Home / Group 2 / Integration Context of the Civil Systems / Concrete gravity dam

Introduction

A dam is defined as a kind of barrier used to regulate water flow and store it behind that barrier. Collecting water by using dams is one the most efficient way to manage water resources which are used for ages. Hence, dams are being an important subject for storage and future distribution. They are built for several purposes, including flood control, irrigation, hydropower, water supply, and recreation. Dams can be classified in many ways, depending on their size, materials, structural types, construction methods, etc. Dams can be classified as earth fill or rockfill dams, concrete dams, masonry dams, and timber dams based on the materials used. Depending upon structure and design, dams are classified into gravity dam, arch dam, buttress dam, and embankment dam.

The life span of concrete gravity dams can be divided into natural life span, environmental life span, and economic life span. The natural life span mainly lies in its conditions of dams. Because of structures, materials, earthquakes, floods, or other reasons, some dams may become defective and need to be rebuilt, disused, or removed, which can be considered to reach their natural life span. For those which are breached due to natural reasons (excluding wars or terrors, etc.), it can also be considered to have reached their natural life spans. The service life of a well-designed, well-constructed, and well-maintained and monitored embankment and concrete dams can easily reach 100 years. Hydromechanical elements such as gates and their motors have to be replaced after 30 to 50 years. The lifespan of penstocks is 40 to 60 years.

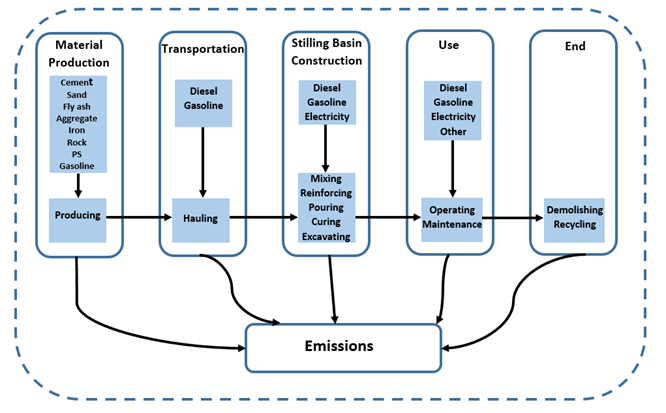

Life cycle assessment (LCA) is a systematic tool for analyzing and evaluating the cost and impacts over the entire life cycle of a product or system or service from “cradle to grave”. LCA involves tracing of all the major stages and processes involved over the life cycle of a product or system or service covering. The impact due to extraction of raw materials, manufacturing, product use, recycling, and final disposal needs to be identified and quantified at each stage. The most important parts of a dam’s life cycle are the operation and maintenance stages. The objective of this project is to evaluate the environmental loads of a dam’s lifetime, and to quantify the environmental impact of four different construction methods.

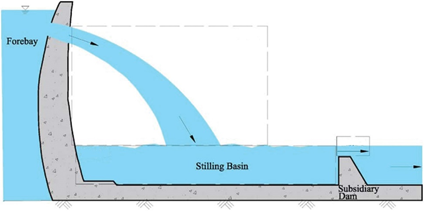

Component : Stilling Basin

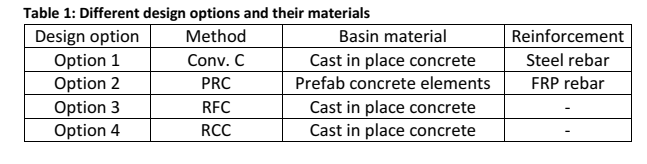

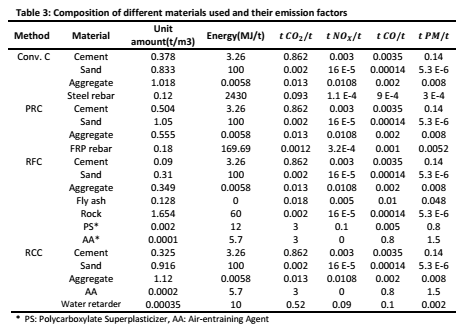

Dams require a high-volume of construction materials and operations over the life cycle. This project aims to select a proper type of dam structure that can significantly contribute to the sustainability of dam projects. Conventional Concrete (Conv. C), Precast reinforced concrete (PRC), Rock-Filled Concrete (RFC) and Roller-Compacted Concrete (RCC) are four dam construction methods evaluated on the construction of the stilling basin(a component of a dam) in this project as shown in Fig 1. The awareness of the difference between these methods could be helpful for decision-makers in selecting more environmentally responsible dam construction methods.

