Summary of Dynamo Design Process

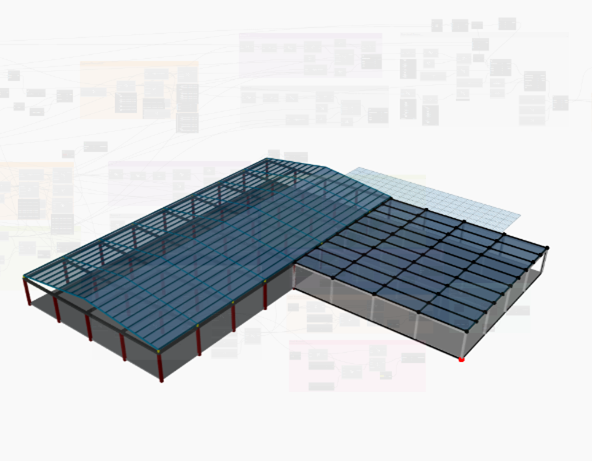

The following parameters were selected as the ones to control the parametric model:

Depth (L) and width (W) of the warehouse define the overall size and footprint of the warehouse, which is critical for planning the storage capacity, internal logistics, and layout. They also influence the design of structural elements like beams, floor and columns to ensure they can support the roof and any upper levels. Apart from these, that parameters helped to defining our warehouse shape which is I-shaped layout in our example. In that type of layout, the products are arranged so that the higher-volume items are easily retrievable [1]

Column height determines the vertical space available for storage and the operation of equipment like forklifts. It most importantly impacts the volume of goods that can be stored and the types of racking systems that can be used. Thus, while designing that parameter in dynamo rack height, sprinkler and clear height is considered. Distance between columns affects the open floor space and layout flexibility. Wider spans can accommodate larger equipment and uninterrupted storage systems but may require stronger structural support.

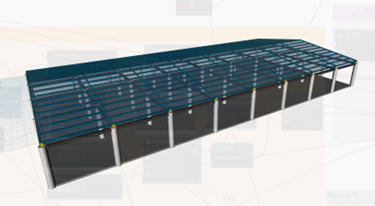

Another parameter that we can adjust and influence other parameters is roof’s structural frame angle and height. That parameter can influence the ability to collect rainwater, the potential for installing systems like solar panels, and can affect the interior temperature regulation of the warehouse.

In fact, since we don’t consider structural analysis for now of the model this parameter has no impact apart from visualization in that moment. However, according to UFC, floors in warehouse facilities must be no less than 6 inches (150 mm) thick, and that parameter is implemented to the design. Also, in multi-story warehouses, the floor height impacts the stacking capability and the ease of movement between levels.

Another parameter that we can adjust and influence other parameters is roof’s structural frame angle and height. That parameter can influence the ability to collect rainwater, the potential for installing systems like solar panels, and can affect the interior temperature regulation of the warehouse.

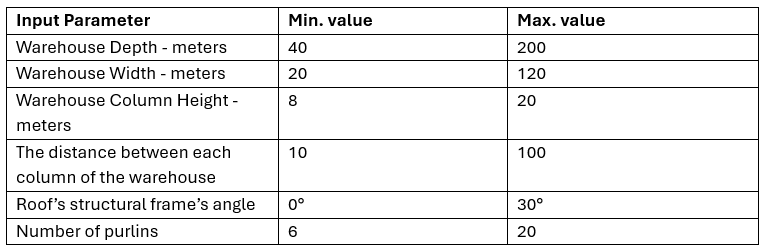

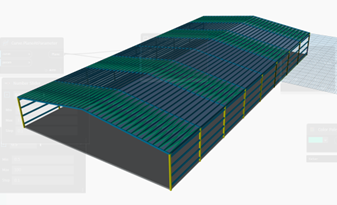

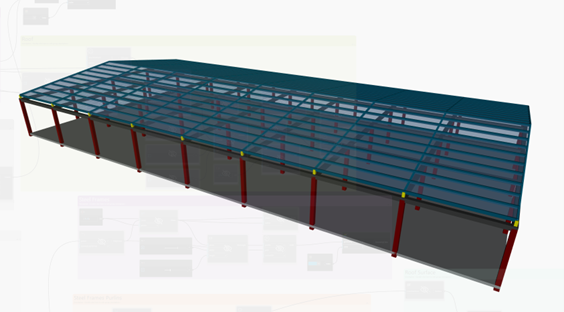

Although the initial design did not include layout variations, several variables have been added to evaluate and visualize the parametric model. As there are several options such as U-shaped, I-shaped, and L-shaped, the layout of the warehouse was changed. I had originally designed the warehouse with an I-shape, but I also created an L-shaped warehouse for comparison purposes. I used the same values as before, but with a different roof angle for the additional section.

In addition to being able to adjust the input values, I have implemented the option to switch the design from concrete columns to a steel frame structure consisting of wall bracing, roof bracing, and side rails in addition to the initial roof design. If necessary, the shape of the columns can also be changed using a Boolean node in the dynamo model.

As a high performance criteria, two options are determined which are storage capacity and solar panel potential energy generation. Due to the inherent of the design and operational purposes we cannot allocate the entire building to storage. In such designs apart from shipping, staging, and receiving areas, an emergency exists, aisles, toilets, and offices must be considered. However, in our model, we are compelled to keep it as simple as possible. Therefore, some percentage of the building is allocated to shipping, staging, and receiving areas. In the middle of the building will be utilized for storage. In order to provide insight into later projects we can calculate storage capacity by utilizing from our generated input parameters. In order to calculate solar panel potential energy generation, average solar panel efficiency and the typical amount of sunlight values are determined to estimate how much power we could get. With this, we can make the warehouse eco-friendlier and maybe even send some power back to the grid. To do so, the roof surface area is calculated and multiplied by the usable percentage.