The Aim of a Multi-objective Optimization is to give the stakeholders an assist by the decision-making process. The method works by generating a high number of solutions over an interval and evaluate the results based on the objectives and the key results or key performance indicators.

The Algorithm may take a high computational capacity. To overcome the problem, the models are usually reduced to the minimal needed complexity. The model of the integrated system has eight Parameters and nine outcomes. The algorithm will randomly generate, inside the given boundaries, a finite number of models and evaluate them based on the weighing of the criteria and choose the best models or solutions. Models, which have the best evaluation are called a Pareto Optimality and the whole group of best solutions is the Pareto frontier. Pareto optimality is defined as a state or an instant, which balances the results of the model in a way, that moving away on the Axis of any parameter will not result a bettering of the performance of a criterion without degrading another criterion.

Due to the complexity of the models, the maintenance interventions for the subsystems examined in the second assignment are used instead of the overall systems. The parameters of the model can be expanded here as required.

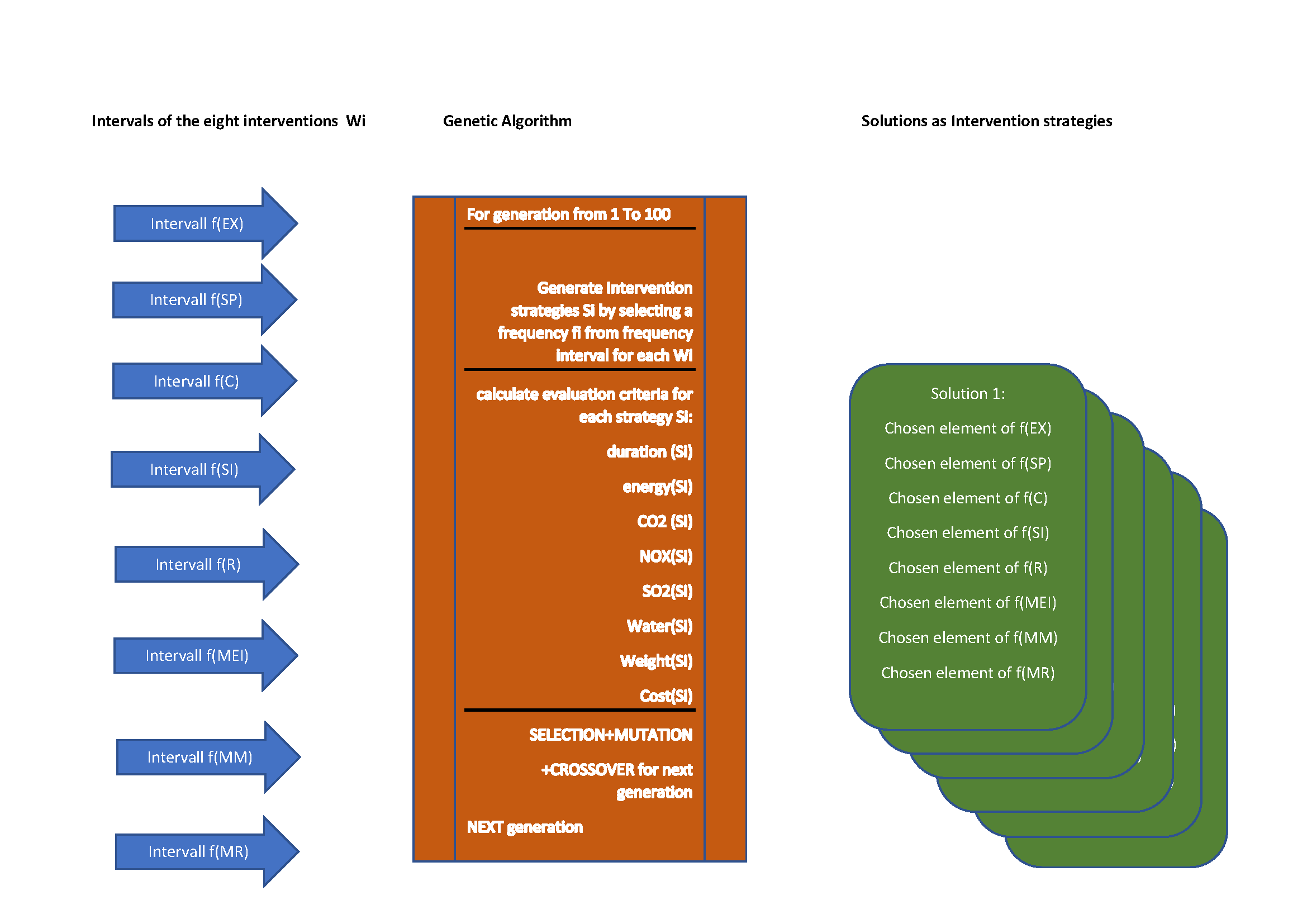

Genetic algorithm:

