With the rising need of faster surface transport, diverting roads away from rough terrain is no longer an option. This is where the need for Viaducts come in. In this ontology is developed to represent the conceptual design of Viaducts with respect to structural components.

Viaduct is a specific type of bridge that consists of a series of arches, piers, or columns supporting a long-elevated railway or road. The viaduct connects two points of equal elevation allowing passage over a valley, road, river, or other low-lying feature or obstruction. Prestressed concrete is a concrete that is prestressed so that the induced internal actions counteract the external loading to a desired degree. Prestressed concrete members can be placed in one of two categories: pretensioned or posttensioned. Here we will see the deterioration of a Prestressed Concrete Viaduct during the lifetime.

one of the most famous Viaducts is the Millau Viaduct in France Surpassing even the mighty Eiffel Tower in height, France’s Millau Viaduct holds the current title of the tallest bridge in the world. Rising up to 343 metres, the bridge opened in 2004 and straddles the Tarn Valley between Clermont-Ferrand and Béziers and Narbonne. For a different view of the statuesque structure, bridge enthusiasts can canoe underneath.

Many bridges all around the world experience very hard climatic conditions, and due to the irregular maintenance effort, show different problems of cracking, concrete cover detachment and steel reinforcement wear and corrosion. In general, as a consequence of the polluted rain wetting, the problem is more evidentin vertical structures than in the horizontal ones, and serious problems can arise when the piers and columns are very tall.

so this why a Crash Barrier repair and Minor maintenance in an ideal frequency should be done every 10 Years and Replacement of Crash Barrier every 20 years , Guard Barrier repair and Minor maintenance in a min frequency every 5 years and Replacement of Guard Barrier every 15 Years

Subsystem : Barriers

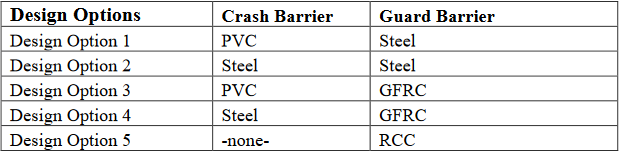

Design Options

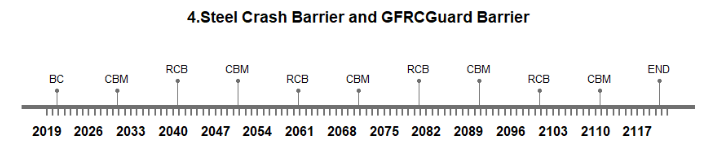

Life Cycle Timelines for design option 4:

CBM -Crash Barrier repair and Minor maintenanceevery 10 years

RCB -Replacement of Crash Barrier every 20 years

GBM -Guard Barrier repair and Minor maintenance every 10 years

RGB -Replacement of Guard Barrier every 20 years

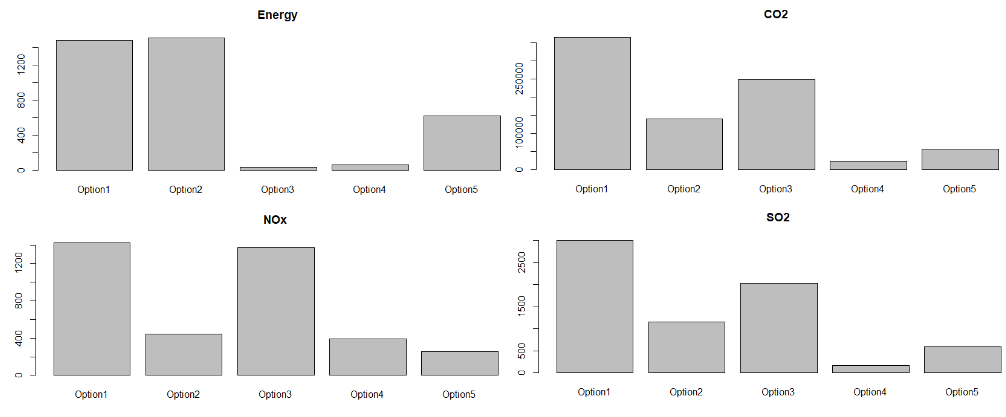

Life-Cycle Inventory

From the Life -Cycle Inventory we cann see that the design option 4 is the best design of the 5 designs