Layout Optimization for Operational Uses and Sustainability: A Parametric Approach to an Industrial Complex for Vehicles

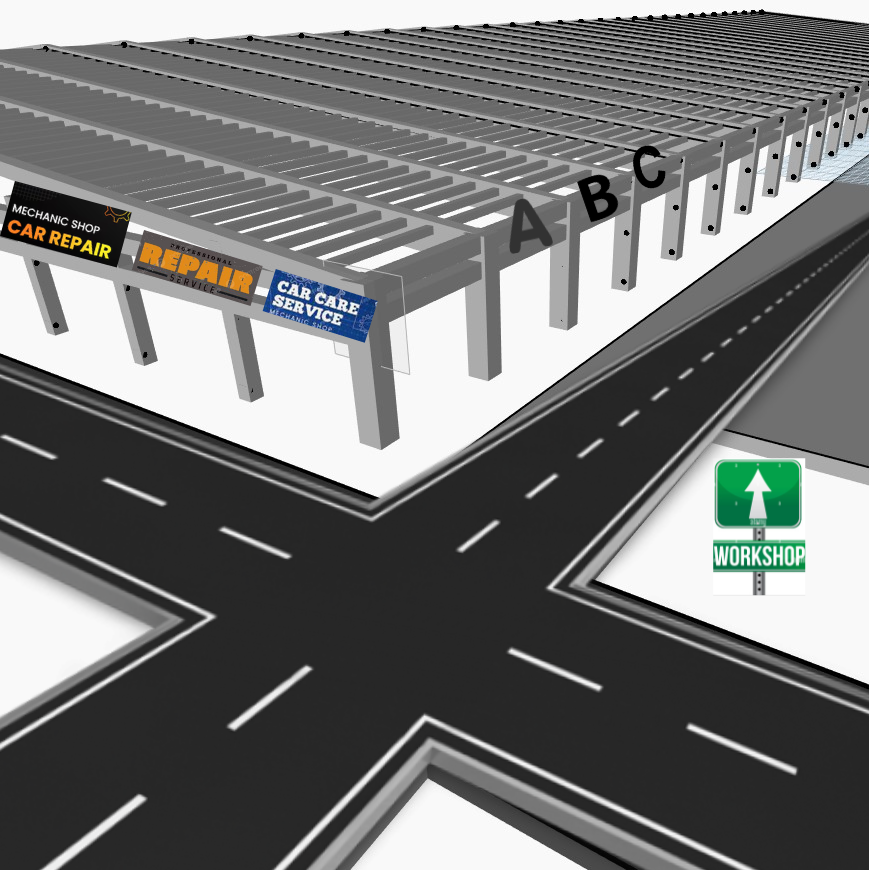

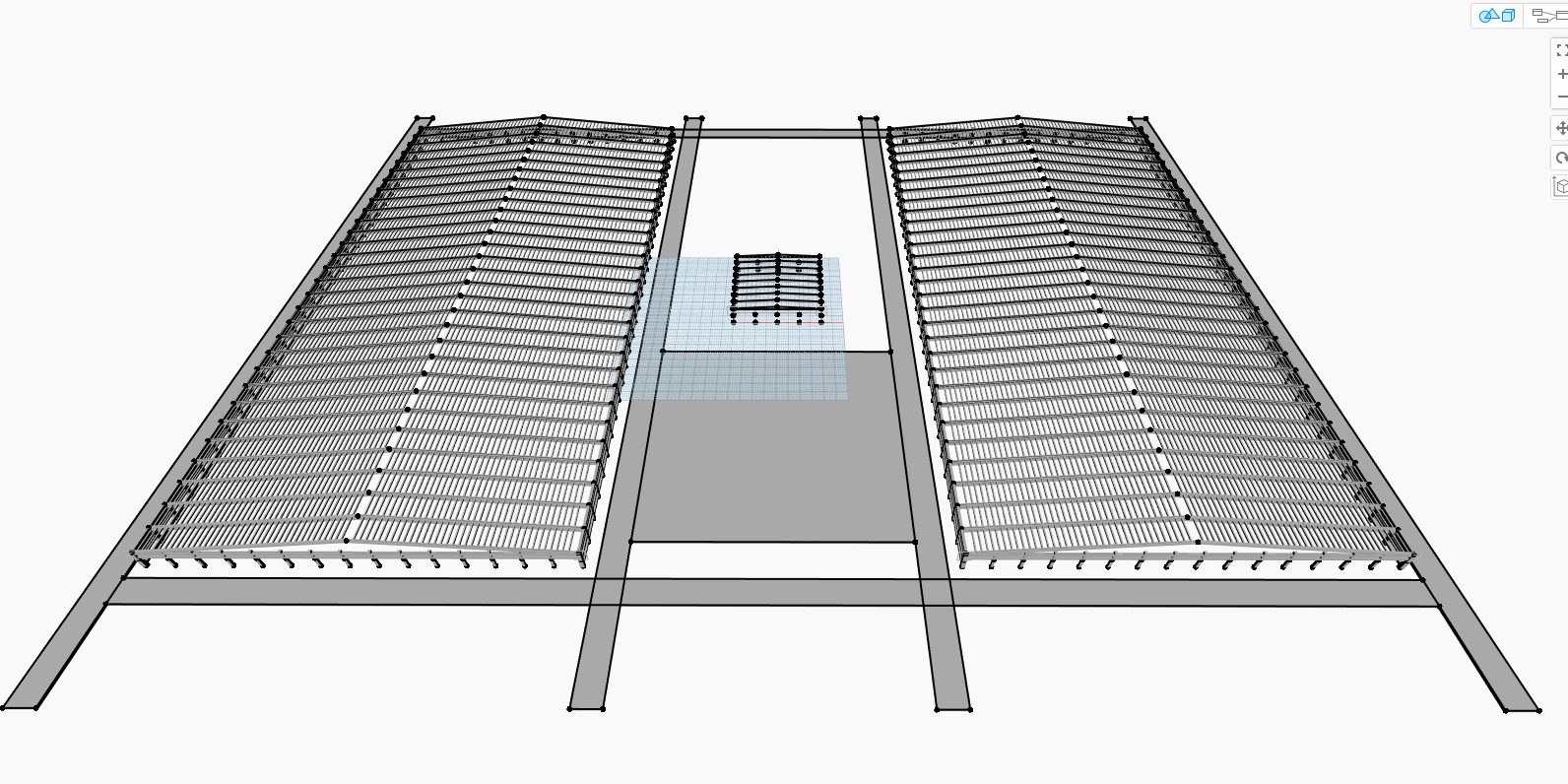

As we know parametric modeling provides a systematic approach to optimizing the industrial complex layout by leveraging computational design methods to enhance operational efficiency and sustainability. By defining key parameters such as building placement, traffic circulation pathways, and accessibility, the model ensures an adaptive and efficient layout for an industrial site for vehicle maintenance and repair. For this project, where our primary challenge was to define an optimal configuration for two warehouses, a vehicle workshop, and an amenity building, a parametric approach was employed to ensure seamless interaction between functional zones while minimizing inefficiencies. Given that our larger buildings were designated as vehicle workshops and the smaller ones as amenity spaces, parametric modeling allowed for iterative testing of different configurations to optimize layout, traffic circulation, accessibility, and land utilization.

Design Challenge

The design challenge was “Layout Optimization for Operational Use and Sustainability” inside an industrial complex for vehicle repair mainly and eliminate layout and traffic flow issues for our integrated complex while focusing on maximizing operational efficiency and ensuring seamless interaction between the two industrial buildings, one amenity building, parking areas, and surrounding road networks. As in our model, the two large warehouses serve as the primary functional spaces, strategically positioned to facilitate efficient workflow, vehicle movement, and logistical operations. Their placement allows for direct access to the main road, minimizing unnecessary detours and ensuring a smooth transition for incoming and outgoing vehicles. The amenity building, located near warehouses, serves as a multi-purpose support facility, offering waiting areas, break zones, and additional storage for workers and visitors but having an optimal layout is always the challenge.

