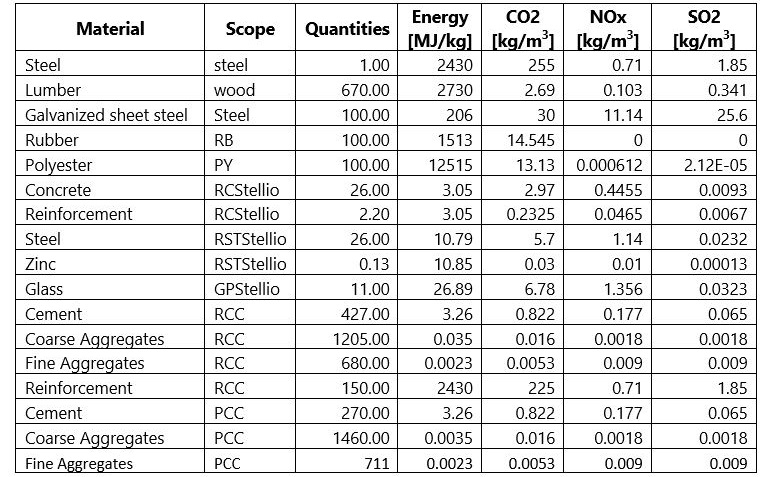

During the LCA, the focus was set on the subsystem’s materials and lifetime to study the final effects on the environment. In Fig. 1 the assessment’s boundaries and scope are represented. Thus, taking the processes of raw material extraction, material processing and fabrication as well as the construction of every single system into consideration, while calculating the different associated emissions. These emissions were carried out “from cradle to gate” and include considerations for repairs and interventions.

Fig.1: Definition of scope and boundaries for the assessment of the Integrated System

Fig.1: Definition of scope and boundaries for the assessment of the Integrated System

Four subsystems of four main systems were integrated to form a new joint structure, by which it is necessary to integrate the life cycle inventory of all the individual subsystems to one. The life cycle inventory was made while keeping in mind the scope and goal within the specified boundary, as described earlier.

As mentioned in the introduction, the main goal of this assignment is to reduce maintenance time and increase the time between interventions on the integrated system. The LCA and the related study of the effect of each maintenance action and its duration on the environment throughout an integrated lifetime of 50 years represents the basis for the Multi-Objective Optimization as well a recommendation for an integrated maintenance strategy.

In the following, the required materials of each subsystem for the LCA are summarized

- Main System: Flour Factory

- Sub System: Frame

- Best Design Option: Wooden frame with steel bracing

- Materials Required: Lumber and steel

- Main System: Mechanical Ventilation System

- Sub System: Heat exchanger

- Best Design Option: Xpelair with galvanised sheet steel as a cover, rubber seals for insulation and G4 polyester as a filter material

- Materials Required: Galvanised sheet steel, rubber and polyester

- Main System: Solar Power Tower Plant

- Sub System: Heliostats

- Best Design Option: Stellio with reflecting surface of prefab glass panes, radially arranged steel truss as supporting structure and cast in place reinforced concrete for grounding.

- Materials Required: Concrete, reinforcement, steel, zinc and glass

- Main System: Single Storey House

- Sub System: Foundation

- Best Design Option: RCC Isolated footing with a PCC cap

- Materials Required: Cement, coarse aggregate, fine aggregate for both PCC and RCC as well as reinforcement for RCC

Based on the required material amounts of each subsystem, the values for the energy demand and greenhouse gas emissions as well as environmental costs are calculated. The frequency of intervention during the common lifetime of 50 years were obtained by the timelines considered for the integrated maintenance strategy. In order to include the impact of these frequencies, the output values are multiplied with the values of the frequency for a subsystem. An example is given in the following for the Wooden Frame.

Fig.2: Example of the calculation of total energy demand for the Wooden Frame and an intervention frequency of 7 for the wooden frame and 1 for the bracing

A common length and width are chosen as standard measures for the integrated system. For a uniform comparison and to make the calculation of the environmental impact possible, a specific factor is introduced, thus leading to realistic dimensions of each subsystem. A detailed example is given here.

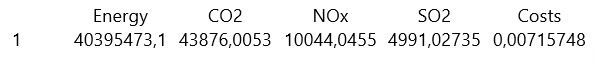

Finally, an inventory is formed that sums up the material emissions and energy consumption shown in Tab.1.

Tab.1: Material inventory of the Integrated System

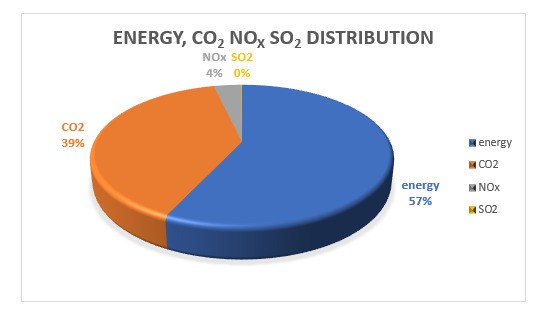

To consider the total amount of energy demand, emissions and costs of the integrated system, each subsystem’s emissions were combined into one dataframe (see Fig.3). To keep things uniform, the same cost per metric tonne for evaluating the environmental impact monetary are set for all subsystems.

Fig.3: Result of LCA – Total amount of energy demand, greenhouse gas emissions and costs for the integrated system

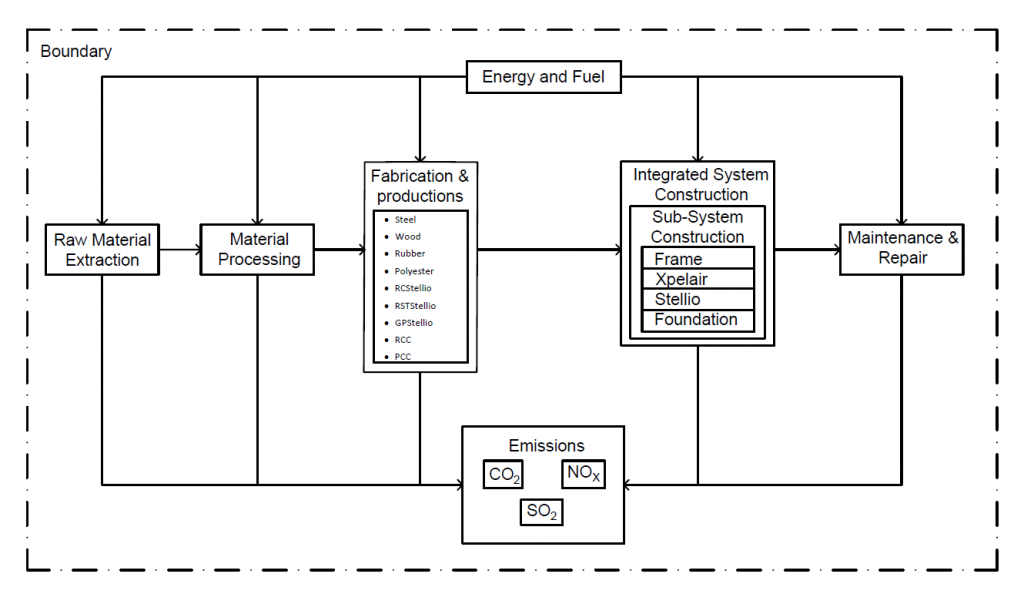

The substructure’s emissions and energy consumption are displayed in Fig.4. It can be stated that the main environmental discharge of the system is its energy consumption of 57% and CO2 emissions of 39%.

Fig.4: Result of LCA – Energy and emission proportion of the Integrated System

Page Navigation

3. Life-Cycle Inventory Analysis