With the aim of electrification of the railway system, the power supply for 39km of railway lines is required.

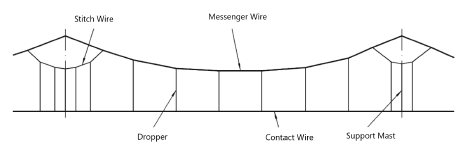

The subsystem chosen for the life cycle analysis is the pole from the overhead catenary system, which can be seen in the picture below as a support mast.

The poles withstand all forces acting on them and transmit them to the foundation. These can be the weight of the catenary, the tensile forces with which the catenaries retightened, but also the wind forces, aerodynamic loads acting on catenary, and supporting equipment.

The picture below shows the pole structural design:

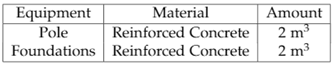

Geometry and materials

In this case the pole is a conical spun made of concrete, which is well suited for high-speed lines due to their high load-bearing capacity. Spun concrete is reinforced with pre-stressed steel (longitudinal and spiral). They have a circular cross-section and a cavity in the center that extends from top to bottom.

For one spun concrete mast the following materials are used:

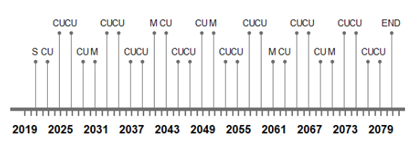

Maintenance interventions

The lifetime of the system is defined as 60 years. Due to its inherent characteristics there is almost no need for maintenance over the life time, in major cases replacement is more suitable. The pole structure and foundation is inspected every 24 month. Maintenance repairs, such as small cracks in the concrete, are fixed every ten years.

1. Inspections

Description: Regular preventive visual inspection of pole structure and foundation

Intervals: every 1 year

Duration: 2 days

2. Repairs in the foundation

Description: Repair of cracks

Intervals: every 10 years

Duration: 10 days

3. Repairs in pole structure

Description: Repair of cracks

Intervals: every 10 years

Duration: 5 days

The timeline below shows the interventions along the system lifetime:

— I WOULD NOT INCLUDE THIS—

Extension of the Railway Power Supply System

Project Information System (PRINS in German) for the Federal Transport Infrastructure Plan 2030

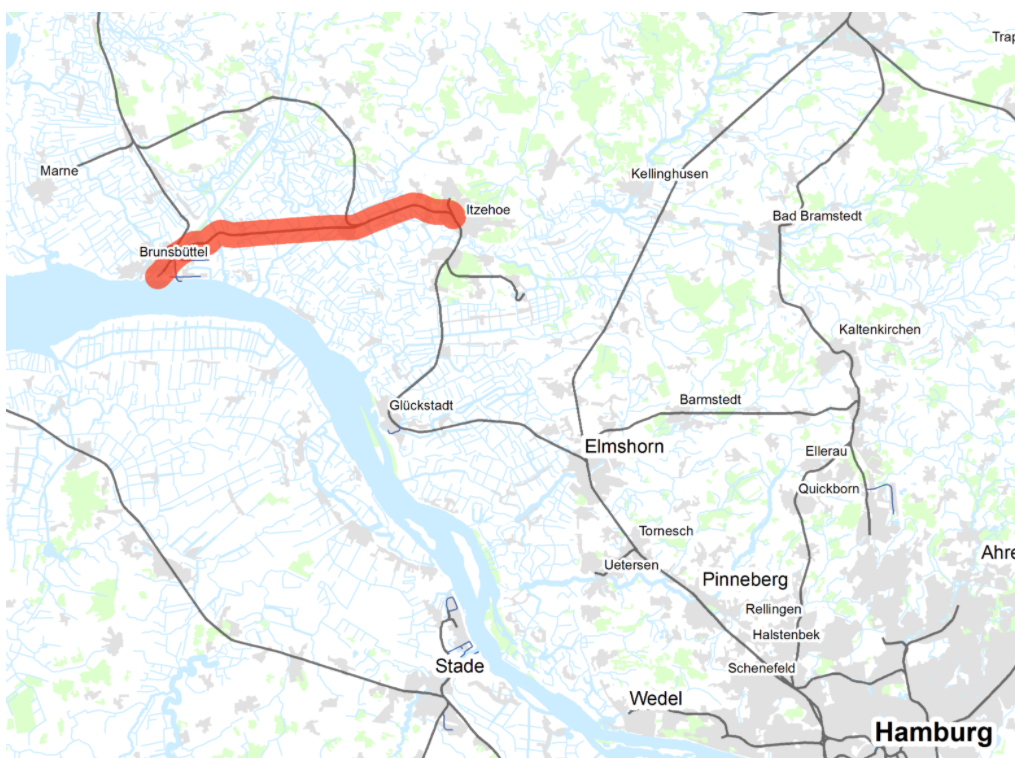

To improve the port connection of Brunsbüttel, electrification of the Wilster – Brunsbüttel rail line from Wilster to a new transfer station to be built between DB Netz AG and ChemCoast Park Brunsbüttel in the area of the former Landscheide station is planned. The supplementary electrification of the Marschbahn in the Itzehoe – Wilster section will allow freight trains to/from Brunsbüttel to be continuously electrified without reloading in Itzehoe.

Project overview:

- Electrification Itzehoe – Wilster,

- Electrification Wilster – Brunsbüttel transfer station

- Total Length 39.0 km

- 32.0 € Total investment costs

- 4.9 Mio. € Outstanding planning costs for expansion and new construction

- 27.1 Mio. € Expansion and new construction costs

Reasons for the Extensions:

- Low Benefit Cost Relationship,

- no high environmental impact,

- closing electrification gap and

- transportation cost reduction.