Home / Group 2 / Integration Context of the Civil Systems / Water pipe

Introduction

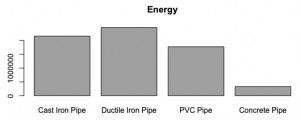

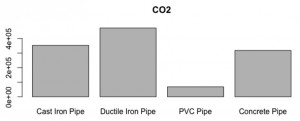

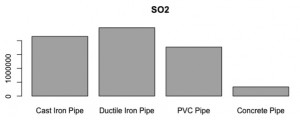

Water pipes are used in water distribution networks to transport raw water from the source to the treatment plant, and to transport the treated water from the treatment plant to the house connections. Pipes are therefore a vital engineering system, as they supply consumers with drinking water. As part of assignment 2 a Life Cycle Analysis was conducted on a 1 km section of water pipe with a nominal diameter (DN) of 200. When comparing pipes made out of the four different materials of PVC, concrete, cast iron and ductile iron, it was determined that the pipe with the least emissions during its lifetime is the concrete pipe. The most important parts of the LCA are presented below.

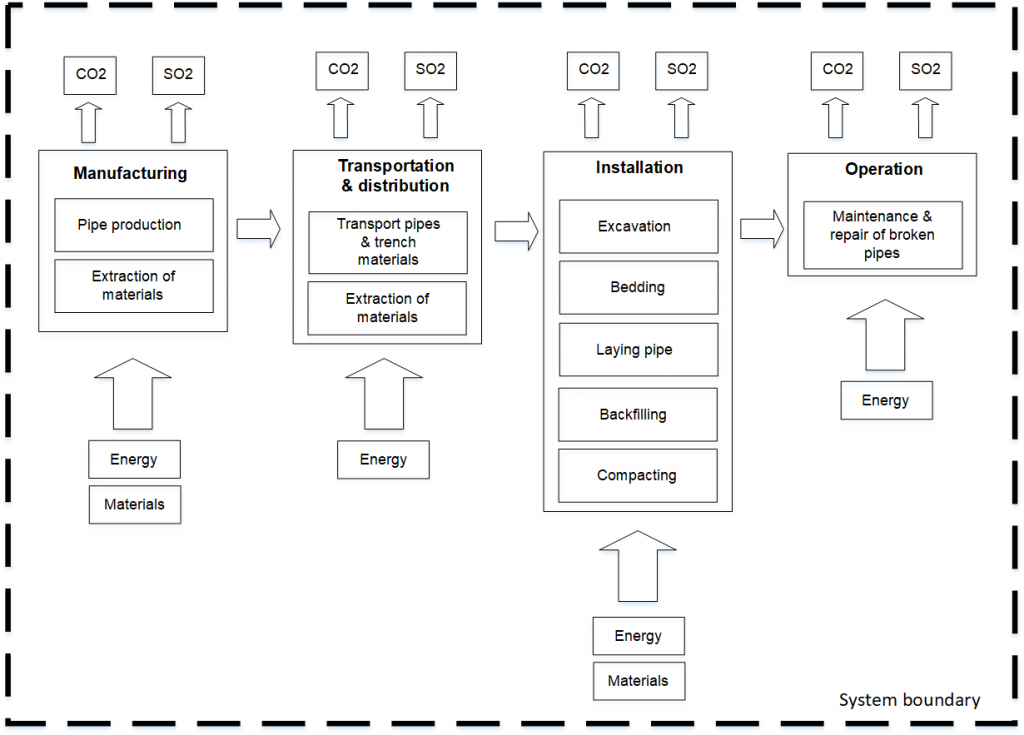

Goal & scope of the LCA

The purpose of the LCA was to determine the environmental impacts of placing a new water supply pipe along a stretch of 1 km. Therefore, the functional unit (FU) was “one km of a pipe of the diameter DN 305”. The study was conducted using four different commonly used materials: cast iron, ductile iron, PVC (Polyvinyl chloride) and concrete. Environmental impacts that were considered are the following:

- Energy consumed (in MJ)

- CO2 emissions (in kg)

- SO2 emissions (in kg)

The above figure presents the system boundary of this LCA. The system boundaries encompass activities in the manufacturing, transportation, installation and operation phases. Recycling and disposal was not considered, as no reliable information could be found on this. Furthermore, this LCA did not consider any of the activities required for the machinery, trucks, etc. used to manufacture, install or transport the pipes. This LCA did however consider the production and transportation, as well as installation, of the bedding and backfilling materials in the trenches. The environmental impacts of the trench filling were considered in the studies that were used for the energy and emissions values for this LCA.

Life Cycle Inventory

The parameters that would be required to calculate the material quantities of the pipe are the following:

- The length of pipe

- The DN (nominal diameter) of the pipe

- The thickness of the pipe material

Furthermore, the depth of the pipe is relevant when it comes to the installation of the pipe and the bedding and backfilling materials required. Here, the assumption is made that all pipes will be installed at the same depth, therefore this point can be taken out of the consideration.

Life Cycle Cost Analysis

The results of the life cycle cost analysis were as follows:

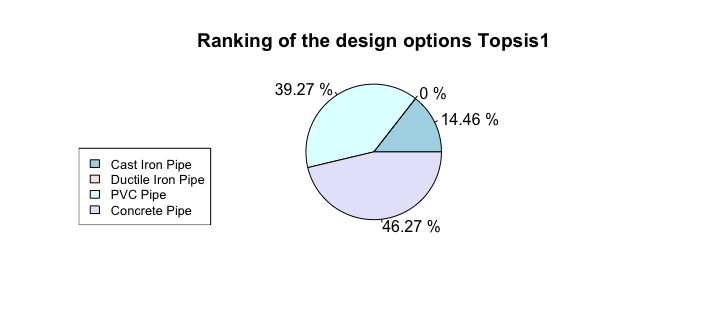

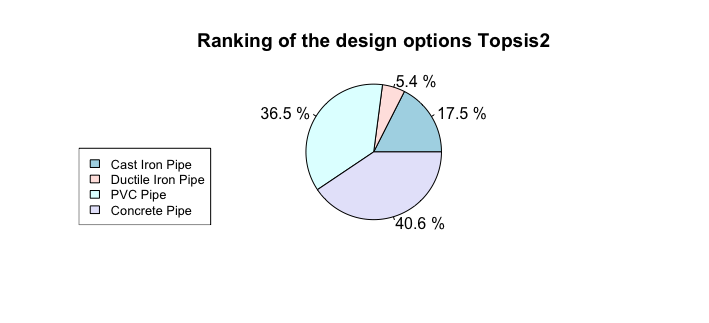

Multi-Criteria Decision Method – TOPSIS

The Technique for Order of Preference by Similarity to Ideal Solutions (TOPSIS) method was chosen to conduct the analysis of the LCA. The indicators were weighted as follows:

- Energy – 0.45

- CO2 – 0.35

- SO2 – 0.2

In order to calculate the ideal positive solution and the ideal negative solution, the four design options were ordered from 1 (lowest amount) to 4 (highest amount) for each indicator. These values were normalized and weighted, and resulted in the following: