This railway bridge is located over the Kaiser Wilhelm channel, in the railway branch that connects St. Michaelisdonn and Wilster. It has a length of 240 meters, and its superstructure, the truss, is made of steel while the piers are made of precast concrete. The bridge is shown in the picture below:

Geometry

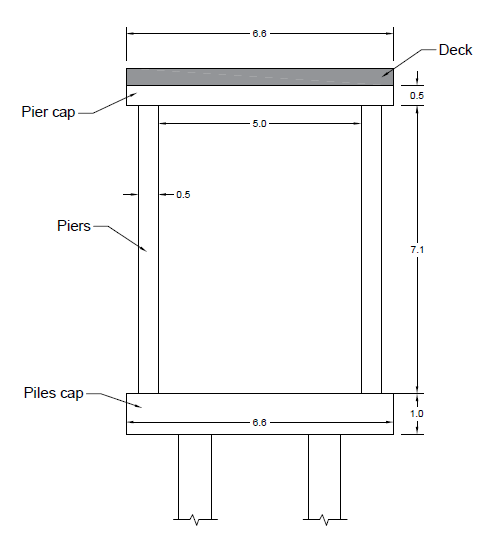

The subsystem of the piers and piles cap of the bridge was chosen as a subsystem to study their life cycle analysis. They consisted of a precast concrete frame; cylindrical piers and rectangular piers cap. The pile’s cap, rectangular-shape, is made of cast-in-place concrete. The piles are not included in the scope.

A rough sketch of the subsystem is presented below:

Material characteristics

Reinforced, cast-in-place concrete:

- Compression strength: 25 Mpa

- Raw materials components: cement, fly ash, coarse aggregates, fine aggregates, reinforcement

Precast concrete:

- Compression strength: 50 Mpa

- Raw materials components: cement, coarse aggregates, fine aggregates, reinforcement

Maintenance interventions

The expected lifetime of the bridge is 100 years. During that period, regular maintenance actions must be carried out over the subsystem. These actions are:

- Maintenance in piers and piles cap

Description: repair of cracks and carbonation and chloride process deterioration effect, in the concrete interface and in the appearance of the steel rebars corrosion.

Intervals: every 10 years

Duration: 10 days - Repairs in piles cap due to scour

Description: repair or eventually partial replacement of piles cap due to the soil erosion around the foundation, which can lead to piers collapse.

Intervals: every 50 years

Duration: 20 days

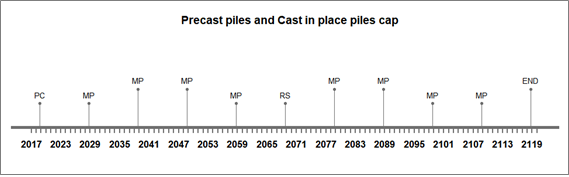

The timeline below shows the interventions along the system lifetime: