Shipping Container Building Parametric Model

- Introduction

Shipping containers are standardised, modular structures primarily designed for the efficient transport of goods across various modes of transportation. Over the years they evolved to serve diverse purposes not just logistics, including temporary to permanent buildings for various uses[1]. Its durability, flexibility and ability to be easily transported and stacked gives it a huge advantage and make it popular in the AEC industry nowadays[2].

Despite the advantages, it brings some challenges as well, particularly in terms of energy efficiency, transportation, acoustic challenges and insulation[3,4]. The goal of this assignment is to analyze the relationship between key parameters of the shipping container and chosen high performance criterias by developing a parametric model of shipping container building in Dynamo BIM. After maximum exploration of design space, at the end three best alternatives will be proposed based on analysis.

- Design Challenge, Criteria & Parameters

Proposed design challenge for this assignment is to find best possible parameters for transforming shipping containers into energy efficient mobile emergency shelters without specific spatial requirements.

Parameters identified for parametric model of shipping container building are;

1. Length of shipping container

2. Width of shipping container

3. Height of shipping container

The chosen high performance criterias are;

1. Total heat loss over shipping container surfaces(combining walls, roof and floor)

2. Ventilation requirement

3. Energy sufficiency ratio

Every design alternatives of shipping containers will have different heat loss based on their parameters. The thermal performance of the container’s envelope directly affects the indoor comfort, energy consumption and overall energy efficiency of the design. So, minimizing the heat loss is crucial. Ventilation requirement is also closely related to that. The lesser the ventilation needed, the more energy efficient the container design will be. Energy sufficiency ratio(ESR) is another aspect of it. This ratio denotes the potential of the particular shipping container to be powered by solar energy. Which means a design option with greater ESR is more preferable. Every high performance criterias explained has a direct relationship with the chosen parameters. These relationships are described well in the model.

This model could help in answering following questions;

1.What are the optimal design parameters of shipping containers when it is converted into an energy efficient mobile emergency shelter?

2. What are the values of heat loss through the entire envelope, wall, roof or floor? What if the solar radiation is varying?

3. What are the ventilation needs to be fulfilled for each design choice?

4. Which alternative has the highest possibility to be solely powered by solar energy?

- Parametric Model Logic

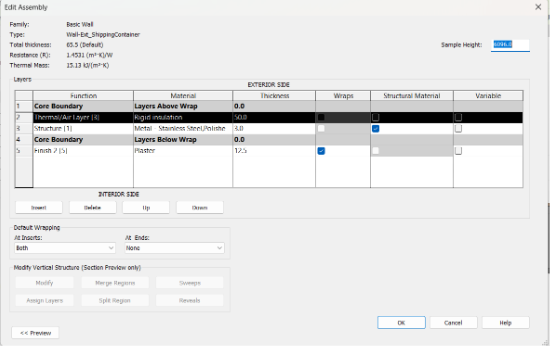

The parametric model of shipping container building in Dynamo BIM is developed to explore design variations by dynamically adjusting the identified parameters. The logic starts from defining a range of possible parameters: length, width and height of the container in mm. From there roof, walls and floor are created and windows and a door are added. Besides, dimensions and type of door and window are fixed, which leads to fixed opening areas. A customized wall type is created, which is not perfect but closely comparable to the actual shipping container properties shown in Figure 1. Same valid for roof and floor.

