Decision-making is based on the availability of information, assumption, communication and, computation. Making the right decisions plays a crucial role in creating a competitive and functional product and decisions are made at different levels of an organization: strategic, organizational, and technical [4]. Designing an engineering product requires the consideration of many different options. Design support tools enable the process of obtaining optimum solutions such as the most appropriate choice of material for the component of a product.

The Selected Subsystem: Deck

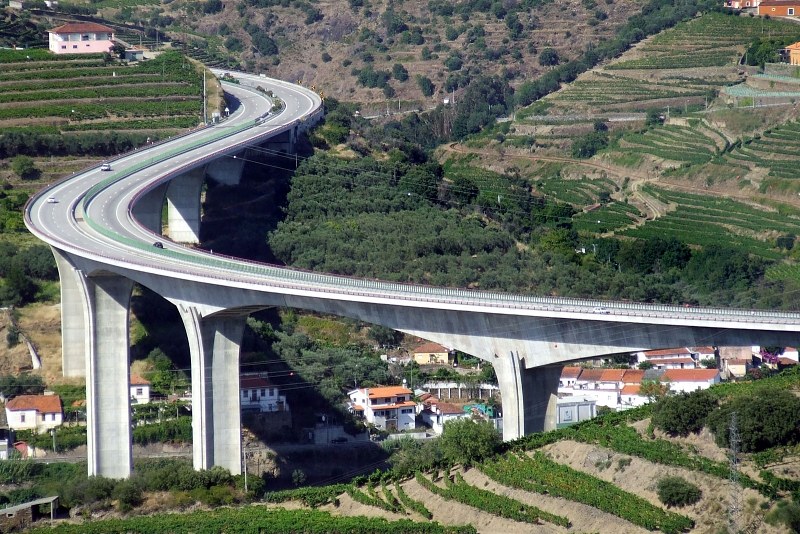

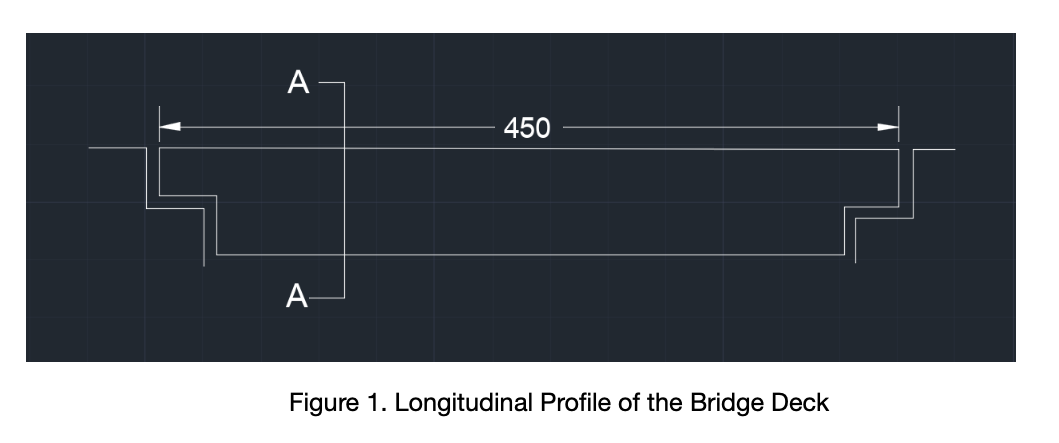

In this report, life-cycle impact and multi-criteria decision analysis of a multi-lane highway bridge are evaluated. The chosen system is providing a passage over a river bed, it has 6 spans, a total length of 450 m and 12 m in width. Since the bridge super- structure contains the most important part of the total material use of a bridge, only the bridge deck and its supporting features will be considered. The superstructure of the bridge has a hollow trapezoidal cross-section to support the long span length. The longitudinal profile of the bridge deck is shown below:

