Introduction

In industrial building design, the size of storage and work spaces and the consumption of materials required for the structure are crucial. Through parametric modeling, we can quickly generate multiple design options to optimize these two key factors and achieve the high performance of the design goals. This report will utilize Dynamo BIM and Revit 2023 for parametric modeling of a Steel Warehouse. The primary guide is from Poole, Chang, Tolbert and Mellor (2003) and a case study from Goswami & Shende (2018). The purpose is to achieve structural flexibility, material conservation and efficient use of space in warehouse designs through parametric modeling. This report will then specify the structural design challenges and high-performance criteria for assessing warehouse design efficiency. It will discuss the process of the parametric model and then will create three design alternatives. The final section will focus on the alternatives assessment, assessing the effectiveness of the model.

Design Challenge and High-Performance

Criteria The design challenge in this report is to balance maximum utilization of storage and work space with economy of structural materials. To address and simplify this challenge, this report selected two key performance criteria: the size of storage and work spaces, and the amount of material consumed by the main structure (focusing on the column and roof frame).

Design Parameters

The following table shows the key parameters which will directly affect the model and input values.

|

Items |

Purpose | Max value | Min value |

| Width of the warehouse | The width can determine the lateral size of the warehouse and the usability of the work space, but the wider it is, the greater the structural reinforcement required in the lateral direction (the more material is consumed in the lateral structure). | 10m | 100m |

| Height of the warehouse | The height can determine the vertical workable area, but the higher the height means that the vertical stability needs to be strengthened and the material consumption is higher. | 8m | 20m |

| Height of the roof | The height and slope of the roof indicates the size of the workable area at the top, but the greater the slope of the roof, the greater the external environmental load (such as wind load) the structure will bear, requiring reinforcement of the roof structure, resulting in increased material consumption. | 3m | 10m |

| Roof slope | 3

degrees |

15 degrees | |

| Length of the warehouse | The length determines the size of the workable area in the longitudinal direction, but the longer it is, it will lead to the reinforcement of the longitudinal structure and material consumption. | 30m |

100m |

High-Performance Criteria

- Size of storage and work space

Utilizing parametric models, we work to design the internal spatial layout of the warehouse to ensure the most efficient use of space. It is going to focus on the layout and design of the main structure of the warehouse to improve storage efficiency and work space.

- Material consumption

Reduce the material required for a structure through parametric models to improve economy. In this report, aspects such as material selection and structural design will be considered to reduce costs.