Figure 1: Customized wall type for shipping container

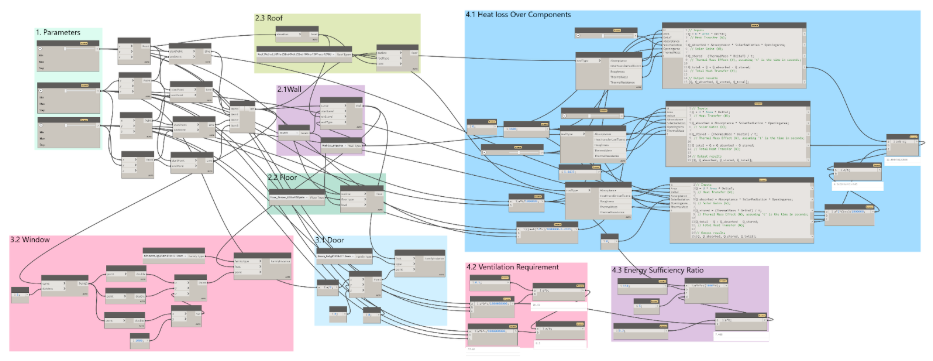

Environmental data inputs such as solar radiation[5], sunlight hours[6], air changes per hour[7], temperature difference between indoor and outdoor are also integrated in the model, which can be possibly varied based on weather. Other inputs are also added like solar panel efficiency[8] and energy demand per day. For each high performance criteria, necessary code blocks are created and calculations are done. To make the script, easily understandable smaller groups with sequential step numbers are also tagged along. So, a user can easily change the parameters of containers(group numbered 1) and get the output (numbered 4.1, 4.2, 4.3). The work space of Dynamo looks like in Figure 2.

Figure 2 : Final image of workspace of Dynamo BIM

Figure 2 : Final image of workspace of Dynamo BIM

- Alternatives Explored

Unlike normal buildings, shipping containers are not available in an indefinite number of shapes. In total, eight options which are potentially possible[9] to use for living purposes are explored and listed in Table no.1. Different sets of parameters can be selected conveniently using number slide nodes of container length, width and height.

Table No.1 : List of alternatives studied

From the table it can be noticed that option 1 has the most compact shape, whereas option 8 has the most enlarged shape. Options 2, 4, 7, and 8 have the head clearance like normal buildings. At the same time, options 5, 6, 7 and 8 have the maximum length which gives more space for different activities.

- Discussion

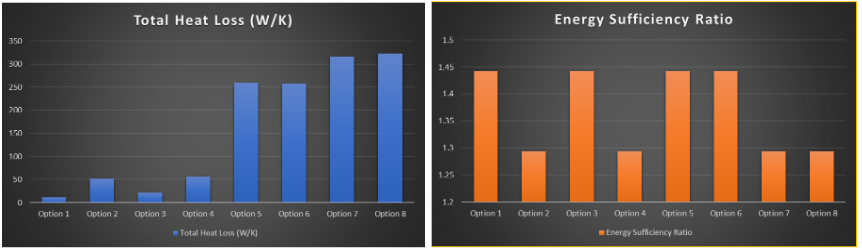

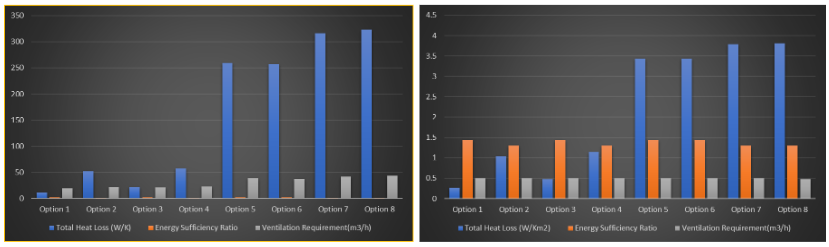

Based on the total heat loss over the envelope of shipping containers(see Figure 3), overall option1 seemed to be the best possible option and option 8 was the worst. However out of 12 metered(length) shipping containers, option 6 shows best results. Where option 4 is the least thermally efficient among 6 metered choices.

If we are relying on solar energy, every container as a single unit building is capable of producing surplus energy. Options 3, 5, and 6 are the most capable container choices out of 8 varieties(see Figure 4). Here option 1 also has a comparable value of this ratio.

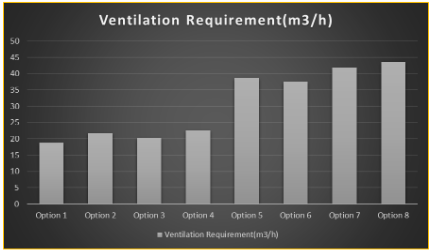

When it comes to ventilation needs(see Figure 5), again option 1 is the best and option 8 is the worst. Option 2 is the which needs highest ventilation and option 6 requires the least amount of ventilation for 6 metered and 12 metered containers respectively. A general overview of results is shown in Figure 6.

