1. Introduction:

One of the most important components for offshore structures is offshore piles. Offshore piles have been commonly used as a foundation element of offshore structures, dealing with the water and soil give the offshore piles the importance of studying the life cycle timeline, inventory and analysis.

2. Goal & Scope:

The purpose of this study is to provide a comprehensive, scientifically based, impartial and accurate understanding of the environmental pressures associated with the production, use and disposal of offshore piles using the LCA methodology.

And the scope for this study is:

- A life cycle inventory of three marine pile types: treated wood, concrete and steel.

- Calculation and comparison of life cycle impact assessment indicators.

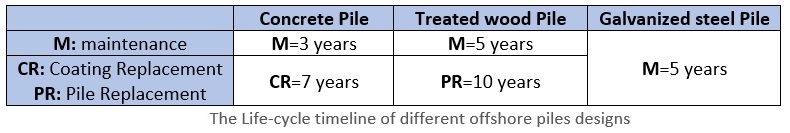

Fig.1: System boundary and process flows for marine piles.

Cradle-to-gate processes for treated wood are shown in green and non-wood products are shown in blue.

Gate-to-grave processes are shown in black as combined.

3. Design options and Life-Cycle timeline:

- Concrete offshore pile: Concrete piles are common structural foundation elements used to support offshore structures such as bridges, oil-rigs, and floating airports.

- Galvanized steel offshore Pile: Steel piles buried in relatively impervious ground at least two feet below the surface of the earth will not normally corrode due to the lack of oxygen in the atmosphere. Steel piles having different types (Steel H-Pile, Steel Rail Pile, Steel Box Pile, Disk Pile, Screw Pile).

- Treated wood offshore piles: Timber piles are available in a variety of sizes and strengths. A regular timber pile is a tree with straight trunks and cut branches. The butt diameter ranges from 12″ to 20″ and tip diameters from 5″ to 10″.

Fig.2: Piles design options

Fig.2: Piles design options

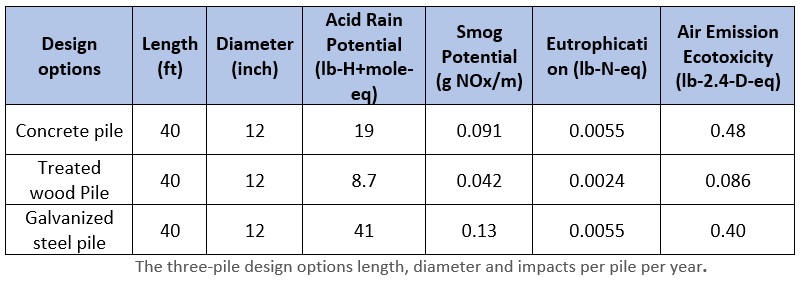

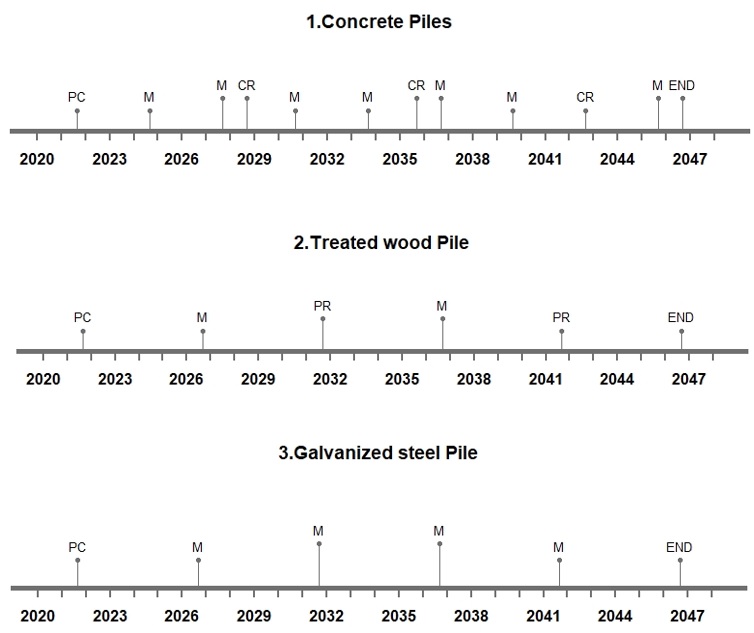

By organizing the life-cycle timeline in the table below, and simulating the details in R, by using timelineS package to create time frame for each maintenance activities. Considering that the overall design lifetime is 25 years for the offshore systems, and the start date of Pile Construction (PC) is assumed to be 01/01/2022, the following results will be obtained.

