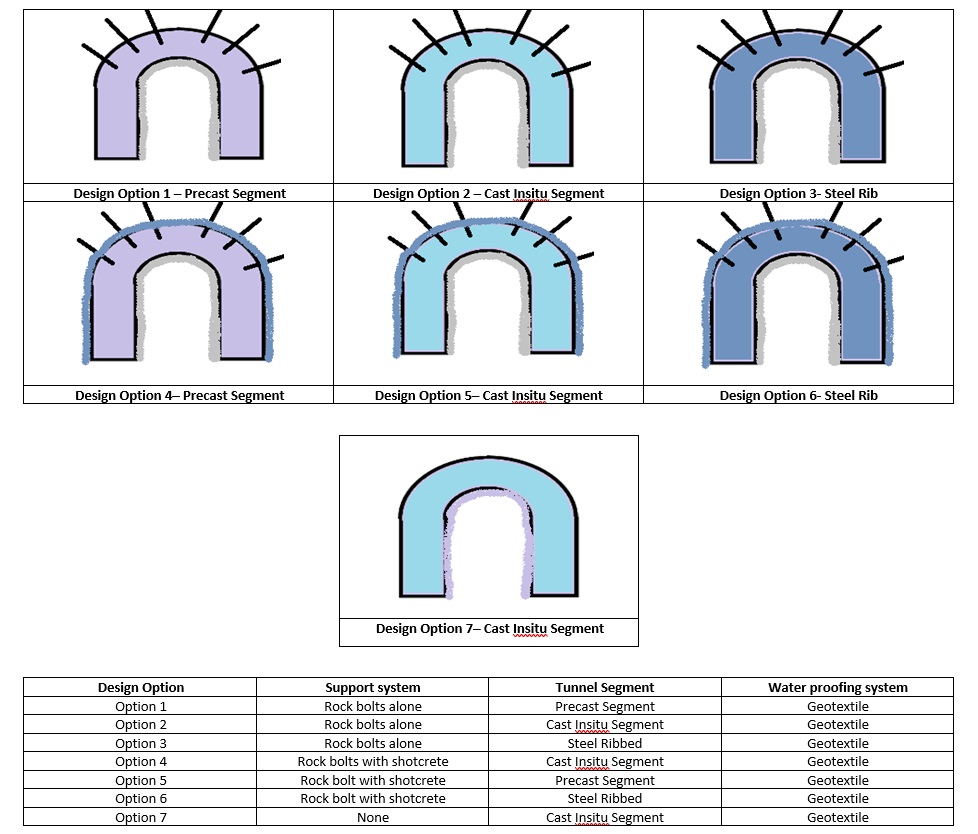

In order to study the influence of tunneling materials on environmental indicators, various tunnel designs are considered. Tunnel design takes into account wide range of materials for construction purposes, since there are different types of tunnels based on ground conditions, materials used and also based on shape. For the current study three types of tunnel segment are considered as one subsystem of tunnel : – Precast, cast insitu and steel ribbed tunnel. Second subsystem taken into account is support system: – rockbolt alone and rockbolt with shotcrete. As third constant subsystem water proof geopolymer is considered.

For the analysis of environmental indicator seven design options are considered by varying the subsystems options like as Design option 1: – Lining considered is Precast with support system taken as rockbolt and geopolymer water proofing.

Further design alternatives are presented in the figure & description in table below.

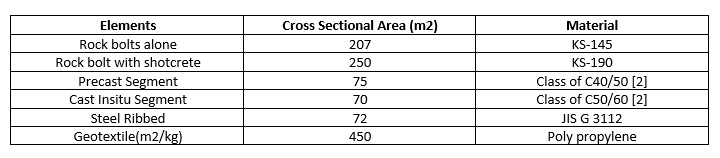

The table below present the materials used in this study for different elements under analysis along with their dimensional area and material specification.

