Introduction-

The subsystem for this LCA study is a combination of layers of a pavement. Basically, we have chosen to disregard the sub-base and study the top layers of the pavement. The selected pavement layer for your LCA study comprises a modified asphalt surface friction course (MASF) for the top surface, a combination of binder and asphalt concrete (BAD) serving as a base course, an ashphalt bitumen (AB) providing foundational support, and a layer of concrete with specific functions based on its placement within the pavement structure. This combination aims to achieve a resilient, durable, and structurally sound pavement system.

In an LCA study, we would assess the environmental impacts associated with the production, use, and end-of-life phases of these pavement components, considering factors such as energy consumption, emissions, and resource depletion. The significance of Life Cycle Assessment (LCA) in evaluating pavements cannot be overstated. Remarkably, there has been a sparse publication frequency of one study per year dedicated to performing LCA on pavements, spanning the years 1996 to 2010, as exemplified by the work of Alex Loijos. Loijos’s research contributes to the broader understanding of the environmental impact of pavements by employing the LCA methodology.

Goal and Scope-

The main objective of this assessment is to conduct a comprehensive carbon footprint analysis, aiming to quantify the greenhouse gas emissions associated with a specific system or activity.

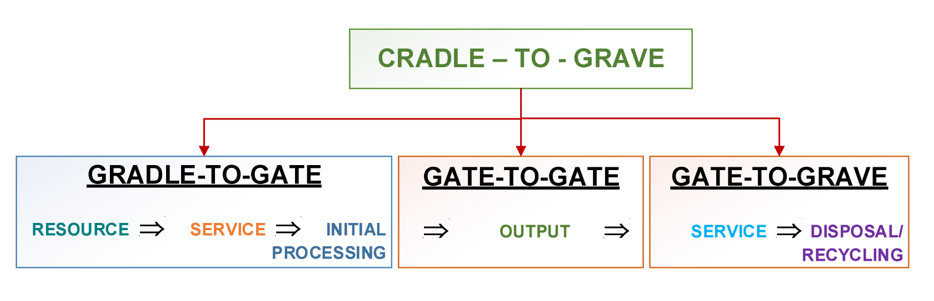

Life cycle assessment is a method within the field of industrial ecology that can be generally applied to industrial systems. LCA comprehensively quantifies, and evaluates the material and energy flows of such a system. These materials and flows are inventoried throughout the “life cycle” of the product and/or service that comprises the system, including upstream (raw material extraction, processing, transportation, and construction), use (reuse and recycling), and downstream (deconstruction and disposal) flows. (Alex Loijos). In a recent literature review of pavement LCAs, 12 studies were evaluated for their inclusion of five different primary phases in the pavement life cycle: materials, construction, use, maintenance and rehabilitation, and end-of-life (Santero 2010). Of these 12 studies, not a single study included all five phases, and half of them excluded more than one phase. (Alex Loijos). So we need a more holistic study. The disposal of construction material as landfill, or their recycling uses enormous amoung of energy. For a pavement, it crucial to conduct a Cradle to Grave analysis, as the Initial Processing of the constructin material is only a fraction of the total emissions generated. However, we are working with just the scope of Cradle to Gate, as explained further below.

Boundary-

We are limiting ourselves to the emission generated during manufacturing. Just as we saw in the Bridge tutorial. A more comprehensive LCA can be performed with a cradle to grave approach, but we have the data available for Cradle to Gate so we proceed with this.

Alternatives-

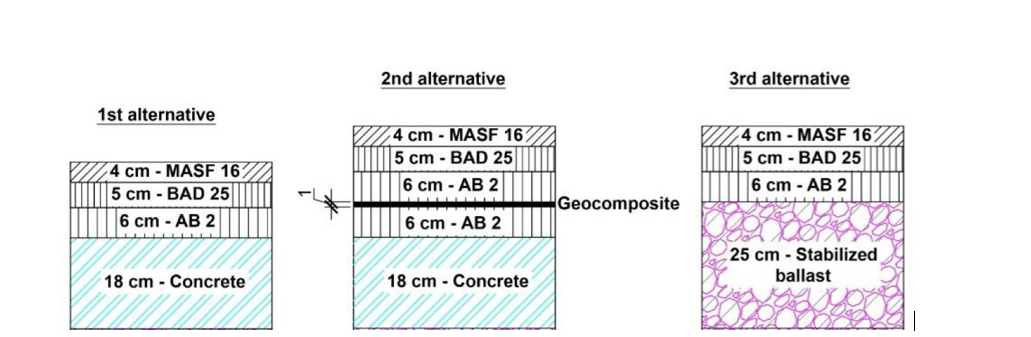

The three alternatives were analysed for a Case Study in Romania which involved an actual rehabilitation of an existing pavement. The case study uses LCA framework and theory have been described in the ISO 14040 and ISO 14044 series standards, which calculate the life cycle in a quantitative framework. The three design options are visualized as-

| MASF | Fibre stabilized ashphalt mixture |

| BAD | Lightweight ashpahlt concrete |

| AB | Ashphalt Bitumen mix |

| Concrete | M30 grade |

First alternative: Reinforcement, according to the third variant. The laying of three layers of asphalt mixtures.

Second alternative: Reinforcement with geocomposite, according to the third variant. The laying of the asphalt mix layers over a geocomposite.

Third alternative: Complete restoration of the pavement structure, according to the second variant. (Life Cycle Assessment of Concrete Pavement Rehabilitation: A Romanian Case Study). The material quantities are calculated in Romanian Case Study, along with the description of the materials used as mentioned above.

