Explanation of the System:

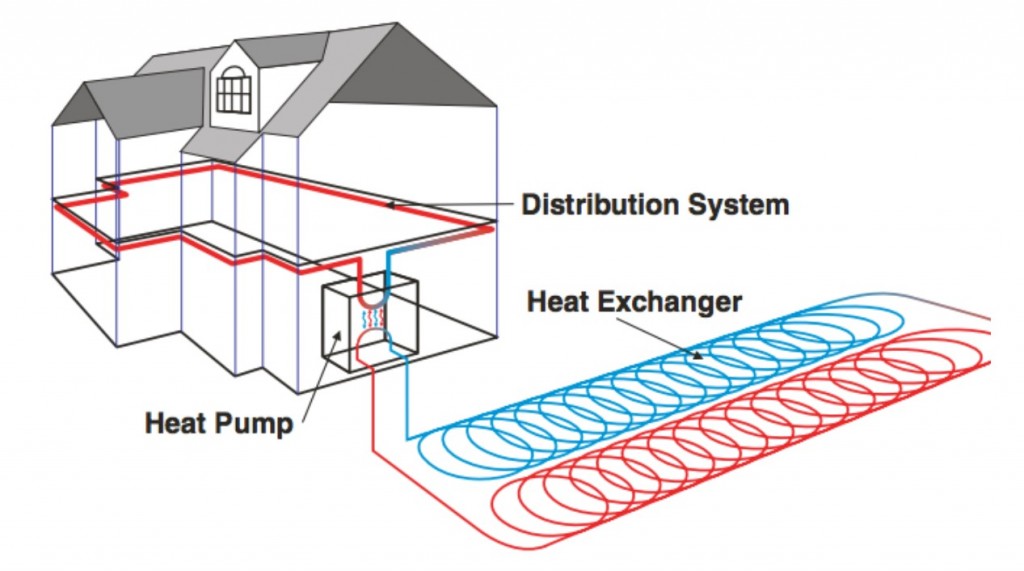

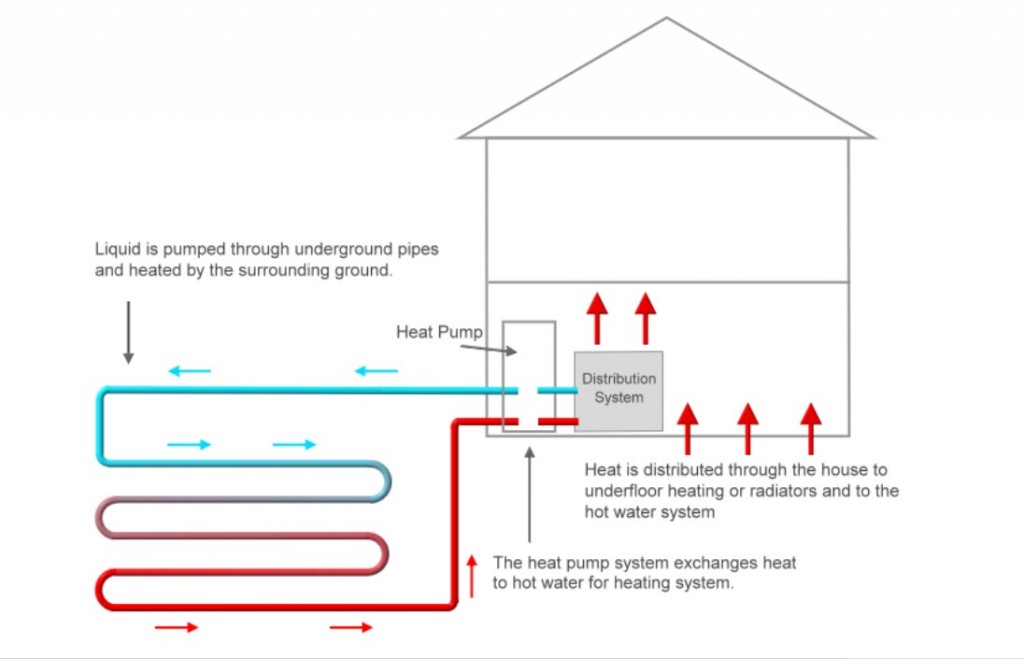

A ground source heat pump (GSHP) is a type of central heating system that utilizes the heat stored in the ground to provide heating. The GSHP system consists of an underground loop of pipes (Horizontally or a long vertical well instead), called a ground loop, that absorbs heat from the ground and transfers it to the heat pump. The heat pump then raises the temperature of the heat and uses it to heat the building. Due to high installation costs and less fuel costs, these systems are suitable for large consumers like hospitals. Furthermore, Since the temperature in the ground is constant in warm seasons, this system can be used to provide cold water for the facilities.

The use of renewable energy from the ground makes GSHP systems more energy efficient and environmentally friendly compared to traditional heating systems. Although this option is much more expensive in installation costs and digging the well than other options, it has big advantages like less CO2 and almost zero fuel cost. In calculations, I have made an assumption here, and it was that the amount of electricity to bring water from the well per unit is half of the using the electricity itself to boil water.

Dimension of the system:

In terms of materials, GSHP systems typically require copper pipes for the ground loop. A heat pump unit made of metal components pumps the hot water from an average of 100 meters depth to the surface of the earth. The material for the distribution system is steel.

- Well Diameter: 0.5 m

- Pipes: 40 t

- Well Length: 100 m

In the main, the estimated values for emissions are:

- 220 t of CO2

- 20 t of SO2

- 4 t of NOx

- 11415 MJ of Energy

Maintenance:

To determine the maintenance action, first, it is necessary to know the components of the system well:

- Ground Loop: This refers to a series of pipes buried underground that contain a fluid designed to gather heat from the ground.

- Heat Pump: This is a key component of the heating system that moves heat from the ground loop to the central heating system. It typically includes a compressor, evaporator, condenser, and expansion valve.

- Heat Exchanger: This component plays a crucial role in transferring heat from the heat pump to the central heating system.

- Control Panel: This component manages the temperature of the central heating system.

- Heading divide: That is the final destination of the system that heats rooms like radiators.

List of the three major maintenance actions:

- Regular Maintenance: regular inspection and cleaning. Also checking on the pump sector, oiling it, changing filters, and monitoring the Control panel. Overall, all small maintenance actions keep the system in a proper stage.

- Distribution system maintenance: This includes checking for any leaks, damage, or signs of wear and tear in the piping system in addition to the control of the radiators. The normal time interval is 6 years for this.

- Changing the main pump and more general repairs: due to the decreased lifetime of the heating system in comparison to the dam, we need to change that approximately every 12 years.

References:

- [1] https://metrohci.com/efficient-hvac-systems-des-moines/

- [2] https://greenbusinesswatch.co.uk/guides/ground-source-heat-pumps

- Holger Watter, 2015, Volker Quaschning Regenerative Energiesysteme, Foliant Publishing Hous, 41.

- Jean-Baptiste Videau and Anne Prieur-Vernat, 2021, Life Cycle Assessment of District Heating Systems in Europe: Case Study and Recommendations, ENGIE Lab CRIGEN, 11, 12.

- A. Bhatia, 2014, HVAC – Space Heating Systems, CreateSpace Independent Publishing Platform, 9, 13, 21, 23, 24.

- Valentina Turanjanin et al., 2015, Different heating systems for a single family house: Energy and economic analysis, University of Belgrade, 5, 11.