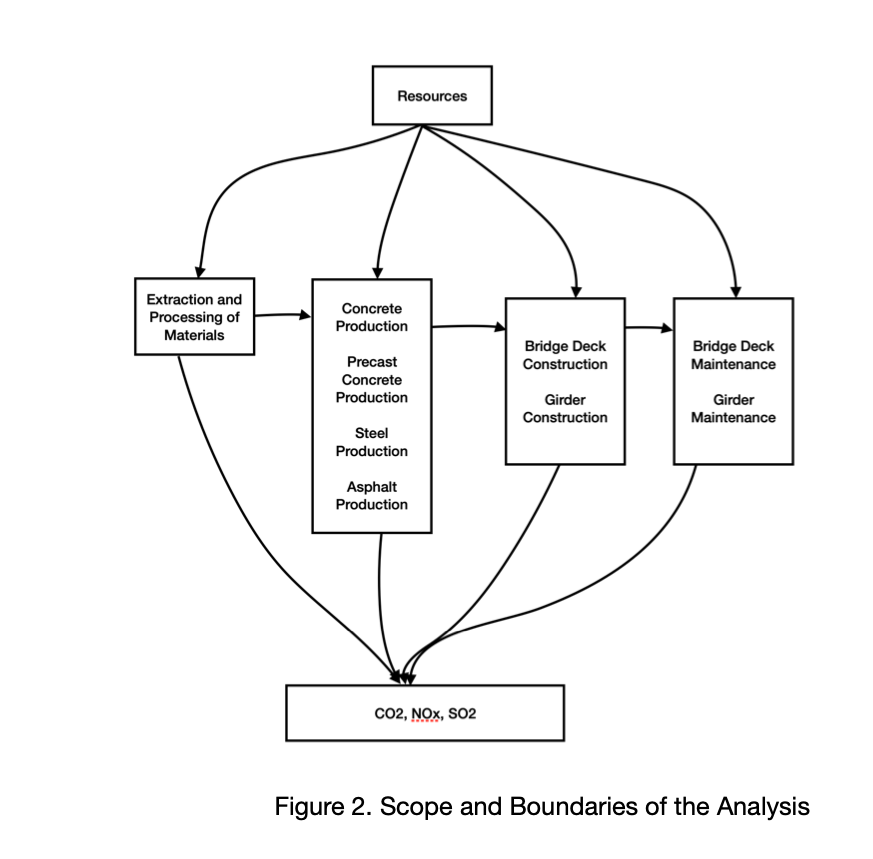

The goal of this analysis is to guide decision-makers in selecting or managing materials or operations that will minimize environmental impacts while furthering maintaining a relatively low life-cycle cost. The scope of the analysis is as below:

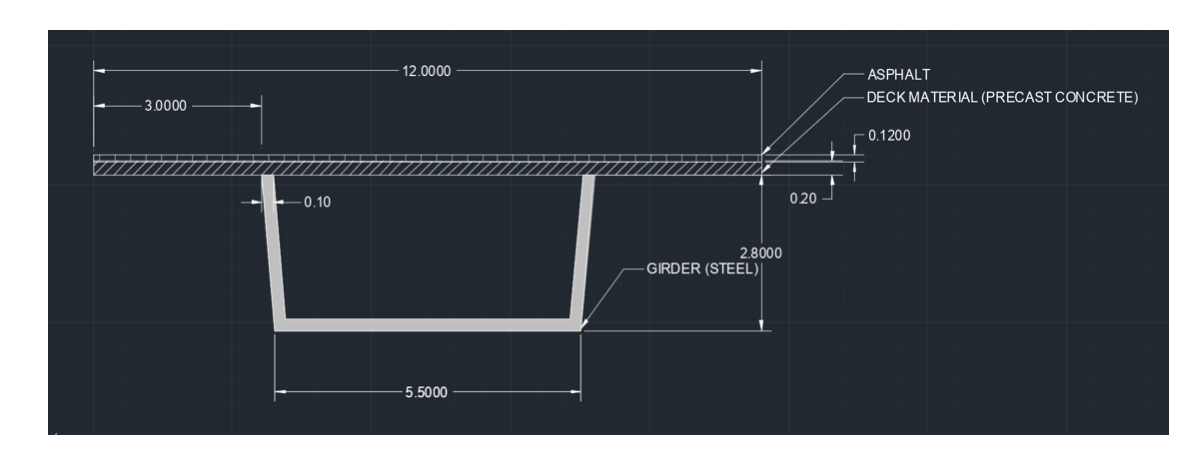

The second stage of LCA is the life cycle inventory (LCI). In this stage, the life cycle inventories are made by quantifying the material and energy consumptions or transformations included during the lifetime of a product. To quantify these, certain pa- rameters should be defined such as dimensions, spans, unit weights, etc., [4]. The cross-section of the deck is shown in Figure 1. The thickness of the slab and girder is not indicated since it is going to change with different material options. Other parame- ters are as below:

Total deck length: 450 m Steel unit weight: 7850 kg/m3

Design Options

Three design options are considered for the superstructure of the bridge. A hollow trapezoidal section is selected to provide more support for long spans. For the same reason, girder material is chosen as steel for all three options but deck materials vary.

|

Design option |

Girders Material |

Deck Material |

Deck surface |

|

Option 1 |

Steel |

Steel |

Asphalt |

|

Option 2 |

Steel |

Cast in place Concrete |

Asphalt |

|

Option 3 |

Steel |

Precast Concrete |

Asphalt |

Table 1. Options

|

Element |

Cross Section Area (m2 ) |

Material |

|

Steel girder (871,35 kg/m) |

0.111 |

S355J0WP |

|

Steel Deck (9420 kg/m) |

1.2 |

S355J0WP |

|

Cast in place concrete deck |

2.4 |

20 MPa |

|

Prefab concrete deck |

1.6 |

50 MPa |

|

Asphalt(thickness = 0.12m) |

0.144 |

Asphalt |

Table 2. Material Properties

Several environmental factors cause deterioration of bridge superstructure as discussed in detail in the previous report. These factors affect the bridge deck in vari- ous ways and reduce safety. To maintain a safe state for the bridge and to estimate the life-cycle cost of bridge decks correctly requires the consideration of maintenance and repair activities. These interventions keep the bridge condition above the risky limit states. The interventions include annual simple visual inspections, main inspections, deck replacements, and girder replacements [2].

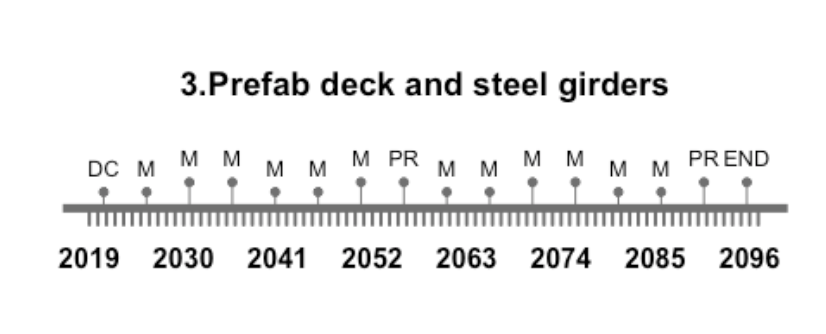

The initial design life of the bridge was determined as 75 years. Main inspections will be implemented every 5 years, shallow deck replacement every 15 years, deck re- placement every 25 years, and girder replacement every 35 years. The resulting timeline for the chosen option is shown below.

Figure 4. Cross-section of the Chosen Option

Life-Cycle Inventory

Different amounts of materials are used for different deck options. This is caused by both the use of different materials and different frequency of interventions. 628 m3 of asphalt and 3921 tons of steel for girders are the common quantities for all three op- tions. Quantities of deck materials vary as below:

Option 1: 4239 tons of steel

Option 2: 1620 m3 of cast in place concrete

Option 3: 1085 m3 of precast concrete

Life Cycle Cost Analysis

LCCA is evaluating all costs of a product during its life cycle. These costs are classified as direct and indirect. The direct cost consists of engineering, construction, and all kinds of maintenance costs. The indirect cost includes economic and social im- pacts like pollution or disturbances resulting from repair activities. It is crucial to include indirect costs in life-cycle cost [3]. Numerous material prices are found and the average prices are estimated below. By using these prices, the life cycle costs of three options are estimated. Regular maintenance activities are not included.

Steel: 900 USD/ton

Cast in place concrete: 45 USD/m3 Precast concrete: 350 $/m3 Asphalt: 150 USD/ton

Option 1: In the initial construction, 1458 tons of asphalt, 3921 tons of steel for girders, and 4239 tons of steel for the deck are used. The steel deck will be replaced in the mid-life of the bridge. The total initial construction cost is 7,562,000 USD. The cost of mid-life replacement is 7,344,000 USD. The total life cycle cost is 14,906,000 USD.

Option 2: In the initial construction, 1458 tons of asphalt, 3921 tons of steel for girders, and 1620 m3 of concrete are used. Based on the timeline of the option, the to- tal maintenance cost throughout the lifetime is estimated. The total initial construction cost is 3,820,500 USD. The cost of all maintenance activities is 4,622,400 USD. The to- tal life cycle cost is 8,442,900 USD.

Option 3: In the initial construction, 1458 tons of asphalt, 3921 tons of steel for girders, and 1085 m3 of precast concrete are used. Based on the timeline of the option, the total maintenance cost throughout the lifetime is estimated. The total initial con- struction cost is 3,820,500 USD. The cost of mid-life replacement is 3,820,500 USD. The total life cycle cost is 7,641,000 USD.