Figure 3 : Bar graph total heat loss of each design options Figure 4 : Bar graph energy sufficiency ratios of each design options(left to right)

Figure 3 : Bar graph total heat loss of each design options Figure 4 : Bar graph energy sufficiency ratios of each design options(left to right)

Figure 5 : Bar graph ventilation requirement of each design options

Figure 6 : Bar graph with all the values of high performance criterias of each design options, Figure 7 : Bar graph all the normalized values of high performance of criterias of each design options(left to right)

Figure 6 : Bar graph with all the values of high performance criterias of each design options, Figure 7 : Bar graph all the normalized values of high performance of criterias of each design options(left to right)

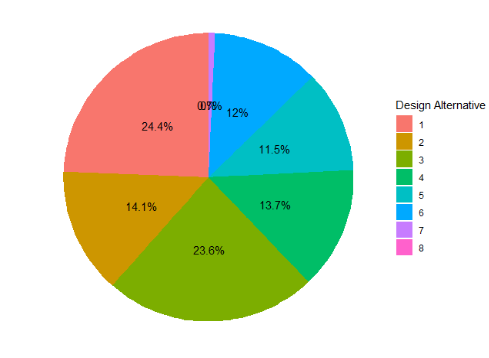

To find the good three alternatives, a simple multicriteria analysis is conducted in R and results are illustrated on Figure 8.

- Conclusion & Future Scope

At the bottom line out of 8 design options explored option 1, 2, and 3 have the good set of parameters based on the MCA. Note that this is solely based on the proposed design challenge to find best possible parameters for transforming shipping containers into energy efficient mobile emergency shelters. No spatial constraints of shipping containers are considered under this study.

All these good alternatives possess overall lowest heat losses and ventilation needs. Which means total energy consumption of these buildings will decrease. Both 1 and 3 options have two of the highest values of energy sufficiency ratios, whereas option 2 has lower value compared to others. Despite this, comparing overall performance option 2 still stays in the top 3 good alternatives.

Figure 8 : Ranking of design alternatives based on selected high performance criteria

This developed parametric model could have more potential if the scope is broadened. The opportunity to alter solar radiation value, insulation type, element(windows and doors) types, ventilation modes, area of ventilation, temperature difference and all the given input values would possibly help the model to adapt to different design scenarios and scope.

[1] Antoni Willem Botes, 2013, A feasibility study of utilising shipping containers to address housing backlog in Africa.http://hdl.handle.net/10019.1/85714

[2] Pakinam Nabil Barakat, 2022, Reshaping Future Architecture Approaches Using Shipping Containers: Student Housing as a Case Study, International Journal of Sustainable Development and Planning, https://www.researchgate.net/publication/366943884

[3] Kevin Giriunasa, Halil Sezena, Rebecca B. Dupaix, 2012, Evaluation, modeling, and analysis of shipping container building structures, Engineering Structures 43 (2012) 48–57, https://doi.org/10.1016/j.engstruct.2012.05.001

[4] Hamidul Islam, Guomin Zhang, Sujeeva Setunge, Muhammed A. Bhuiyan, 2016, Life cycle assessment of shipping container home: A sustainable construction, Energy and Buildings 128 (2016) 673–685, https://doi.org/10.1016/j.enbuild.2016.07.002

[5] Global, diffuse and direct radiation (monthly and annual totals and deviations) https://www.dwd.de/EN/ourservices/solarenergy/maps_globalradiation_sum_new.html

[6] Sunrise and Sunset Calculator — City Lookup https://www.timeanddate.com/sun/

[7] What is the Correct Ventilation Rate in Buildings, Sterispace, https://sterispacesystems.com/community-involvement/what-is-the-correct-ventilation-rate-in-buildings/

[8] Solar-cell efficiency, https://en.wikipedia.org/wiki/Solar-cell_efficiency

[9] Mohammad Ataei, 2016, Design of two story shipping container building, Master thesis work.

https://doi.org/10.1007/s10694-021-01143-9

Main Page I Introduction I Individual Systems I Integrated Ontology I Integrated Parametric Model