1. System selection and introduction:

The system used for the first assignment was a public playground for children consisting of

ground, swing, slide and see-saw. For the assignment in hand a combination of the ground and

the swing were selected, they were connected considering that the usage of the swing affects the

deterioration of the ground depending on the used material.

2. Parameter definition for the calculation of quantities:

The main parameter is the number of swing seats N. Which is used to calculate the dimensions of

the profiles used for the construction of the swing. The second parameter the area of the

playground A which is used to calculate the quantities for the selected ground material.

Two design options for construction of the swing are considered. The first is a steel construction

while the second is a wooden construction.

The Swing consists of mainly posts (vertical) a bar (horizontal). the number of posts is calculated

considering that every two swing seats need an additional post, therefore I used the equation:

NrPo = 1 + ceil(N/2). The necessary length of the bar is calculated with the equation: L = N*1,10

[m].

3. Design options:

Combining our possible design variations we get the following options to asses and compare:

Design Option Swing Material Ground Material

Option 1 Steel Rubber

Option 2 Steel Sand

Option 3 Steel Artificial grass

Option 4 Wood Rubber

Option 5 Wood Sand

Option 6 Wood Artificial grass

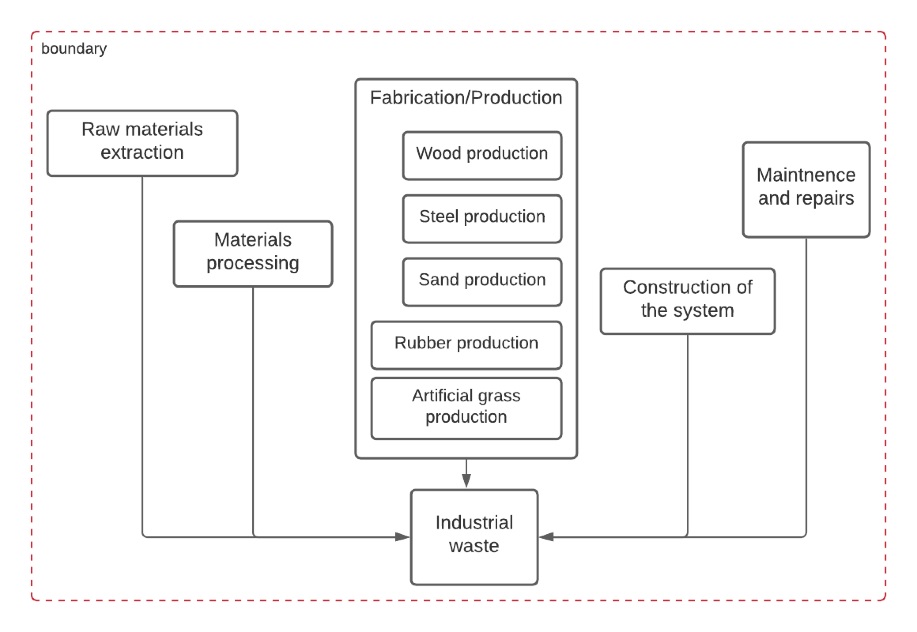

4. Goal and scope definition:

The main goal of the life cycle assessment is to evaluate the amount of produced industrial waste.

The scope and system boundary are represented in the following figure. The industrial waste

could be produced all along the way from the extraction of raw materials to maintenance actions.

That is why the system boundary must include more than just the construction and maintenance

of the system.

The necessary interventions that were considered in the assessment are listed below:

– RuRe: rubber replacement.

– P: Paint.

– RP: Repositioning.

– SaRe: Sand refill.

– GrRe: Grass replacement.

– JI: Joints inspection of the wooden construction.

The time lines with the necessary interventions were created for each design option. The following

figure is the timeline of design option 5.

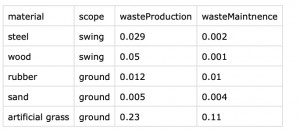

5. Life cycle inventory:

The amounts for each material is calculated using the mentioned equations. A life cycle inventory

has been established for each material and it includes the information about produced waste up

to the point of construction. In addition, the quantities needed for each intervention during the life

cycle of the subsystem. All amounts are provided in cubic meter. The values are imaginary and in

real life need to come from an authentic source of course. These values are stored in a csv file

that is also uploaded with the submission.

6. Life cycle assessment:

Based on the created timeline we get the amounts of intervention needed for each design option.

The total volume of industrial waste is calculated using the following equations using the following

equations:

Total waste = production waste + maintenance waste. Maintenance waste = maintenance waste *

quantity * number interventions.

Production waste = production waste * quantity.