Life Cycle Inventory of different materials, Performance and environmental indicators

For the construction of tunnel segment, support system and water proofing system various materials are used. The table with the quantities of each materials along with the amount of energy liberated as part of production mechanism and various gaseous emissions associated with extraction, processing, manufacturing, production of each material were created and fed into R software for complete analysis. The scope defines the system that each material is associated with like PCS – Precast Concrete Segment, CIS – Cast Insitu Segment, RB -Rock bolt, RBS – Rockbolt with shotcrete. Based on information obtained from various journals the values for environmental indicators are considered for tunnel construction impact studies on environment.

Life-Cycle timeline

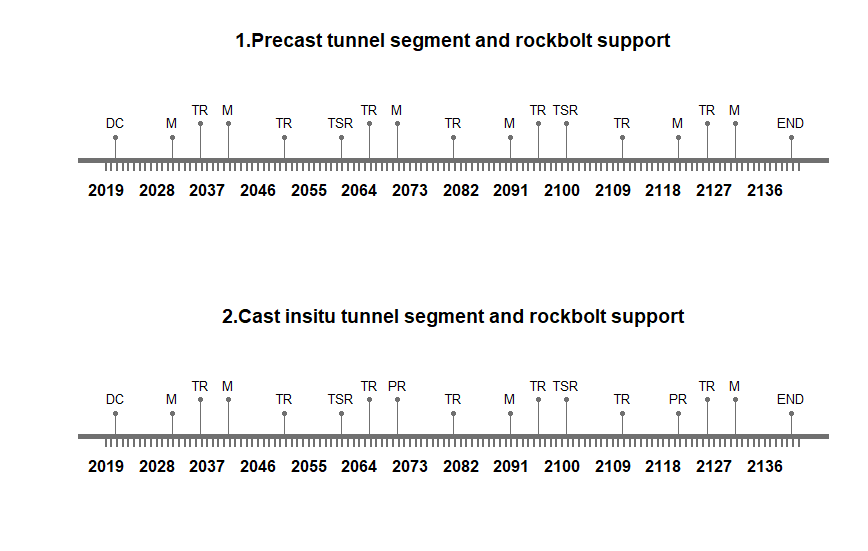

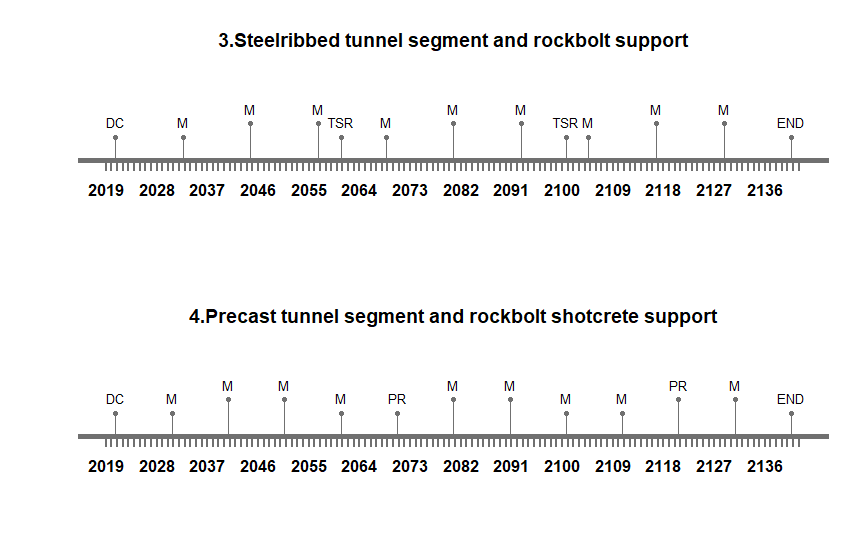