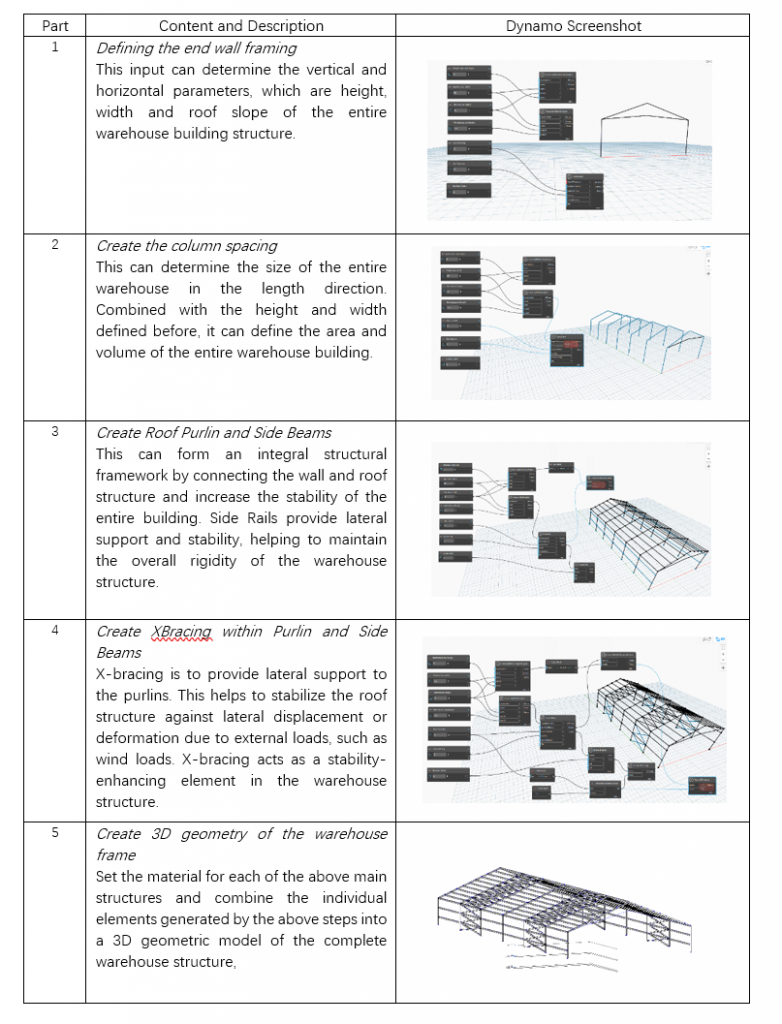

Dynamo Parametric Model

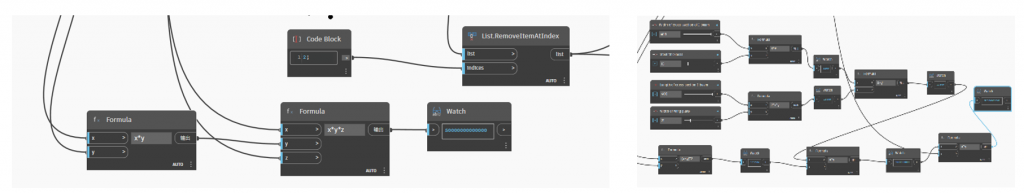

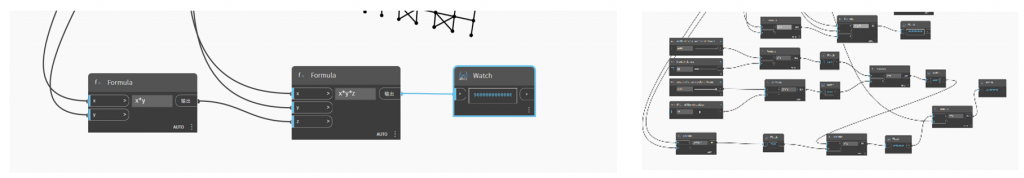

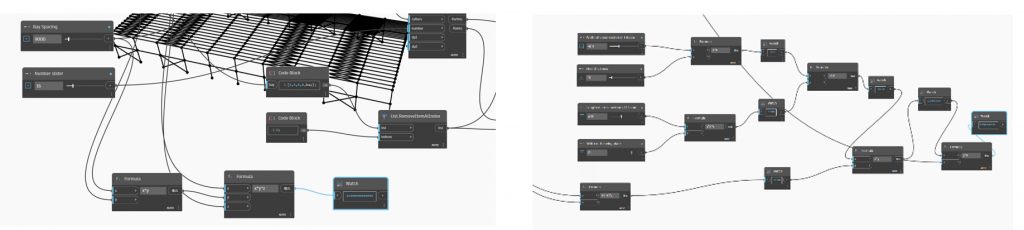

The parametric model building in this report is mainly divided into 5 parts which can be seen as below:

Design space and alternatives

In the design of steel warehouse, the space design is strictly controlled by parameters, such as the size of the end wall, the distance between the columns, the height and slope of the roof, etc. By adjusting the parameters, we can get various design solutions. However, the limit setting of parameters may not be applicable to actual design cases, because actual cases also need to consider issues like structural safety, economy, and energy consumption. Therefore, actual cases and experience will ensure the safety, efficiency and economy of parameter design. Through engineering industry standards and practical experience, this design process will balance structural safety, indoor space usability and material consumption, to meet the goal and constraints of this project.

Experiment and Evaluation

Alternative 1 High-Capacity Storage Warehouse

In order to provide more storage space in this type of warehouse, the length and width are the biggest among all the three design options, but set the Column distance, Purlin Spacing and X-Bracing to the smallest ones to ensure the lengthwise and transverse structural stability. In order to match and coordinate the design of the entire building, the roof height and slope are slightly larger. So, in this option, this model got the biggest indoor volume and also consume the most quantity of steels.

Alternative 2 Workspace-Centric Warehouse

This type of warehouse prioritizes efficient workspace design with moderate storage. For workspace building warehouse design, the overall area of the warehouse should not be too large considering from a safety perspective. So, the width, height and roof slope of the end wall are the smallest ones among the three designs. However, in order to increase the indoor work area, the column distance has been increased to provide an unobstructed work space as much as possible.

Alternative 3 Hybrid Storage-Workspace Warehouse

Balances storage and workspace dimensions with a versatile hybrid design and the indoor space layout is usually required to be flexibly adjusted and changed according to usage scenarios and needs.. Therefore, parameters such as the height and width of the end walls, the roof slope and the total length of the warehouse are set to an intermediate level to allow for flexibility in the mixed use of storage and work spaces. The Column distance is set to the maximum value among the three options to facilitate adjustments to the indoor space (such as adding indoor partitions, baffles, etc.).

The following table shows the values of the two high-performance criteria for the three different design alternatives.

| Option | Width | Height | Roof Height | Roof Slope | Column Distance | Length | Purlin Spacing | Beams Spacing | X-Bracing | Indoor Volume | Steel

Volume |

| 1 | 50m | 10m | 5m | 5d | 5m | 100m | 2m | 5m | 1 brace/5m | 50000 m3 | 52.8 m³ |

| 2 | 30m | 8m | 4m | 3d | 8m | 80m | 3m | 4m | 1 brace/8m | 9600 m3 | 16.72 m3 |

| 3 | 40m | 9m | 4m | 4d | 9m | 90m | 2.5m | 4.5 | 7 brace/7m | 32400 m3 | 21.56 m3 |

References

Goswami, A., & Shende, D. T. (2018). Pre-Engineered Building Design of an Industrial Warehouse . International Research Journal of Engineering and Technology, Volume 05, Issue 06.

Poole, J., Chang, D., Tolbert, D., & Mellor, D. (2003). Common Warehouse Metamodel Developer’s Guide. Indianapolis: Wiley Publishing.