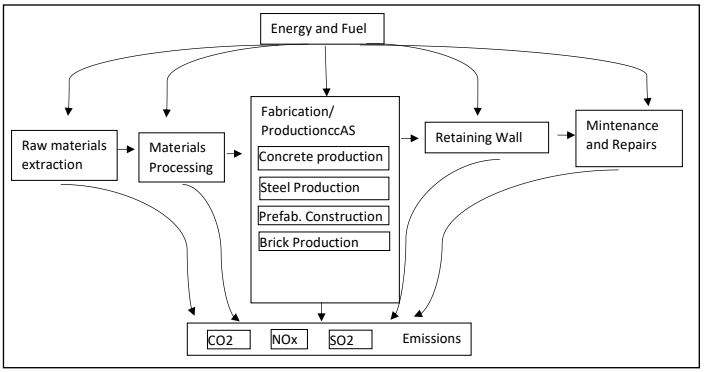

Making decisions to choose materials as well as configuration of operation and maintenance activities by considering the impact on the environment is a complicated task for engineers. This decision-making process requires an advanced visualization and simulation of possible solutions to the problem. In this assignment, life-cycle assessments of three different stadium retaining wall designs are conducted to understand the total amount of greenhouse gases (CO2, NOx, SO2) emissions and energy consumed during the life cycle of each design options. Then the most environment friendly design option among them is chosen. This retaining wall is used support audience stand and the earth beneath. Only one side, which is near the long edge of the pitch, of the rectangular stadium is considered in this assignment as shown below.

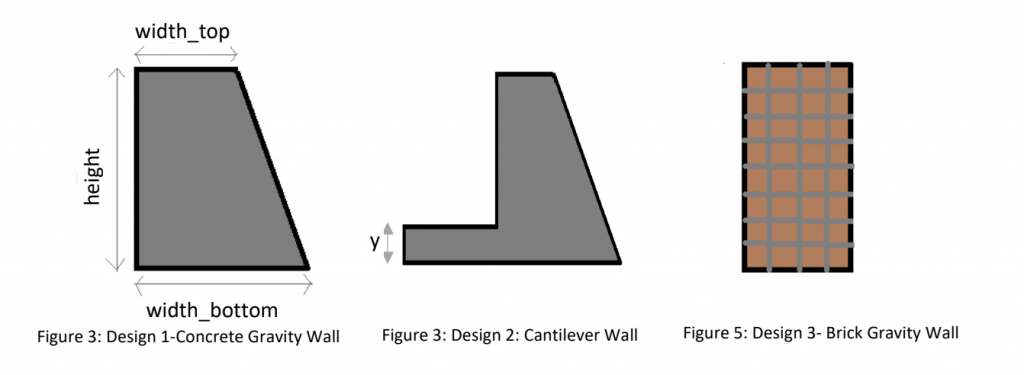

As it is seen from the figures given above, shape of the wall changes with respect to both wall type (gravity or cantilever wall) and wall main material (prefabricated concrete and brick). To calculate cross sectional area of the first design, trapezoidal are formula is used with the given values. 1 m3 concrete is almost 3 times heavier than 1m3 brick. Since gravity walls carry the load specifically according to their own weight, while giving dimensions to the 3rd design, a ratio closer to 3:1 with respect the first design is targeted to determine the width_bottom parameter. Cantilever wall has steel reinforcement inside on the contrary of the other design options. Also, it has a thinner stem since it uses the weight of the material above heel part to resist the overturning moment. Due to these, it can provide higher resistance with less cross- sectional area. Therefore, height in the first design decreased by %33 and additional heel part is added.