Fig.3: The Life-Cycle Timeline for the different pile’s options

Fig.3: The Life-Cycle Timeline for the different pile’s options

4. Life Cycle Inventory and Analysis:

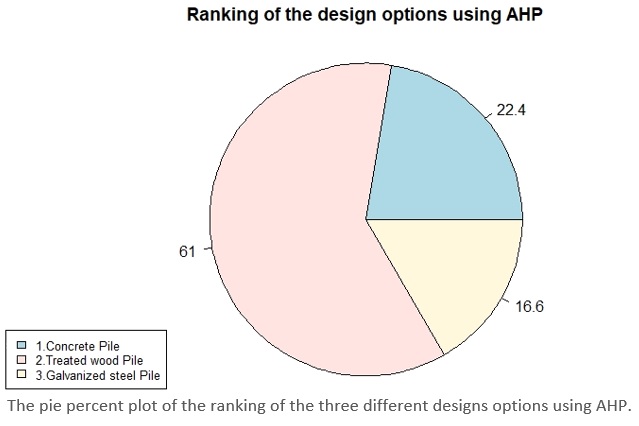

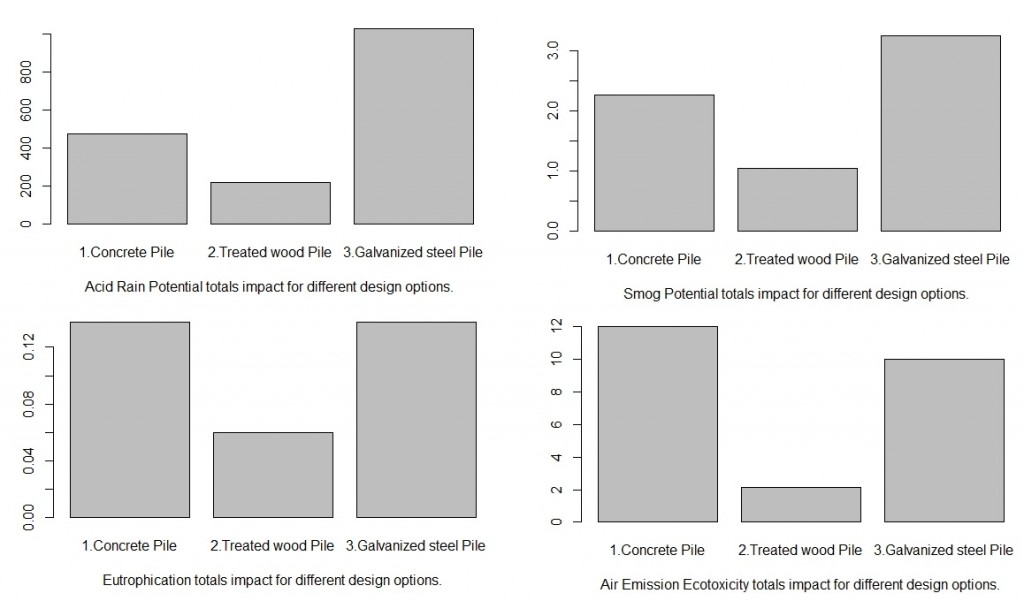

As mentioned in the goal and scope, the life-cycle inventory for the three options of offshore piles is their impacts on the environment. The following table shows the length and diameter of the three pile design options which used in the life-cycle inventory, and the information which collected about (Acid Rain Potential, Smog Potential, Eutrophication, Air Emission Ecotoxicity) for each pile.

These results were calculated based on the pile sections for one year and by simulating this information in R with the lifetime 25 years the life-cycle inventory for the three options for each impact will be given below.

Fig.4: The indicators total impacts of the three piles design

Fig.4: The indicators total impacts of the three piles design

The results shown that the treated wood pile have the lowest impact during the life-cycle. On the other hand, galvanized steel pile have high values especially in acid rain potential and smog potential, while concrete pile has the highest value regarding to air emission ecotoxicity.

5. Multi-Criteria Decision Analysis – Analytic hierarchy process (AHP):

Regarding the different impact, the decision maker should study the analysis of multi-criteria decision to be able to choose the best design option. First the score matrix should be defined for each performance criteria, noting that the matrix should be defined based on the level of preference of these criteria amongst the design options.

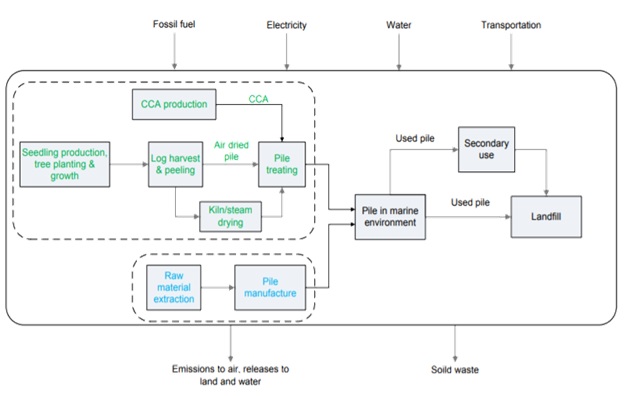

By simulating these score matrix in R, the AHP results will obtained below:

Regarding to the Life-Cycle Inventory, the treated wood pile have the lowest totals impacts of different indicators. Moreover, noticing that from the pie percent in the AHP ranking the treated wood pile has the highest percent (61%) which mean it is the best option comparing with the two other designs.

Here the decision maker could have a full overview to decide what is the best option based on the preference values which should be put in the score matrix and the thoughts of the decision maker about the preference of each indicator compared with other indicators.

References:

1. Life cycle assessment of CCA-treated wood marine piles in the U.S. with comparisons to concrete, galvanized steel, and plastic marine piles. Christopher, A. Bolin and Stephen, T. Smith. January 2012, Journal of Marine Environmental Engineering.

2. Grand, Bernard A. TYPES OF PILES: THEIR CHARACTERISTICS AND GENERAL USE. Pile foundations. 1970, 333, pp. 3-15.

3. Steel sheet piles used in construction projects. ENGINEERING NEWS. [Online] December 1, 2020. https://www.engineeringnews.co.za/article/steel-sheet-piles-used-in-construction-projects-2020-12-01.

4. Rollins, Martin. Timber Piling Design. WoodWorks. [Online] 2012. https://www.woodworks.org/wp-content/uploads/Rollins-Timber-Piling.pdf.

Other systems:

Integrated Maintenance Planning