INTRODUCTION

When engineers design a structural for a civil system, in addition to considering the stability of the structure, many other factors must be also considered, such as economic costs and various conditions during later operation. During the operation of the civil system chosen is the anti-corrosion layer of the segment in the tunnel, the system will experience structural deterioration or even system failure with the passage of events. At this time, manual intervention is required to maintain or repair to keep the entire system in normal operation. During this period, the maintenance and repair of the system will cause a non-negligible impact on the system, among which the impact on the external environment is the object to be studied in this operation. In addition to economic problems, the production chain involved in maintenance will also produce corresponding energy consumption and pollution, which is a very urgent issue that civil engineering needs to pay attention to in the current era.

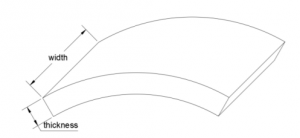

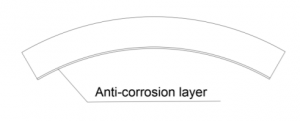

Here, The figure shows the simplify scheme and only the anti-corrosion layer of the inner layer of the segment is considered.

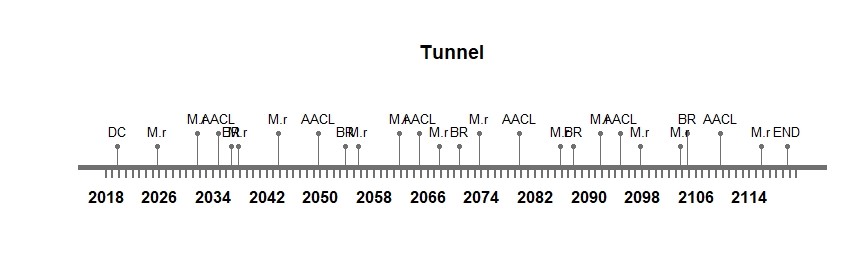

LIFE CYCLE TIMELINE

Here we assume that the life of the segment system of the tunnel is the same as that of the tunnel, both being 100 years.

This function will take as inputs the following:

• Lifetime – lifetime we assumed for out civil system – 100 years

• events – is a vector of interventions including the frequency of each intervention. As an example, this vector for the first design option is defined as events.Op1 = c(BR = 17, M.r = 6, AACL = 15, END = lifetime), where, AACL is Apply Anti-corrosion Layer, which means applying anti-corrosion coating every 15 years.

• start.Date represent the start date of the lifecycle- 2020-01-01

• option.Name – is the name of the design option:

1. Option 1 Tunnel

Its energy consumption and pollution emissions are superior to other solutions if we see the integrated model. In fact, there is no suspense, because in real life, concrete segments are basically used in shield tunnels, while steel segments and composite segments rarely appear in engineering examples. In fact, there is another type of segment: cast iron segment. However, cast iron segments are mostly used in tunnels with good geology long ago in Europe, and there is very little information that can be found. Compared with the commonly used concrete segment, cast iron segment, steel pipe segment and composite segment have many disadvantages, both in structure and later operation. Therefore, when talking about the structural design of shield tunnel segments, it generally refers to the structural design of concrete segments. Therefore, in practical engineering, concrete segment is the best choice.