High-Performance Criteria

As the design challenge was to optimize the layout for operational use inside an industrial complex for vehicle repair mainly and eliminate these common issues already discussed in the integration context and try to achieve the most efficient, and sustainable industrial complex for operational use. To address these issues, we have implemented these key design considerations.

Singular Buildings – Multiple Uses

- For different companies and shops, the larger buildings can be used and can be separated by drywall partitions easily. Therefore, these 2 large buildings will be 2 giant complexes for shops this gains us;

- Construction material savings due to single frame and partition approach.

- Energy savings due to the centralized HVAC system.

Fig.1 Vehicle Workshops in a Vehicle Complex

Traffic Congestion and Idle Vehicles Storing

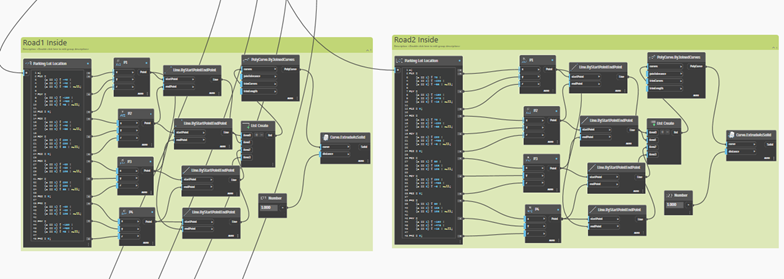

- 3-Different Layout Options that are in our Dynamo Model were evaluated considering the easiest access from all components to each other, with minimum intersections. This is then evaluated in the conclusion and discussion section.

- Added a parking lot for idle vehicles and waiting vehicles to reduce congestion

- Made the roads a minimum of 10 meters wide, considering traditional two-way roads are 7.5 meters, this leaves a space on the side of the road throughout the side to park cars.

