Highway tunnels are essential structures in crowded metropoles they solve many traffic problems and save a lot of time in the traffic especially in big cities they have the same importance as bridges. the basic material to build them is concrete or a combination of the steel and concrete. As every concrete structure the reinforcement of the tunnels gets also affected with the time Due to Chloride brought with the cars , as well as carbonatation of concrete which is a big find for the lifetime of the concrete and the armed concrete as well , and also in some cases weather changes could lead to structural failure.

Other than structural failure, in the paper ‘Life Cycle Management Model for Tunnels’ [1] is mentioned that the primary phase of the actual construction process of a tunnel is excavation which leads to stress redistribution and changes in soil stiffens. This eventually leads to short-term and long-term deformations that can cause local cracks or micro cracks on the concrete lining surface also fire is a big problem in tunnels.

There are many ways to determine the degradation in concrete structures, in his lectures Professor Dr. Dietmar Stephan from the Technical University of Berlin based on the book Wendehorst Baustoffkunde mentioned that the best way to determine the situation of concrete and how affected the reinforcement is, is by crack depth monitoring. Hammer test and ultrasound.

on of the most famous Tunnels in the World is the Longest road Tunnel the Laerdal Tunnel in Norway . In June 1992, the Norwegian Parliament decided to construct the world’s longest road tunnel. The 24.5km-long stretch of tunnel stretches between Aurland and Laerdal on the new main highway connecting Oslo and Bergen.

on of the most famous Tunnels in the World is the Longest road Tunnel the Laerdal Tunnel in Norway . In June 1992, the Norwegian Parliament decided to construct the world’s longest road tunnel. The 24.5km-long stretch of tunnel stretches between Aurland and Laerdal on the new main highway connecting Oslo and Bergen.

The construction was approved to traverse a section of the country with relatively poor levels of reliability in road transport due to the mountainous area and narrow roads combined with many fjord crossings.

The Laerdal tunnel is an important part of the extension of a ferry-free, reliable road link between the two largest cities in Norway. The decision to build a tunnel rather than refurbish existing roads was taken to avoid difficult terrain with high risks of rock falls. From an environmental perspective, the tunnel was seen as a justifiable investment to avoid destroying sections of the unspoiled natural landscape.[2]

Subsystem : Tunnel Wall

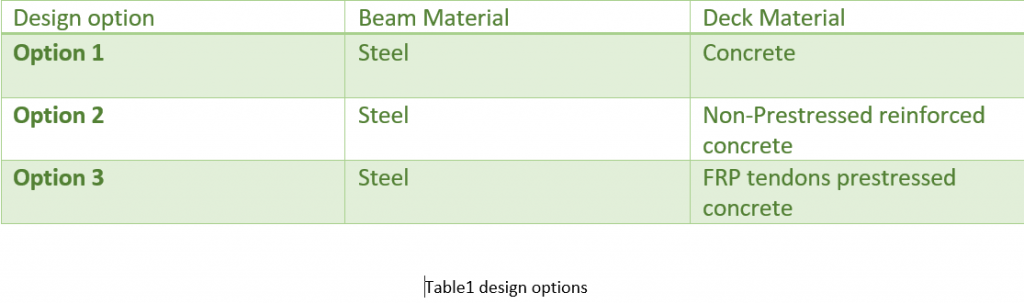

Design Options

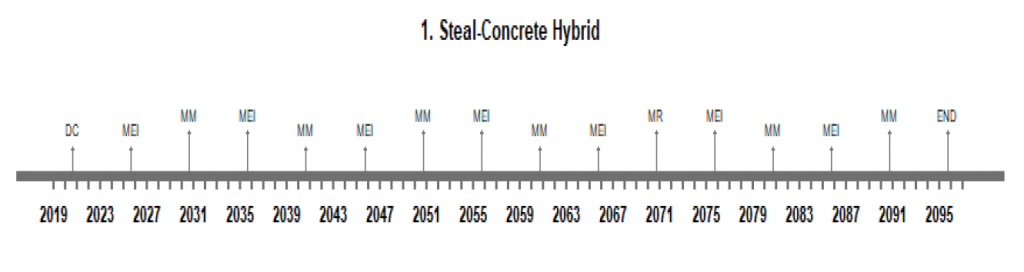

Life Cycle Timelines

as mentioned before there are many environmental factors cause deterioration of the tunnel superstructure . These factors affect the tunnel wall in various ways and reduce the safety which means also a huge amount of costs. the consideration of maintenance and repair of the tunnel is mandatory To maintain a safe state for the tunnel and to estimate the life-cycle cost of tunnel wall. These interventions keep the tunnel condition in a good state. The interventions include Main external inspections, Minimal Maintenance (MM) and Major Rehabilitation (MR).

The initial design life of the tunnel was determined as 70 years. Main inspections will be implemented every 5 years, steal concrete slabs need Minimal Maintenance (MM) every 10 years and Major Rehabilitation (MR) each 50 years. The resulting timeline for the chosen option is shown below.

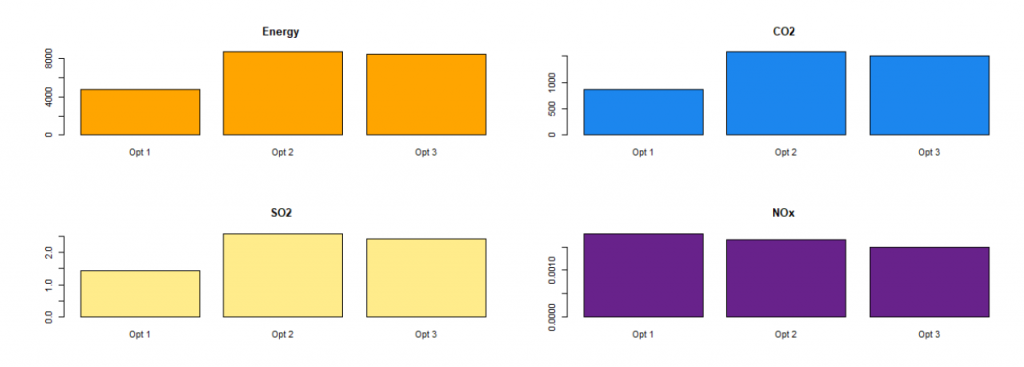

Life-Cycle Inventory

from the Life -Cycle Inventory we cann see that the design option 1 is the best design of the 3 designs

[1] Life Cycle Management Model for Tunnels Sandra Škaric Palić, Irina Stipanović,

Meho Saša Kovačević, Kenneth Gavin

[2] https://www.roadtraffic-technology.com/projects/laerdal-tunnel/