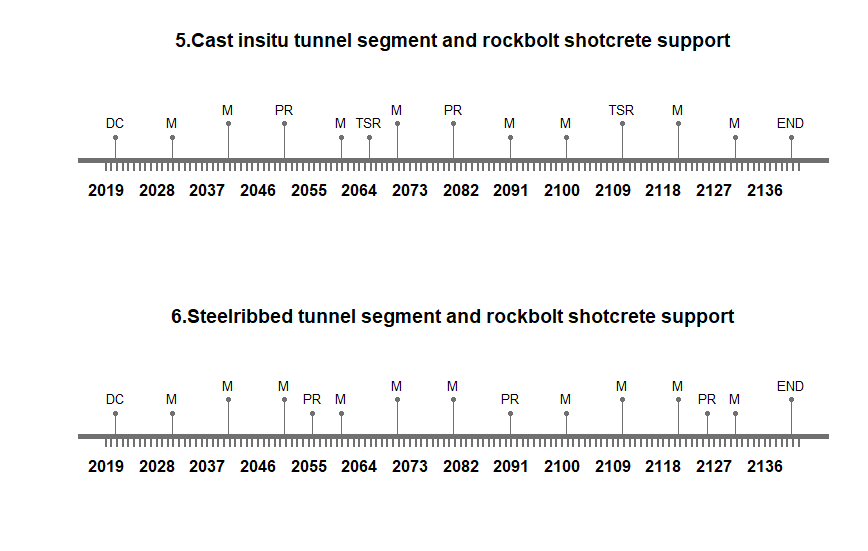

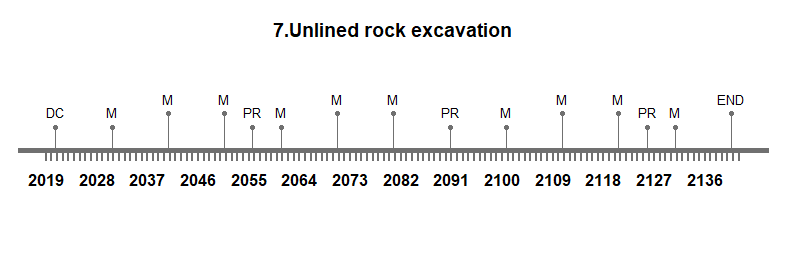

Within R , timelineS package is used to create time frame for each maintenance activities of Tunnel system. The overall design period/lifetime considered for tunnel is 120 years. Events is a vector of interventions including the frequency of each intervention. The vector for the first design option is defined as events. Op1 <- c(TR = 15, M = 10, TSR = 40, END = lifetime), where TR is tunnel refurbishment performed every 15 years, M – is the maintenance performed every 10years and TSR is tunnel segment replacement performed every 40 years. Similarly for all other options vectors are defined. Within different other vector option PR refers to permanent replacement. After defining vectors time line is drawn using the timeline S package, by which following figures are obtained. It represents the maintenance allowed for each of the 7 design options.