Fig.2 Traffic Flow Layout for our Industrial Complex

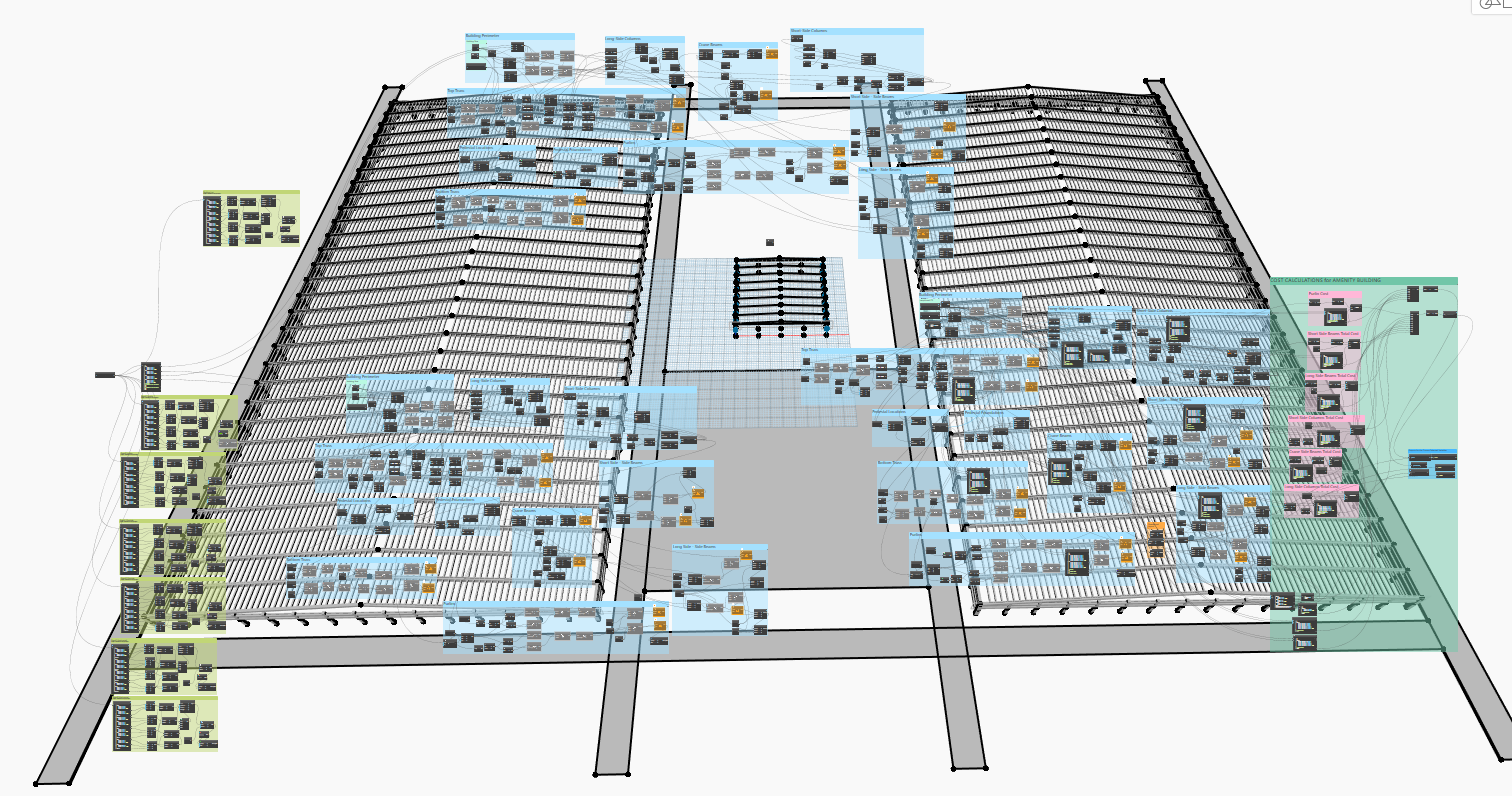

Logic of the Model

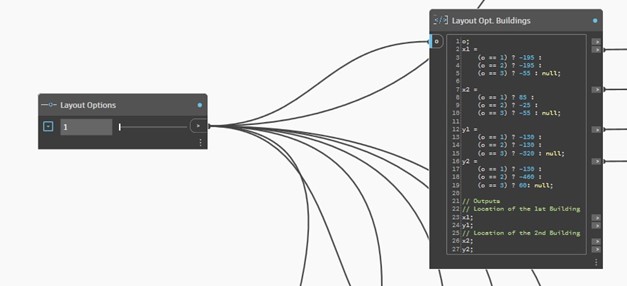

The model works with a number slider for design options and clauses connected to these design options created in code blocks.

Fig.3 Number Slider for Layout Options and Code Block for Options

Code blocks move the location of all the components, creating different layout options. All the components such as roads, parking lots, and buildings are created in the same logic, resulting in a coherent model.

Fig.4 Code Blocks with Alternatives for Different Layout Options

Here is a complete script with all the logic and components that can be used for creating the different layout options (Option 1 is displayed in this image):

Fig.5 Final Script with Design Layout Option 1

Design Alternatives

Following are the three Design Alternatives we have in our parametric Model:

1. Grid Layout (Layout Option 1)

2. Diagonal Layout (Layout Option 2)

3. Parallel Layout (Layout Option 3)

Discussion of Design Alternatives and Conslusion

Our discussion is based on the comparison of the following layout options below:

