Evaluation of Pipe Materials Using AHP and Life Cycle Analysis

The scope of this study is, the analysis and Life Cycle Costs (LCC) within the production, transportation, and installation processes of different pipe materials used in sewer networks. The analysis excludes raw material extraction, recycling, and reuse but evaluates costs, energy consumption, and CO₂ emissions. Additionally, maintenance activities over a 100-year service life are considered, including periodic inspections that contribute to total costs, energy use, and emissions.

The assumption is that 1% of the initial construction cost must be spent on maintenance in each inspection period. When considering the cumulative impacts of production and periodic maintenance, significant differences between the materials become evident.

Environmental and Cost-Based Assessment

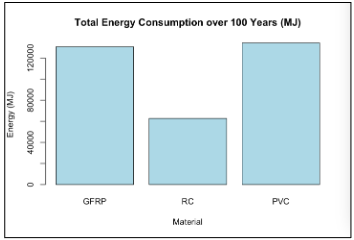

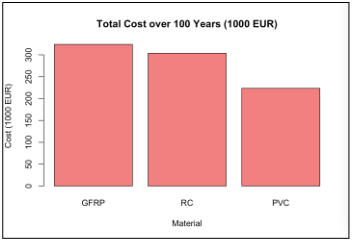

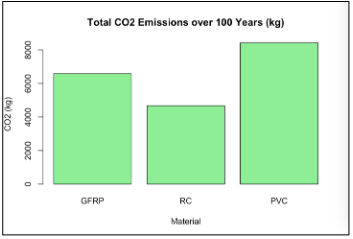

The results show that both PVC and GFRP require substantial amounts of energy and generate high CO₂ emissions. In contrast, RC exhibits significantly lower environmental impacts in these categories. Despite the common perception that concrete is environmentally taxing due to its high cement-related emissions, its superior long-term performance and lower maintenance needs help balance its overall environmental footprint. PVC, despite its relatively low production costs, demonstrates high emissions per unit of material, making it less favorable from a sustainability perspective. GFRP, while structurally efficient, also suffers from high embodied energy and cost concerns, diminishing its viability as the optimal choice.

Multi-Criteria Decision Making with AHP

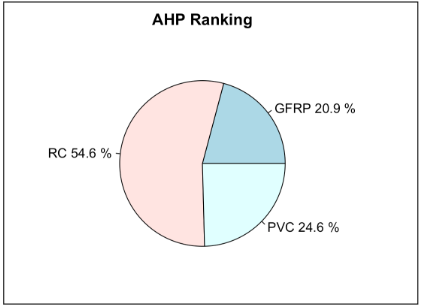

This study applied the Analytic Hierarchy Process (AHP) to systematically compare the three materials based on energy consumption, CO₂ emissions, and costs. A pairwise comparison matrix was established to determine the relative importance of each criterion. Given the increasing focus on CO₂ reduction in construction and the ongoing shift toward renewable energy sources, CO₂ emissions were given significant weight in the evaluation.

The AHP results confirm that RC emerges as the most suitable material, achieving the highest ranking with 54.6%. This outcome highlights its strong environmental performance while maintaining reasonable cost competitiveness. PVC ranks second with 24.6%, primarily due to its economic advantages despite its environmental shortcomings. GFRP ranks the lowest with 20.9%, as its high cost outweighs its moderate performance in the other categories.

Engineering Perspective on the Results

From an engineering perspective, the preference for RC over PVC and GFRP may seem counterintuitive at first, given that concrete production—especially cement manufacturing—is a major global contributor to CO₂ emissions. However, the decisive factor lies in the holistic assessment of long-term sustainability.

While alternative materials like PVC and GFRP require lower mass per unit, they exhibit significantly higher energy consumption and CO₂ emissions per unit of production. Their synthetic and composite nature results in an energy-intensive manufacturing process that offsets potential material savings. In contrast, RC’s longevity, structural reliability, and lower inspection frequency make it the superior choice when considering a full Life Cycle Analysis (LCA).

Conclusion

Based on the comprehensive analysis of costs, energy consumption, and emissions, RC is identified as the best-performing material for sewer networks. Despite its higher initial mass and production-related emissions, its lower maintenance requirements and balanced environmental performance over the long term make it the most sustainable and cost-effective option. The AHP results support this conclusion, reinforcing that RC should be prioritized for future sewer infrastructure projects where sustainability and cost efficiency are key considerations.