Life Cycle Inventory and Analysis

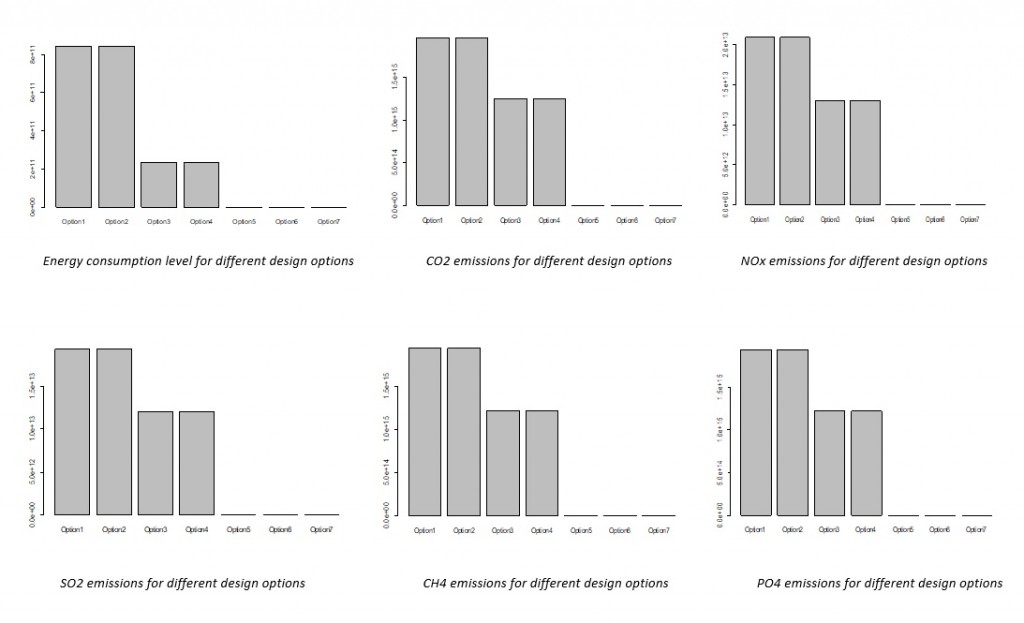

Based on a tunnel subsystems dimensions and different design options for the tunnel segment and support system the total amount of energy consumed as well as the total amount of emissions are computed as part of life cycle analysis. Using the R code, barplots are created to visualize different levels of energy consumption for the life cycle of tunnel design options.

Based on the input data given as amount the of energy and emissions for the materials of given quantity the bar plots are generated for six environmental indicators like energy, CO2, SO2, NO2, CH4 and PO4. All the graphs for emissions shows that Option 5,6 & 7 are best in regard with lesser emission where as Option 1 & 2 accounts for most of environmental degradation through the emissions. Option 3 & 4 has lesser influence on environmental indicators like CO2, SO2 etc. Mostly gases like CO2 & CH4 leads to global warming. While SO2 and NO2 are the reason for acidification of environment, where as PO4 accounts for eutrophication.

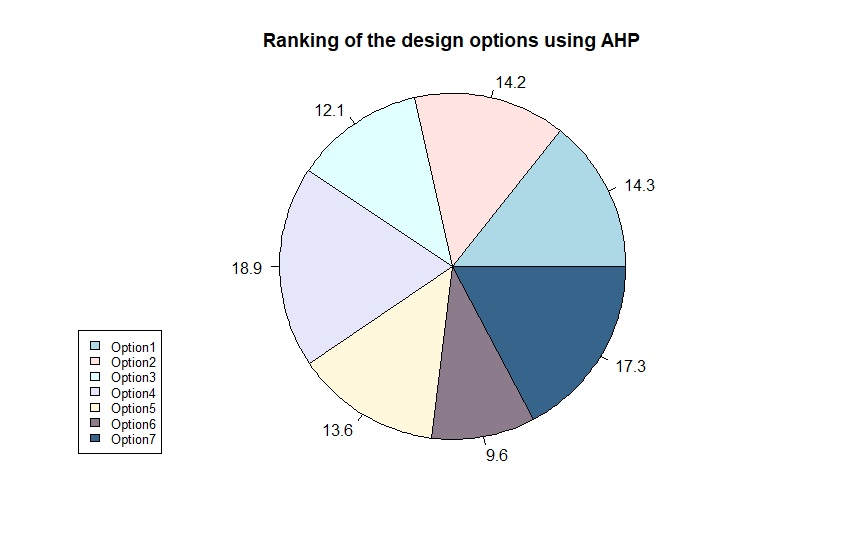

MCDM – Analytic hierarchy process (AHP)

Previously, looking at the barplots created for the levels of each indicator, best option was Option 5,6&7 which actually had the lowest level of all the indicators. Now we can see, that a more detailed analysis of our preferences changed the ranking, which in this case as shown in the results of the AHP method is Option4 by having the highest score.

Conclusion

A tunnel is a civil engineering system, which uses various processed materials for construction purposes naturally tend to account for environmental load such as global warming, acidification and eutrophication. These are due to the uncontrollable emissions of gases during production of tunnel components. Inorder to delimit the environmental load caused by these materials, analysis of various designs are carried out to produce best option for the tunnel design. Through the current study option 5, 6 & 7 turns out to be best design options . Based on AHP analysis Option4 by having the highest score.