A dam is a structure used to contain water. The purpose of this can be many, but in this system the main functions are infrastructure to cross the river and hydropower production. All dams are made up of several components: The main dam structure which is used to retain the water, the foundation which the main structure is resting on and spillways which are used to release water from above to below the dam. Depending on the dam there can also be culverts or other forms of embedded structures through the main dam structure as well as different adjacent structures, such as a power plant for production of hydropower.

The hydropower production is dependent on the water flow through the dam. Therefore gates are used on spillways and culverts to control the flow rate. There are many types of gates but one component they all have in common is the skinplate, which is the section of the gate which is in contact with water when the gate is closed. The skinplate is usually supported by some sort of structural support system, which means that it doesn’t have to withstand the hydraulic forces on its own. Still, the demands on the skinplate is high.

Table 1: The cost of construction of a structural steel skinplate and the maintenance blast cleaning and painting (BCP)

| Scope | Quantities | Energy | CO2 | NOx | SO2 | Price material | Price work |

| Structural steel | 7800 kg/m3 [1] |

46 MJ/kg [1] |

2560 kg/m3 [1] |

3.08 kg/m3 [1] |

3.28 kg/m3 [1] |

1 €/kg [3] |

50 000 € [5] |

| BCP |

- |

8 MJ/kg [1] |

445 kg/m2 [2] |

0.53 kg/m2 [2] |

0.57 kg/m2 [2] |

20 €/m2 [4] |

10 000 € [5] |

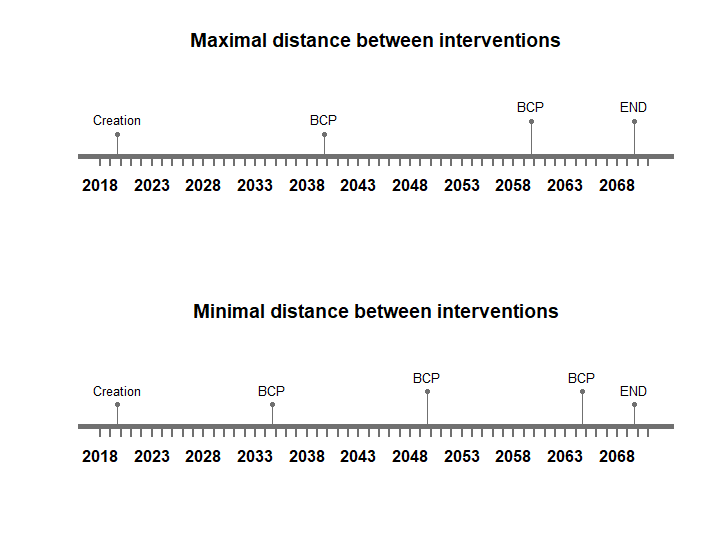

A skinplate made of structural steel have a lifetime of about 50 years. In order to ensure and improve the lifetime maintenance interventions are needed. To keep the water resisting qualities the skinplate needs to be blast cleaned and (re)painted (BCP) every 15 to 20 years [1]. To do this the gate is removed, transported to a service shop, blast cleaned, painted and then put back in its original position, a process that takes five days. This maintenance, as well as the construction, is of course associated with certain costs, both monetary and environmental (table 1). Neither the maintenance or the new-construction should therefore be done more often than necessary (figure 1).

Figure 1: Maximal and minimal distance between interventions

The above maintenance plans are only based on the gate. It is important to see the gate as part of a bigger system and implement an integrated maintenance planning strategy. During the maintenance of the gate(s) the hydropower production will be affected and it is therefore wise to have some other form of electricity production running during these times, for example wind turbines. The function as transportation across the river will also be affected during some gate maintenance, since the infrastructure will be (at least partly) blocked by the maintenance workers and their equipment. This will therefore result in an increased demand on other infrastructures connecting the two riversider, such as tunnels.

[1] Daniel, R. & Paulus, T. 2019. Chapter 12 – Sustainable Gate Design. Lock Gates and Other Closures in Hydraulic Projects. Elsevier Inc.

[2] Based on the assumption that the environmental cost follow the same relationship as energy.

[3] SpendOnHome. 2020. How Much Does Structural Steel Fabrication Cost?

[4] Dennis, D. & Gleason, C.P.E. 2017. 2018 National Painting Cost Estimator. Craftsman Book Company.