The boundary for the LCA study is set for material production, transportation, operation, and maintenance, which is described in Fig. 2. Materials in this study include all of the concrete and steel compositions and fossil fuels.

Life-Cycle timeline

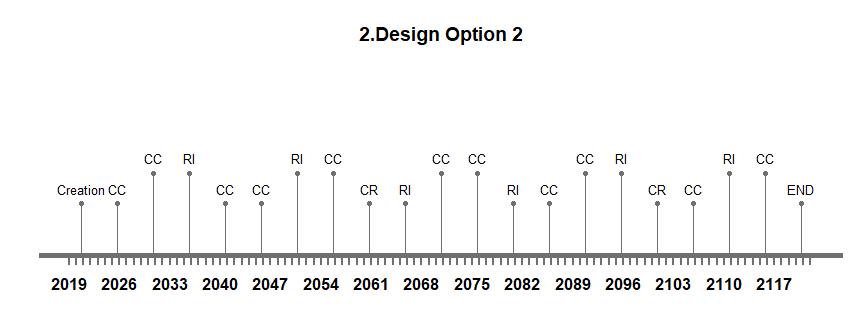

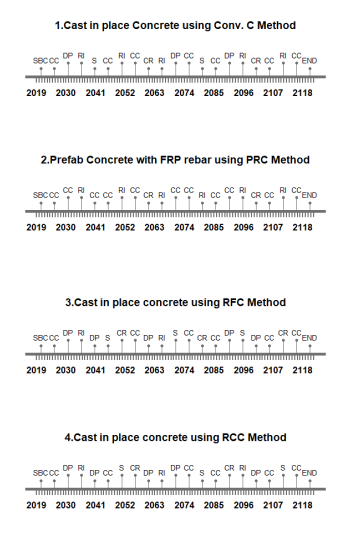

To create the timeline of design options, the materials consumption during the major interventions, such as repairs, replacements, and maintenance works are taken into account.

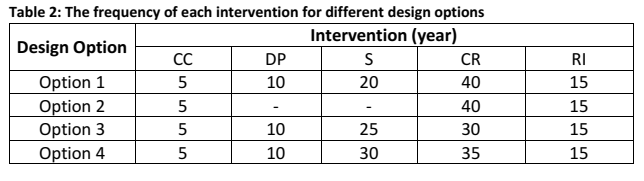

Coating compounds (CC) are used to prevent the flow of water into or out of concrete. For thin repairs, the dry-pack (DP) method can be used on small holes in new concrete. Thick repairs include shotcrete (S) and Concrete Replacement (CR). To repair crack and water leaks, resin injection (RI) is used.

The start date of the analysis (SBC) is assumed to be 01/01/2021 and the lifetime of the stilling basin is also considered 100 years. The Life-Cycle timelines of each design alternatives are generated in R code and shown in Fig. 4.

Life Cycle Inventory and Analysis

The life cycle inventory of different materials used in the construction of the stilling basin is shown. The unit amount represents the quantity of the raw materials required to produce 1 cubic meter of concrete.

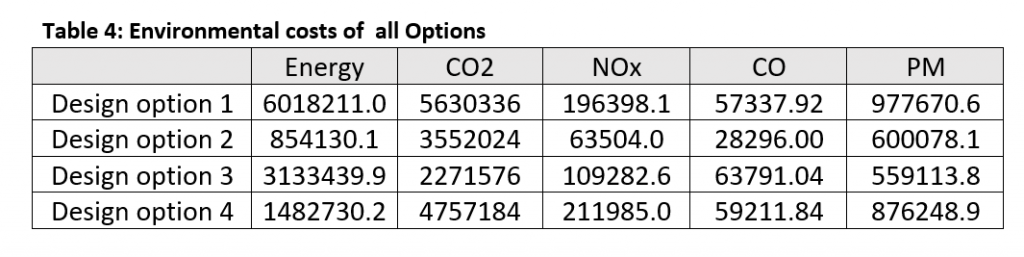

Environmental costs of Options

The levels of each indicator are created and it can be seen that design option 2 has the lowest level of most of the indicators and can be the best choice for the construction of stilling basin.

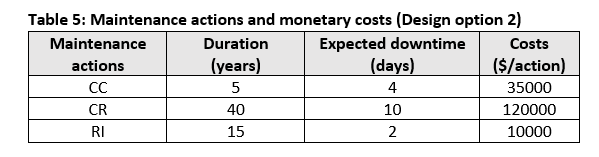

Considered maintenance actions and monetary costs

The expected downtime and the costs are estimated by engineered experience. The different interventions because of maintenance are visualized in a timeline below.