The input parameters are the maintenance interventions associated with the individual systems with their resulting environmental costs, durations and medium frequencies.

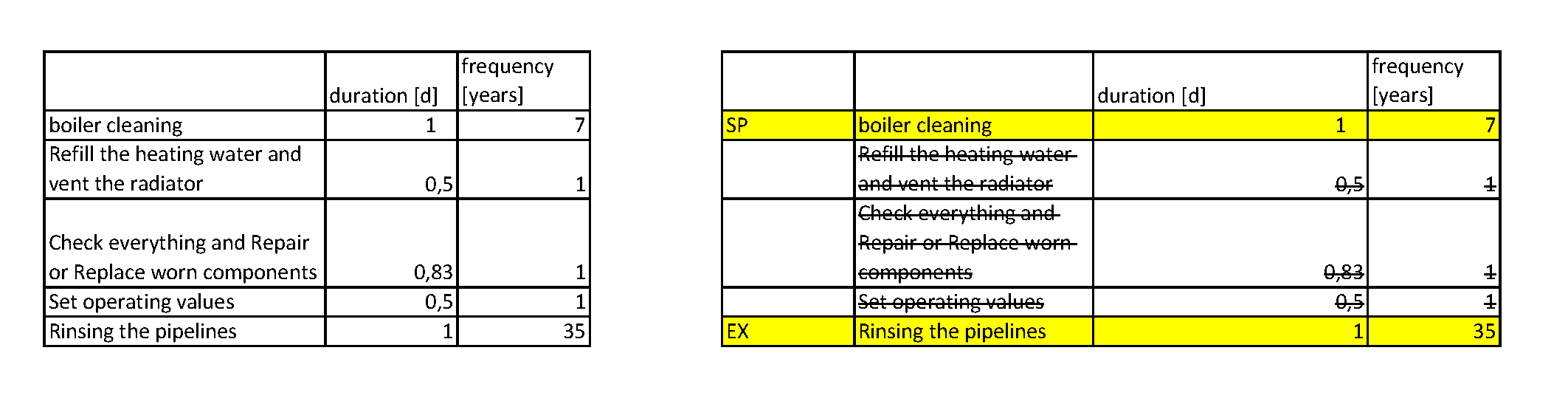

In the heating system there are 5 maintenance interventions, in the wind turbine tower there are 3 and in the ceiling of the parking garage there are also 3 interventions. With regard to the model complexity presented above, each of these variables must be weighed up to determine whether it makes sense to include these interventions.

With the heating system, it quickly becomes clear that the three interventions that are carried out annually, but lasting less than one working day will not have a major impact on the results.

Therefore, they are omitted from the calculations. The interventions of the heating system used are marked in yellow.

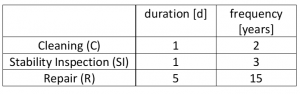

For the wind turbine there are 3 different maintenance actions listed in the table below:

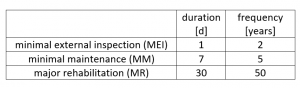

For the car park there are also 3 different maintenance actions listed in the table below:

Around this an interval is generated in which these frequencies are varied. The genetic algorithm varies and combines different individuals in 100 generations. An individual is a complete maintenance plan that sets the frequency for all of these 8 required interventions.