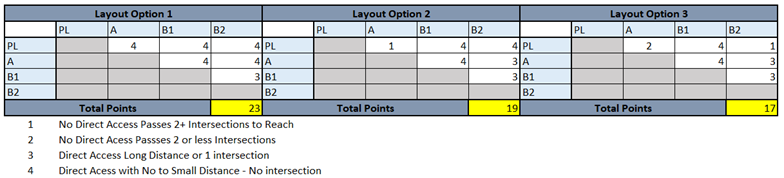

Fig. 6 Accessibility Comparison Index

To reach the design goal which is to come up with the most efficient and sustainable design in the limitations of the operational use. Some of the considerations we had are very straightforward and easy to evaluate. Such as having a singular building separated by partitions to reduce energy consumption and construction material. Alterations we have done to reduce congestion, and therefore the fuel and energy spent. However, the layout of the industrial site needed further investigation. To evaluate our options with some mathematical context too we have implemented the system on the table. This table gives a point per accessibility from each component of the system to the other with respect to the points and descriptions below the table. Then the overall points represent the overall evaluation of accessibility from building to building. Results matched with our evaluation, the ranking system showed that the best option is Layout Option 1.

Fig. 2 Best Layout Option

The evaluation system we have applied can be enhanced by multiple approaches. Our team was not able to conduct this due to the lack of data, and research on the topic. However, if the probability of each car going from one component of the system to the other can be obtained, then a Markov chain can be implemented to get the importance of each option i.e. PL to A, B1 to B2, etc. Then this evaluation would be more accurate, and the final layout consideration may change. However, the ease of access from all buildings to others, and outside roads that enable one to go from the exit to the entrance makes option 1 a solid option.

References

- Warehouse Layout Design Principles.” Logistics Bureau, 15 Nov. 2023, logisticsbureau.com/warehouse-layout-design-principles

- De Weck, Olivier L. “Multiobjective Optimization: History and Promise.” Proceedings of CJK-OSM3, 2004, Kanazawa. Massachusetts Institute of Technology. https://scholar.google.de/citations?view_op=view_citation&hl=de&user=GFEciiAAAAAJ&citation_for_view=GFEciiAAAAAJ:0EnyYjriUFMC

- Farias, Arthur Almeida Cordeiro de, et al. “Analysis and Design of Structural Elements of an Industrial Steel Warehouse with Overhead Crane.” International Journal of Engineering Research and Applications, vol. 12, no. 2, (2022).

- “Stahlpreisindex.” Stahl Kompakt, https://www.stahl-kompakt.de/SK.Premium/Stahlpreisindex.aspx. Accessed 8 Jan. 2025.

- Eurocode 0: European Committee for Standardization. EN 1990: Eurocode – Basis of Structural Design. December 2005, incorporating corrigenda December 2008 and April 2010.

- Eurocode 1: European Committee for Standardization. EN 1991-1-1: Eurocode 1: Actions on Structures – Part 1-1: General Actions – Densities, Self-weight, Imposed Loads for Buildings. April 2002, incorporating corrigendum March 2009.

- Eurocode 3: European Committee for Standardization. EN 1993-1-1: Eurocode 3: Design of Steel Structures – Part 1-1: General Rules and Rules for Buildings. May 2005, incorporating corrigenda February 2006 and March 2009.

- Eurocode 4: European Committee for Standardization. EN 1994-1-1: Eurocode 4: Design of Composite Steel and Concrete Structures – Part 1-1: General Rules and Rules for Buildings. December 2004, incorporating corrigendum April 2009.

- Eurocode 8: European Committee for Standardization. EN 1998-1: Eurocode 8: Design of Structures for Earthquake Resistance – Part 1: General Rules, Seismic Actions and Rules for Buildings. December 2004, incorporating corrigendum July 2009.

- Euronorm 53-62: Hot Rolled I-Sections – Dimensions and Weights. European Committee for Standardization, 1962.

- Euronorm 19: Rolled Steel I-Sections. EN 19-57. 1957. European Committee for Standardization.

- DIN 1026-1: Hot Rolled Channels – Dimensions, Masses and Static Parameters. DIN 1026-1. 2000. Deutsches Institut für Normung (DIN)

- BS EN 10056-1: Structural Steel Equal and Unequal Leg Angles – Dimensions. BS EN 10056-1. 2017. British Standards Institution (BSI)