Introduction

Our Energy Efficient Dam Maintenance and Storage Facility is comprised of several different models, each altered slightly to fit within our global context. The dam in the Dynamo model will provide structural reliability and safety to the rest of the system. The warehouse will serve as storage space and a maintenance facility for the dam, while an office building was designed inside the warehouse. The encompassing theme is energy efficiency, with solar panels based on the main building warehouse roof powering the inside operations.

Design Integration

Our first task was to combine the warehouse and dam models. The size of the dam was dependent on the size of the warehouse. Since, the size of the warehouse and office will affect the amount of energy consumed by the functions of the building. However, the covered area of the warehouse will be based on the traffic passing the dam per time. As the surface area of the dam increases, the design needs to be adjusted accordingly. The slope parameter of the dam height decreases with the increase in height to avoid overturning or sliding due to active loading or uplift.

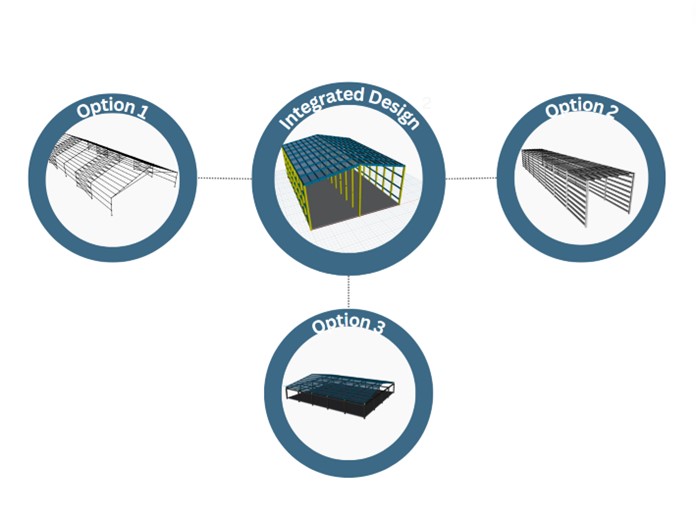

In our hypothetical environment, the warehouse was not only proposed as a place to deposit the cargo relating to the harbor activity, but it was also assessed as a critical support facility for the maintenance activity of the dam. We had three warehouse designs from three different group members, but decided to combine these into one integrated design composed of each models components to better address all the goals of our project.