For the sake of simplicity, the assumption is made that the relationship between frequency extension and environmental costs is linear. This is an assumption that is plausible in its direction, but certainly does not correspond to reality in its quantitative size. Nevertheless, the model shows the logical connection:

If you wait longer between interventions, the costs increase.

If intervention is brought forward, costs will decrease.

If W1 is a maintenance intervention and fm (W1) the suggested frequency, then C1 is defined as:

C1! = C (W1, fm (W1))

If the frequency is now extended / shortened to f, the changed costs C for this frequency are proportional:

C = C1 * f / fm (W1)

This applies to all maintenance interventions Wi.

In the following picture the algorithmic process of the computing is shown:

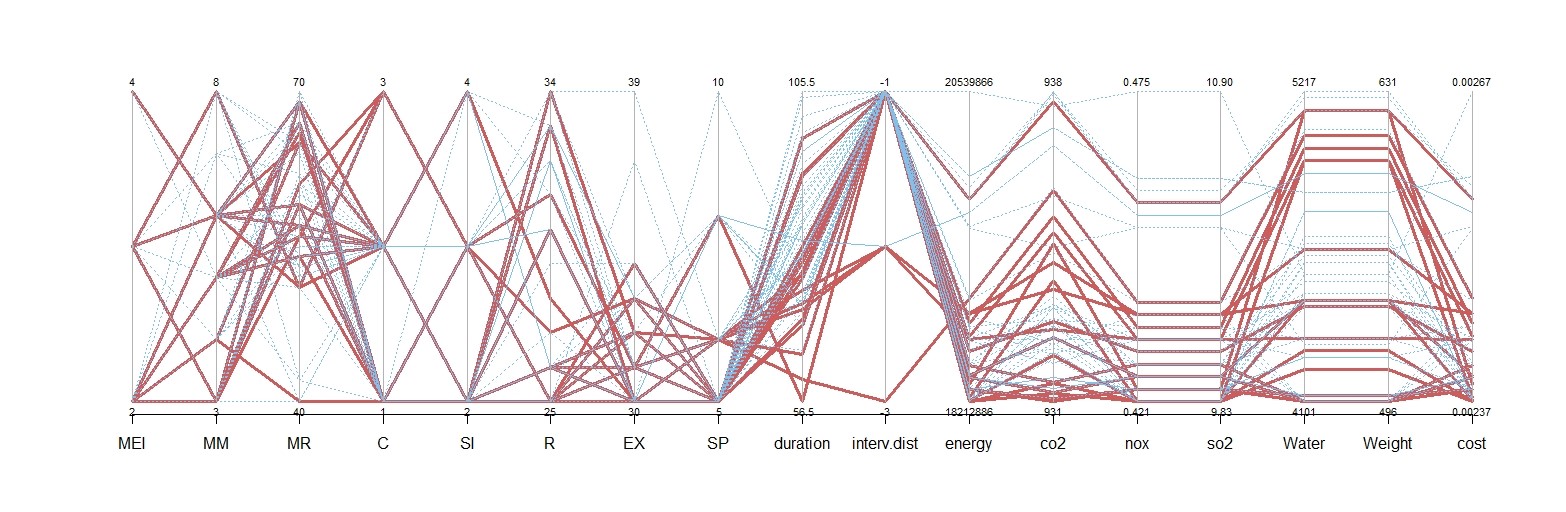

The three evaluation criteria that we follow in this integration context are Costs, Total intervention Time and the distance between the interventions. The distance between the interventions is to be maximized and the other two criteria are to be minimised.

