Our project is composed of three common modes of transportation, including a load-bearing member, so creating a non-traditional, very energy-efficient, environmentally friendly, space-saving transportation hub was our main motivation.

We chose the bridge as our central hub and the other three structures as auxiliary hubs.

As we all know, the cable car is mainly used as a viewing vehicle, with a slower speed and a higher altitude, and is mainly used by pedestrians or tourists.

Bridges serve as lower-altitude transportation for vehicles, pedestrians, and even trains.

As a high-speed mode of transportation, trains allow pedestrians to reach their destinations quickly.

Combining the above points, when we want to build a transportation hub that occupies a small area and saves resources, I have designed the following three combinations:

1, The combination of bridge and cable car:

The pylone of the cable car can be used as the pillar of the bridge at the same time;

2, The combination of bridge and retaining wall:

Retaining walls can also serve as support for bridges;

3, Combination of bridge and track:

Where the bridge deck can support the railway track.

In order to achieve an analysis of the above three combinations, first we need a complete list of materials:

| Brick | brick | 1 | 3.56 | 0.271 | 0.05 | 0.1 | 0 |

| Cement | RC | 167 | 3.26 | 0.822 | 0.177 | 0.065 | 0 |

| Fly Ash | RC | 56 | 0 | 0.0025 | 0 | 0.78 | 0 |

| Coarse Aggregates | RC | 1127 | 0.0035 | 0.016 | 0.0018 | 0.0018 | 0 |

| Fine Aggregates | RC | 831 | 0.0023 | 0.0053 | 0.009 | 0.009 | 0 |

| Reinforcement | RC | 135 | 2430 | 225 | 0.71 | 1.85 | 0 |

| Steel | steel | 1 | 2430 | 225 | 0.71 | 1.85 | 0 |

| Cement | RC | 167 | 3.26 | 0.822 | 0.177 | 0.065 | 0 |

| Fly Ash | RC | 56 | 0 | 0.0025 | 0 | 0.78 | 0 |

| Coarse Aggregates | RC | 1127 | 0.0035 | 0.016 | 0.0018 | 0.0018 | 0 |

| Fine Aggregates | RC | 831 | 0.0023 | 0.0053 | 0.009 | 0.009 | 0 |

| Reinforcement | RC | 135 | 2430 | 225 | 0.71 | 1.85 | 0 |

| Cement | PRC | 504 | 3.26 | 0.822 | 0.177 | 0.065 | 0 |

| Coarse Aggregates | PRC | 1050 | 0.035 | 0.016 | 0.0018 | 0.0018 | 0 |

| Fine Aggregates | PRC | 555 | 0.0023 | 0.0053 | 0.009 | 0.009 | 0 |

| Brick | BR | 880 | 2.73 | 0.232 | 0.02 | 0.002 | 0 |

| Cement | BR | 60 | 3.26 | 0.822 | 0.177 | 0.065 | 0 |

| steel cable | SH | 78.5 | 121413.6 | 56005.35 | 0 | 106.967 | 12.01593 |

| steel | steel | 78.5 | 121413.6 | 56005.35 | 0 | 106.967 | 12.01593 |

| concrete | RC | 25 | 5.7487 | 3.67245 | 0 | 0.00542 | 0 |

| cement | RC | 16 | 93.76 | 77.12 | 0 | 0.12624 | 0.014176 |

| Polyester resin laminated part (GFRP, 30% glass fibres) | SA | 1400 | 2327.22 | 6421.94 | 0 | 9.3856 | 0 |

| Polyethylen hoher Dichte | FH | 2100 | 106960.4 | 30736.02 | 0 | 137.9753 | 0 |

| Ballast | BT | 1127 | 0.0035 | 0.016 | 0.0018 | 0.0018 | 0 |

| Asphalt Cement | BT | 167 | 3.26 | 0.822 | 0.177 | 0.065 | 0 |

| Steel | BT | 1 | 2430 | 225 | 0.71 | 1.85 | 0 |

| Steel | RH | 1 | 2430 | 225 | 0.71 | 1.85 | 0 |

| Steel | ST | 1 | 2430 | 225 | 0.71 | 1.85 | 0 |

| Wood | ST | 56 | 0 | 0.0025 | 0 | 0.78 | 0 |

| Cement | FST | 504 | 3.26 | 225 | 177 | 65 | 0 |

| Fine Aggregates | FST | 831 | 0 | 0.01 | 9 | 9 | 0 |

| Steel | FST | 1 | 2430 | 225 | 0.71 | 1.85 | 0 |

The following result is then calculated based on the basic cost:

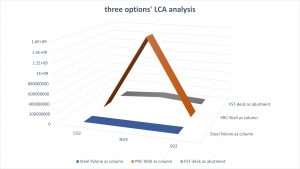

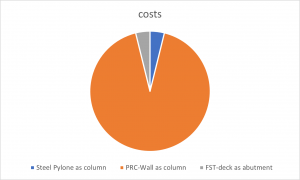

| CO2 | NOX | SO2 | costs | |

| Steel Pylone as column | 691787 | 283325 | 661228 | 1.77 |

| PRC-Wall as column | 16602880 | 1572364883 | 15869462 | 42.5 |

| FST-deck as abutment | 691786.7 | 65515203 | 661227.6 | 1.77 |

Combined with the above analysis, we can get that the retaining wall as a bridge support will cost a lot and produce relatively more polluting gases, we can no longer consider this scheme, but the emission results and cost of the other two schemes are very good. It can be seen that in the analysis of the overall LCA, the transportation hub can fully meet our energy-saving and environmental protection requirements and purposes.