Life cycle Inventory-

The inventory presented in this analysis deliberately excludes transportation, focusing exclusively on the cradle-to-gate scenario. By adopting this approach, the study delves into the environmental impacts from the inception of the materials’ life cycle to the point they arrive at the gate, encompassing the stages of extraction, processing, and manufacturing. For concrete, the values utilized in the inventory are sourced from the tutorial, aggregating individual elements such as cement, which notably accounts for 85% of energy consumption and emissions (Marceau, 2007), along with coarse aggregate and fine aggregate. The selection of these components aligns with a comprehensive understanding of concrete’s environmental footprint.

Interventions-

The data for interventions in this analysis is sourced from Chapter 6: Routine Maintenance Practices in the publication “GUIDELINES FOR ROUTINE MAINTENANCE OF CONCRETE PAVEMENT.” This data serves as a crucial component in understanding and modeling the life cycle of the pavement, particularly in the context of routine maintenance practices.

It’s notable that, despite the chosen design period of 40 years, the pavement is anticipated to surpass this timeframe in terms of its expected lifespan. Within this extended lifespan, the typical maintenance strategy involves rehabilitation twice—once at the 20-year mark and again at the 30-year mark. Notably, both the first pavement design option and the one incorporating a geocomposite layer share identical preservation, structural, and functional CPR (Condition Performance Rating). However, a nuanced engineering rationale guides the interventions for the second design option. In this case, only one rehabilitation and restoration (R&R) intervention is prescribed.

Design options-

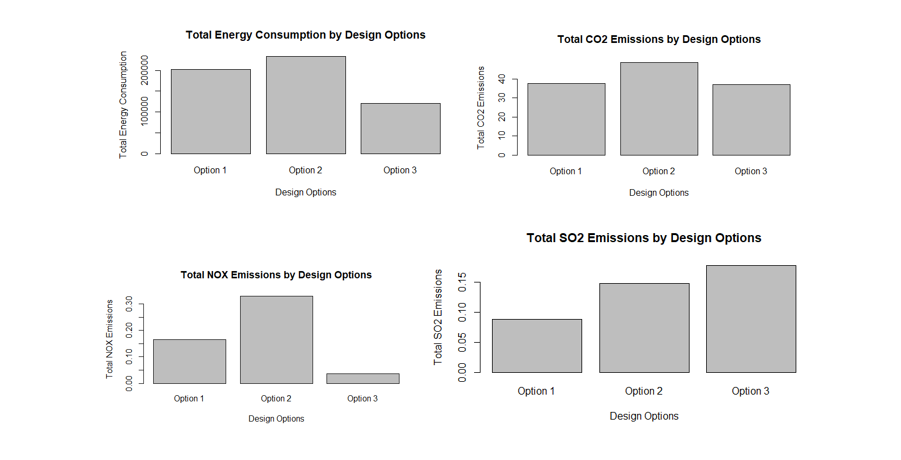

The AHP process is particularly noteworthy for its ability to tailor the matrix preferences to our specific requirements, resulting in the identification of an optimal design option that may not be readily apparent from graphical representations. AHP serves as the key to unlocking the intricate and captivating technique of Multiple Criteria Decision Making (MCDM).

Pairwise comparision and AHP-

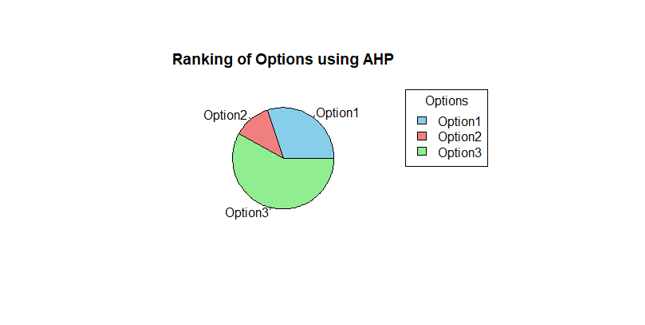

Using the barplots we try to ascertain which design options are generating the most emissions and are the most expensive. Which is Option 2, because it is using two layers of AB2. Setting up the AHP matrices, we can use this information to classify our options into a hierarchy depending on our preferences. We can choose the best possible Option, which seems to be Option 3, but we do not know for certain. The pairwise comparision values have been chosen arbitrarily by me. To make the AHP process a bit more complex, I have selected the SO2 emissions of Option 3 to be higher than the first two option. The value may be incorrect, but I want to study the outcome of ranking process by adjusting the matrix preferences.

From the pie chart we can see that AHP still prefers Option 3, which was higher in SO2 emissions but lower in the remaining three criteria. We can try to close the gap between Option 1 and Option 3 by selecting Energy Consumption and NOX emissions as a higher preference to calculate ranking, but Option 3 is still more competetive.

In conclusion, it is imperative to acknowledge that while emissions from the pavement are a focal point in most analyses, it is equally crucial to recognize that pavements contribute to emissions by promoting the use of private vehicles. The construction of extensive highways, for instance, inadvertently promotes the reliance on private vehicles. In the absence of viable alternatives, citizens are compelled to acquire more cars, each carrying an embedded carbon footprint. Consequently, such policies inadvertently act as catalysts, fostering an upsurge in the purchase and utilization of vehicles, thereby exacerbating carbon emissions.

Home Page | Maintenance Strategies | Life Cycle Analysis | Multi Objective Optimization