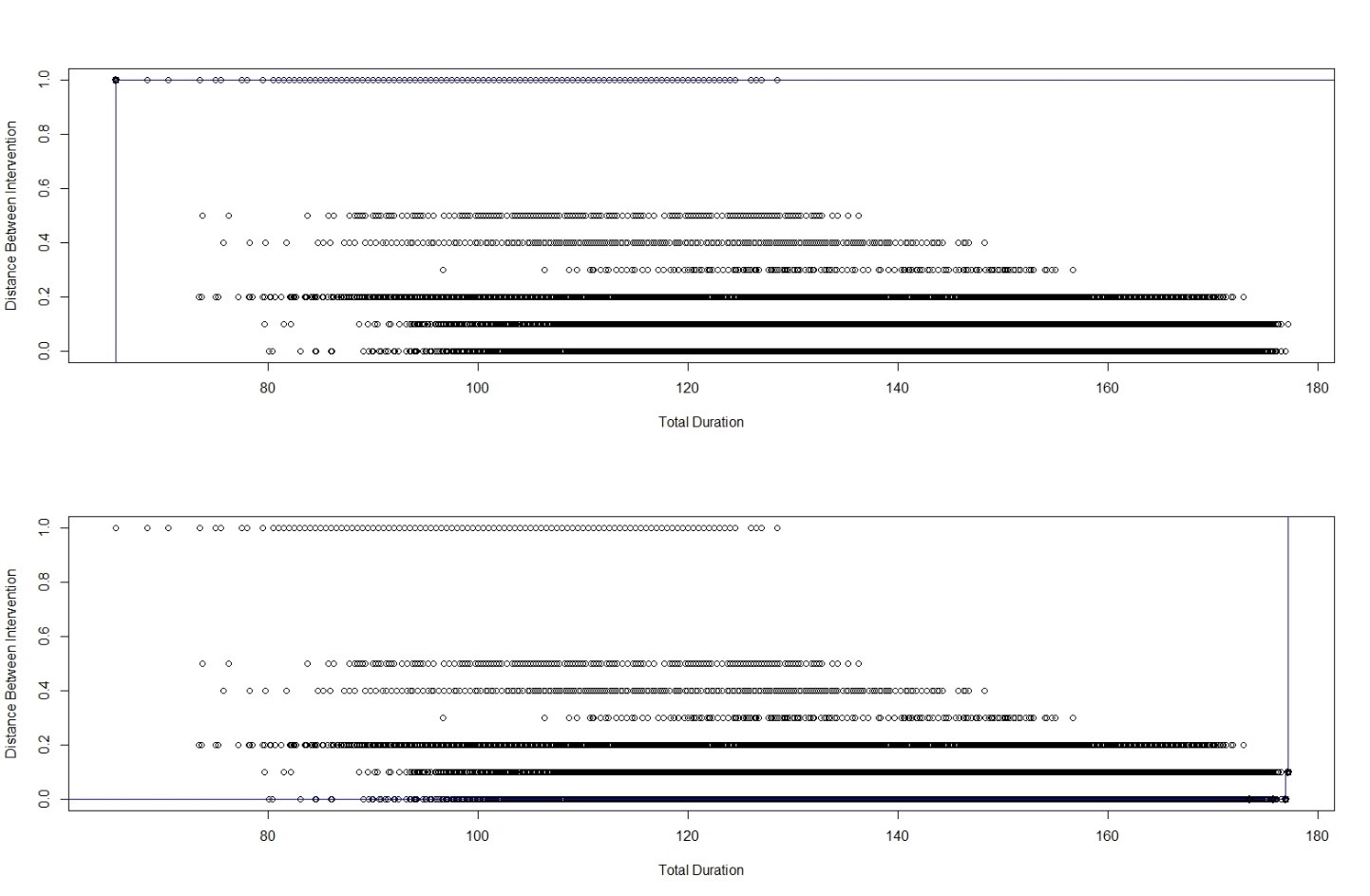

In the following diagrams, the duration and the distance between the interventions are visualised. The blue line represents the pareto frontier of the best, or in the second graphic the worst, variants.

The result of the calculations is now a finite number of solutions. A weighting of the evaluation criteria by a decision maker would thus follow this calculation.

A suitable variant for the stakeholder can be selected from this using a Multi Criteria Decision Method (f.E. AHP, TOPSIS).