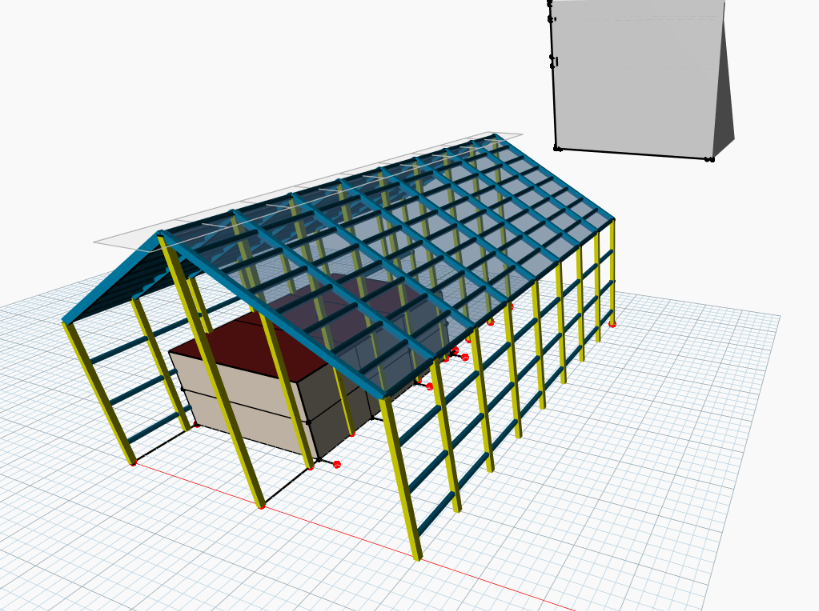

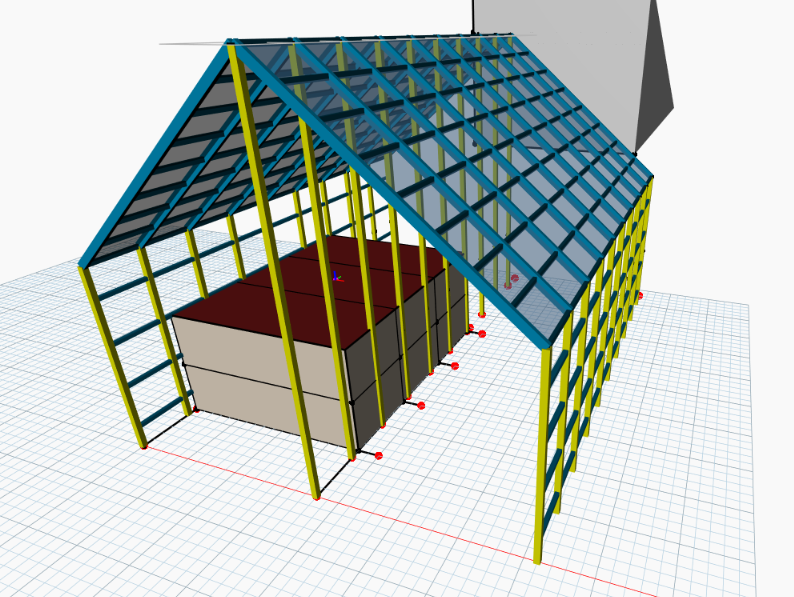

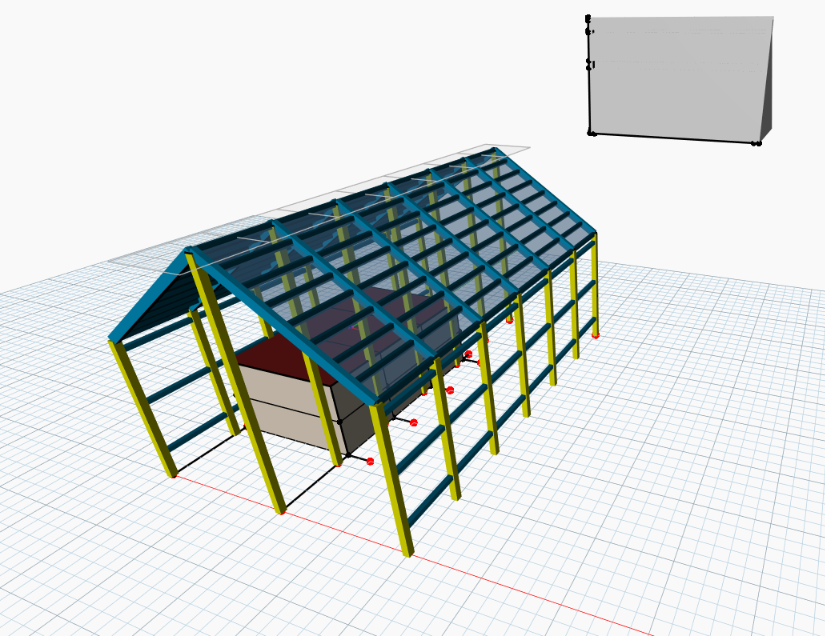

One warehouse included optimized storage space calculations, another focused primarily on structural reliability. Ultimately, we chose a fully steel warehouse that combined these design choices with the final model – one that had considered solar panels. This added the benefit of providing larger clear spans and height for storage. We opted for the ease of integrating energy-efficient solutions as being most important to contributing to the project’s sustainability goals.

We then decided to place the office building inside the warehouse. The office building will provide workspace for employees and further storage. The RCC structure of the office was enveloped from all sides with wall surface. The office building is aligned with the steel columns of the warehouse, so that for any vibration experience both the structures oscillate in synchronization thus maintaining structural integrity.

