Component and Parameter Analysis

The components chosen for this paper would be the sleeper and rail from a railway system. This components are chosen because of the significance of the decision making in terms of the amount of availability of the system and the impact it has on the environment.

One sleeper with the rail length of the distance between the middle point of the sleeper is chosen as the unit of calculation. This parameter is chosen to provide a simple but also scalable to be measured to a real system.

With the dimension of the sleeper: 2.6m x 0.25m x 0.15m (LxWxH)

And the dimension of the rail: 0.72cm(Head), 0.16cm(Web), 14.35cm(Foot) and 170cm(Height)

Design Options

6 Design options are chosen for this paper to be analysed. The options are a combination of multiple material of sleeper and rail. The materials chosen for sleeper are: Wood, Steel, Cast Iron and Concrete. Carbon Steel and Alloy Steel are chosen as the materials for the rail.

| DESIGN OPTION | sLEEPER MATERIAL | RAIL MATERIAL | Type of Maintenance |

| Option 1 | Wood | Carbon Steel | Manual or mechanized |

| Option 2 | Steel | Carbon Steel | Manual or mechanized |

| Option 3 | Steel | Alloy Steel | Manual or mechanized |

| Option 4 | Cast Iron | Carbon Steel | Manual |

| Option 5 | Concrete | Carbon Steel | Mechanized only |

| Option 6 | Concrete | Alloy Steel | Mechanized only |

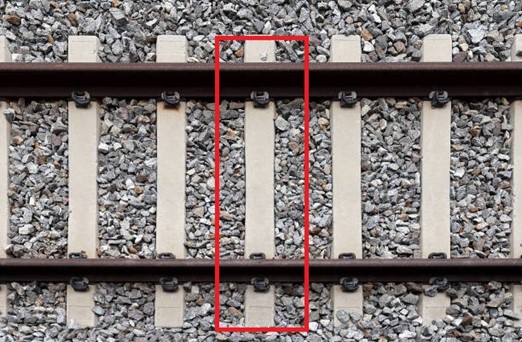

A couple of figures will be listed as an example to point out the differences between the options. Given the inability to differentiate carbon steel and alloy steel, it is decided, that only the pictures of different sleeper will be shown in the paper. The picture of concrete sleeper is already displayed on the first point.

The scope of this paper is about the life cycle between two components of the railway that is very strongly affected by the usage of the system. A summary of the optimization of life cycle, energy consumption and pollution generated from producing the materials is intended in this paper. Analysing and finding the best combination between different materials of different components is the goal of this paper. A system doesn’t only need to have its life cycle optimized, but its components, which is less energy consuming and climate friendly, to be chosen.

The life cycle time span of the rail and different materials of sleepers can be seen in figure 5. The red line inside the time span is the inspection intervention that is executed after a specific time. Since the rail is inspected every 30 days, the inspection line is drawn as a continuous line given that each year it would have 12 inspections. Whereas the wood sleeper inspection twice a year to make sure that the wood sleeper is in a good condition and doesn’t need to be exchanged. The concrete and steel sleeper on the other hand have to be inspected every 2 years to decide whether it needs to be exchanged or repaired. It is clear to see that the wood sleeper will need to be changed after 10 years. Thus 3 wood sleepers are actually needed for a full life cycle of the railway. Whereas the lifetime of the concrete and steel sleeper is similar to that of the rail which gives the benefit of not needing to be disassembled in case everything is working well and doesn’t need reparation.

This two components are chosen for the analysis because of the huge energy consumption and pollution that it created in comparison to other components of the railway.

Life Cycle Inventory of the Materials

Below is the life cycle inventory of each materials. The numbers in the table are taken from multiple sources. Several numbers are calculated as the average from multiple sources.

The quantity of the wood is three times more than the other sleeper due to its 10 year life span in comparison to 30 year life span of the other sleeper. The volume of the rail is calculated from the rail that is used in Germany.

| Material | Scope | Quantities | Energy | CO2 | NOX | SO2 |

| Wood | Sleeper | 0,2925 m3 | 606,75 MJ | 26,91 kg | 0,18 kg | 0,03 kg |

| Steel | Sleeper | 0,0975 m3 | 14695,2MJ | 1209,29 kg | 4,2 kg | 2,83 kg |

| Carbon Steel | Rail | 0,0057 m3 | 1136,52MJ | 105,15 kg | 0,01 kg | 0,0044 kg |

| Alloy Steel | Rail | 0,0057 m3 | 1395,36MJ | 118,56 kg | 0,11 kg | 0,2736 kg |

| Cast Iron | Sleeper | 0,0975 m3 | 13650MJ | 454,06 kg | 0,1 kg | 0,0075 kg |

| Concrete | Sleeper | 0,0975 m3 | 256,425MJ | 37,24 kg | 0,11 kg | 0,063 kg |

Table 1. Life Cycle Inventory List

Reference

World Steel Association, Life cycle inventory (LCI) study 2020 data release, May 2021, Belgium

Mitterpach; E. Hroncova; J. Ladomersky; K. Balco, Environmental evaluation of grey cast iron via life cycle assessment, 2017

Portland Cement Association, Life cycle inventory of Portland cement concrete, 2007

E. Puettmann, Life-cycle analysis of wood products: Cradle-to-gate LCI of residential wood building materials, 2005