Lastly, we integrated the solar calculations. The original model was based on a residential building, but as energy demands may be similar for an office building, we decided that the calculations would still apply. In this case, however, we had more roof space to work with seeing as the solar panels would be situated on top of the warehouse roof. Our generation potential was therefore much greater than the office energy requirements, even when only one side of the warehouse roof was utilized for solar power.

Parameters

For our encompassing global parameters, we selected the dimensions of the warehouse and the angle of the warehouse roof. All other inputs were made dependent on these global parameters. The parameters are summarized in the table below:

| Main Parameters | Dependent Parameters |

| Warehouse Height | Dam Height, Dam Slope, Office Height, Office Floors |

| Warehouse Roof Angle | Solar Panels |

| Warehouse Length | Office Length |

| Warehouse Width | Office Width |

Performance Criteria

As established earlier, our focus is to maintain the structural reliability of the project while keeping it energy efficient. The performance criteria calculated are listed below.

| High Performance Criteria – Structural | High Performance Criteria – Energy Efficiency |

| Storage Capacity | Number of Solar Panels |

| Dam Strength | Potential Generation Per Day |

| Axial Rigidity of RCC Column | |

| Flexural Rigidity of RCC Beam |

Alternatives

For parametric modeling, three design option were considered.

- Design Option 1

| Design Option 1 | Value |

| Warehouse Height | 12 |

| Warehouse Roof Angle | 30 |

| Warehouse Length | 40 |

| Warehouse Width | 30 |

Performance Criteria for this design option is presented below.

| High Performance Criteria – Structural | Value | High Performance Criteria – Energy Efficiency | Value |

| Storage Capacity | 900 | Number of Solar Panels | 208 |

| Dam Strength | 588000 | Potential Generation Per Day | 1248.5 |

| Axial Rigidity of RCC Column | 3.48 x 10^6 | ||

| Flexural Rigidity of RCC Beam | 13.6 x 10^3 |

- Design Option 2

| Design Option 2 | Value |

| Warehouse Height | 15 |

| Warehouse Roof Angle | 40 |

| Warehouse Length | 48 |

| Warehouse Width | 36 |

The size of the warehouse was increased subsequently the sizes for office building and dam also increased.

| High Performance Criteria – Structural | Value | High Performance Criteria – Energy Efficiency | Value |

| Storage Capacity | 1100 | Number of Solar Panels | 300 |

| Dam Strength | 705600 | Potential Generation Per Day | 1905.4 |

| Axial Rigidity of RCC Column | 2.79 x 10^6 | ||

| Flexural Rigidity of RCC Beam | 9.48 x 10^3 |

With the increase in height, width and length the storage capacity and number of solar panels increased. The axial rigidity and flexural rigidity decreased as the increase in span causes the structure to become more flexible. The dam strength increased as its slope caused an increase in the horizontal length.

- Design Option 3

| Design Option 3 | Value |

| Warehouse Height | 9 |

| Warehouse Roof Angle | 35 |

| Warehouse Length | 30 |

| Warehouse Width | 20 |

A design with decrease in the size is considered. Roof angle was adjusted to see a typical potential generation per day.

| High Performance Criteria – Structural | Value | High Performance Criteria – Energy Efficiency | Value |

| Storage Capacity | 450 | Number of Solar Panels | 104 |

| Dam Strength | 441000 | Potential Generation Per Day | 660 |

| Axial Rigidity of RCC Column | 4.64 x 10^6 | ||

| Flexural Rigidity of RCC Beam | 30.7 x 10^3 |

Decreasing the dimension gave the trend as expected. Number of solar panels and storage capacity decreased as these variables were dependent on the built area. The shorter spans resulted in a more rigid structural frame as evident by the axial rigidity and flexural rigidity values.

Challenges

We had some trouble integrating the three different warehouses – mostly in choosing how best to represent the three systems. We at first considered a warehouse complex, with each model as a separate building, but we ultimately decided that one model would be an excellent representation of our project goals although slightly increasing the challenge of integration.